Thin-wall type house structure and construction method thereof

A house and thin-walled technology, applied in the thin-walled house structure and its construction field, can solve the problems that cannot be effectively solved, insufficient bulkiness of thermal insulation materials, difference in thermal insulation performance, etc. and durable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

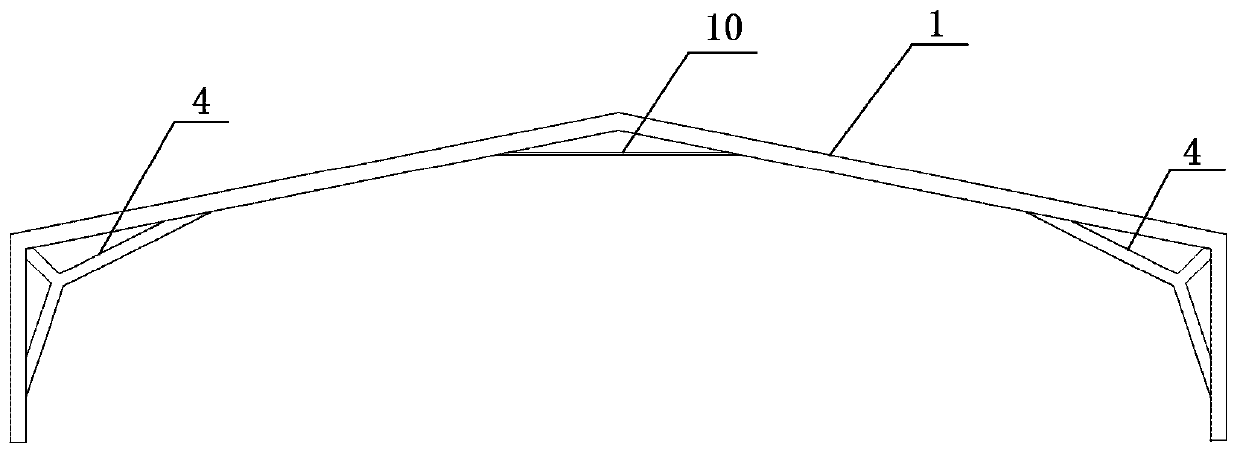

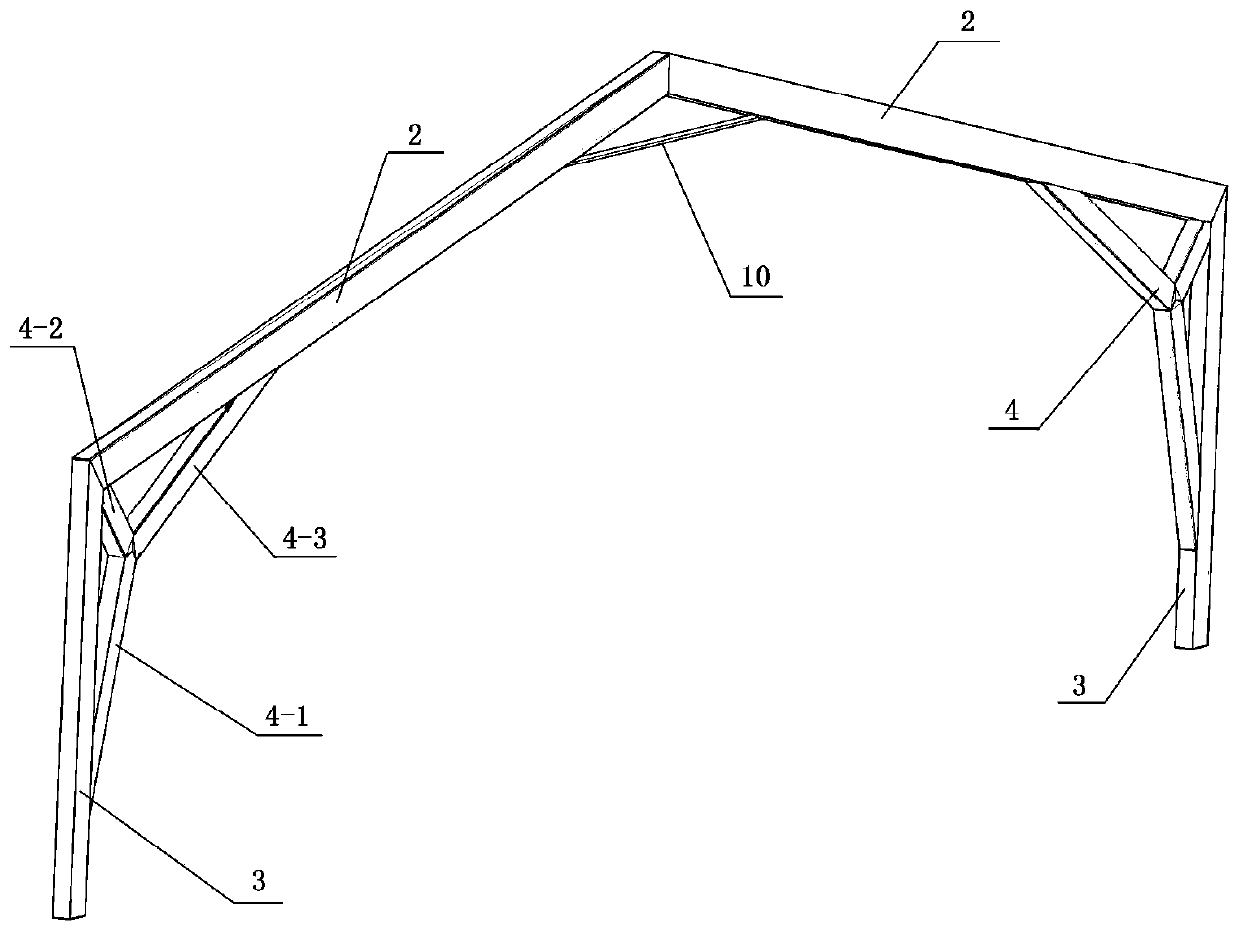

[0040] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 with Figure 14 Describe this embodiment, this embodiment includes a main frame body 1 and a support member, the main frame body 1 includes two beams 2 and two columns 3, the two beams 2 are arranged obliquely side by side, the high ends of the two beams 2 are connected, the two beams 2 The lower ends of each beam 2 are respectively provided with a column 3, and each column 3 is fixedly connected with the end of the corresponding beam 2, the beam 2 is a beam of equal cross section, the column 3 is a cylinder of equal section, and the supporting parts include beams for adding For the haunches and the end corner haunches, the beam haunches are arranged at the high ends of the two beams 2 , and the end corner haunches are arranged between each beam 2 and its correspon...

