ALD heating furnace

A heating furnace and forehearth technology, which is applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as poor uniformity, low deposition efficiency, and long material growth cycle of reactant utilization rate, so as to reduce Waste, improve uniformity, and reduce the effect of polluting cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

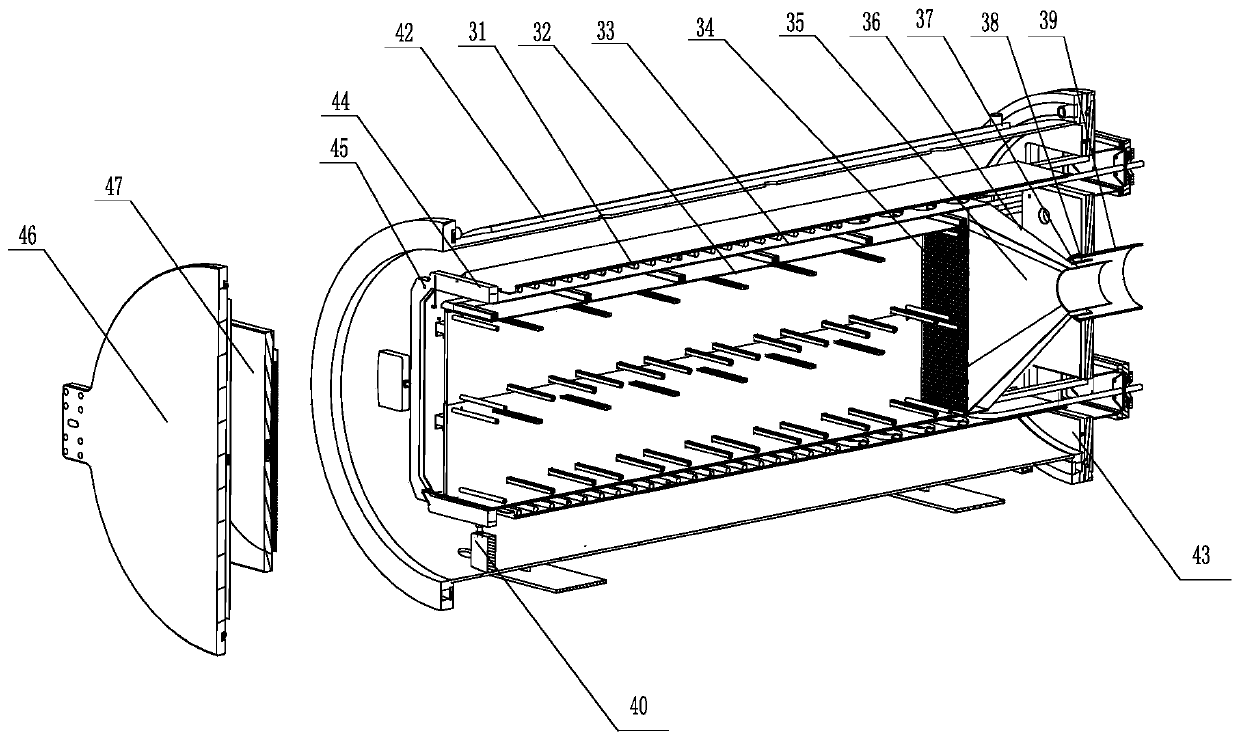

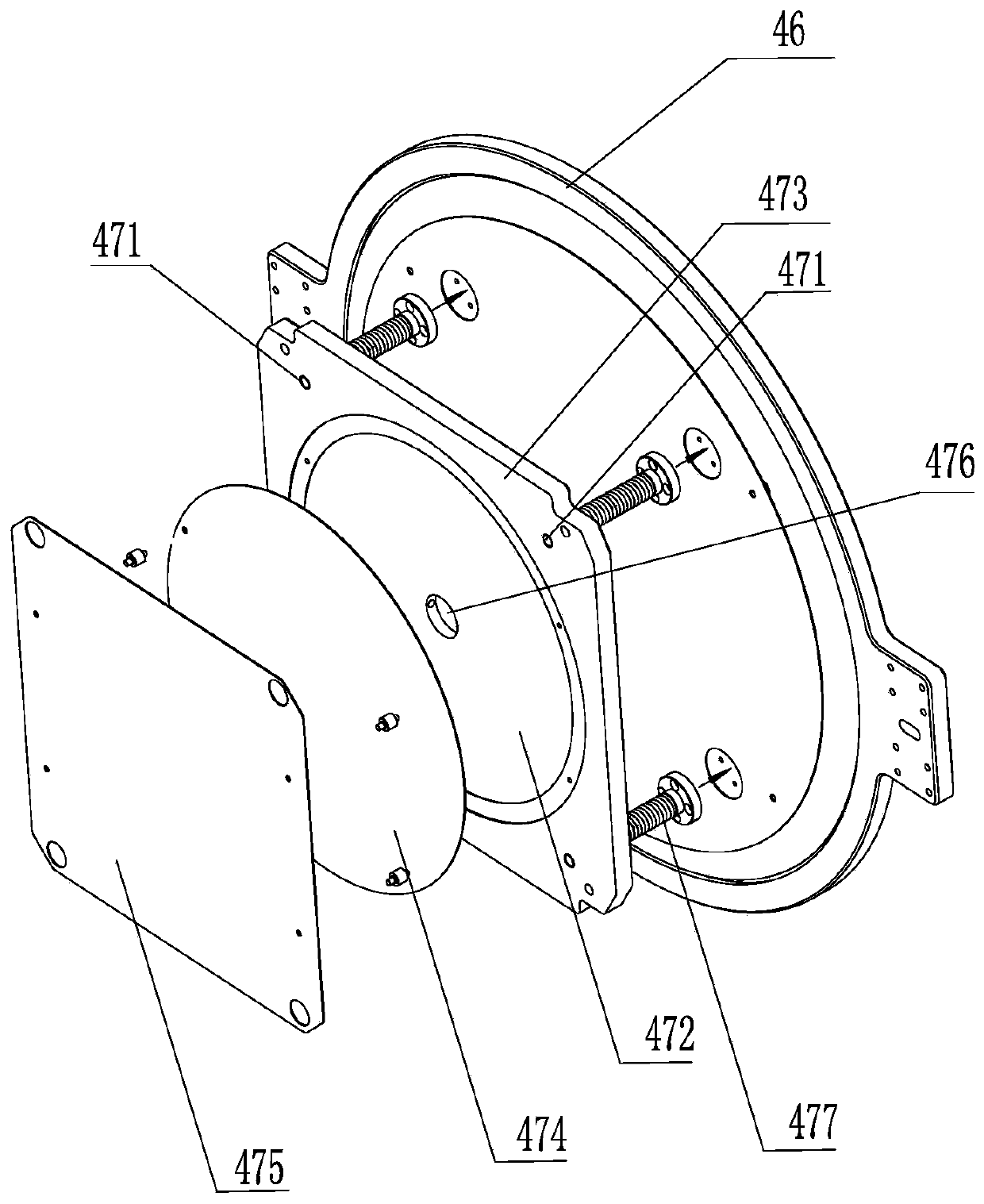

[0016] Such as figure 1 and figure 2 As shown, the ALD heating furnace of the invention itself includes a cylindrical cavity 42, and the two ends of the cylindrical cavity 42 are provided with furnace doors, and a diversion chamber 33 is arranged inside it, and a pair of heating assemblies 31 are arranged on the outer wall of the diversion chamber 33. The inside of the diversion cavity is heated, and the bottom of the diversion cavity is provided with a support member 41 to support the diversion cavity, and a boat body 32 is arranged in the diversion cavity for placing silicon wafers. The air intake assembly 47 is arranged at the front furnace door 46, and the air intake assembly 47 includes a guide chamber door 473, an outer layer equalizer 474 and an inner layer equalizer 475, and the guide chamber door 473 is provided with The conical re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com