specific Embodiment approach 2

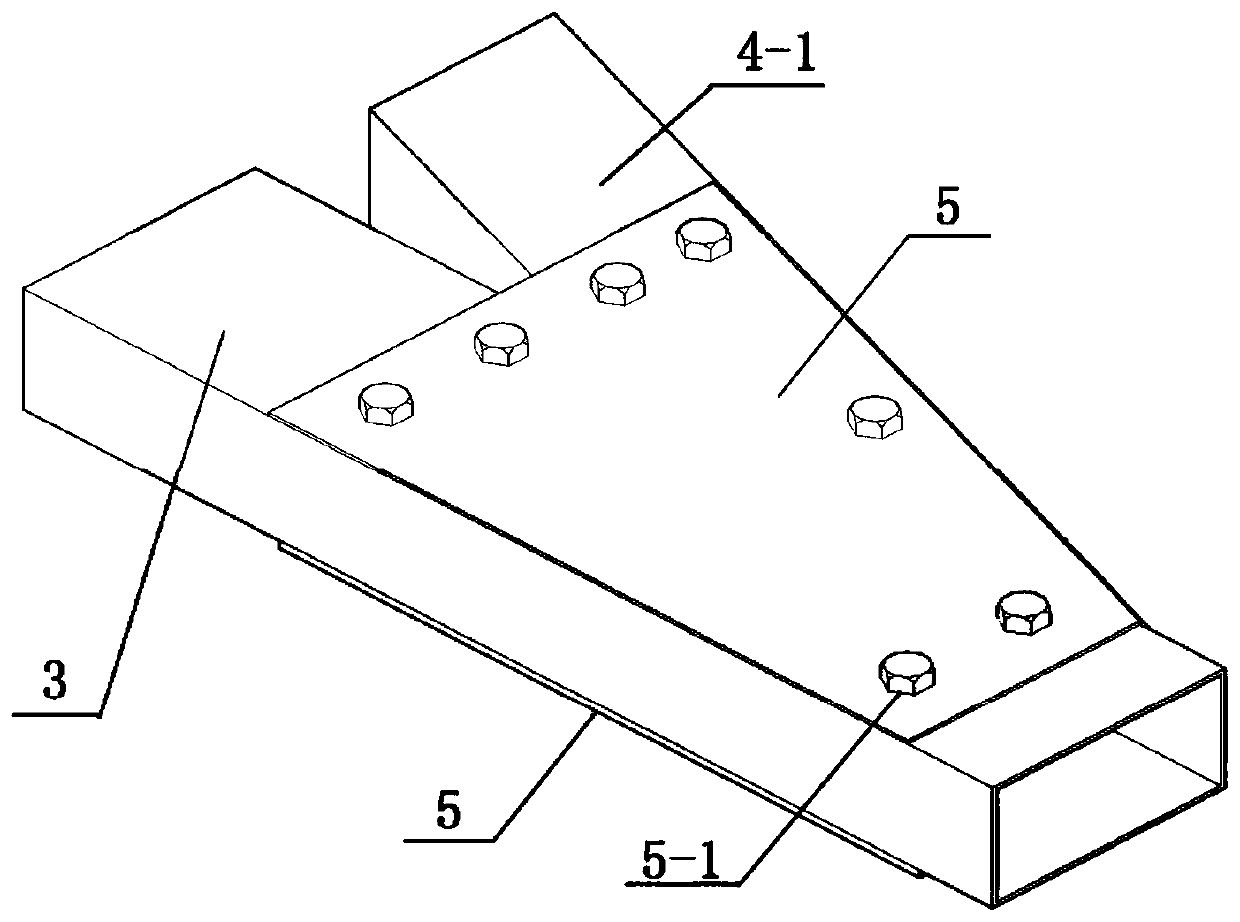

[0042] Specific embodiment 2: This embodiment is a further limitation of specific embodiment 1. The end angle adding armpit is a trident support body 4 or a pressure rod 11 for the end angle, such as figure 1 with figure 2 As shown, when the end angle adding armpit is the trident support body 4 for the end angle, the trident support body 4 for the end angle includes a first support rod 4-1, a second support rod 4-2, and a third support rod 4-3 And two three-fork connecting pieces 4-4, one end of the first support rod 4-1, one end of the second supporting rod 4-2 and one end of the third supporting rod 4-3 pass through two three-fork connecting pieces 4-4 Detachable connection, the other end of the first support rod 4-1 is detachably connected to the column 3, the other end of the second support rod 4-2 is detachably connected between the beam 2 and the column 3, the third support rod 4- The other end of 3 is detachably connected on the beam 2.

[0043] This embodiment has m...

specific Embodiment approach 3

[0051] Specific embodiment 3: This embodiment is a further limitation of specific embodiment 1 or 2, and the said beam with axillary member is a tie rod 10 or a vertical trident support body 12, such as figure 1 , figure 2 , Figure 12 with Figure 15 As shown, when the beam haunching member is a tie rod 10 , the tie rod 10 is horizontally arranged between two beams 2 .

[0052] Such as Figure 13 with Figure 14 As shown, when the armpit for the beam is a vertical three-prong support body 12, the vertical three-prong support body includes a first support column 12-1 and two first oblique bars 12-2, and the first support column 12-1 vertically The two first slanting rods 12-2 are arranged obliquely on both sides of the first support column 12-1 respectively, and one end of each first slanting rod 12-2 is connected to the first support The column 12-1 is fixedly connected, and the other end of each first slanting rod 12-2 is fixedly connected with the adjacent beam 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com