Strengthening Method of Coupling Beam Based on Viscoelastic Material

A viscoelastic material and connecting beam technology, applied in the field of structural engineering, can solve the problems of poor stiffness and energy dissipation of connecting beams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

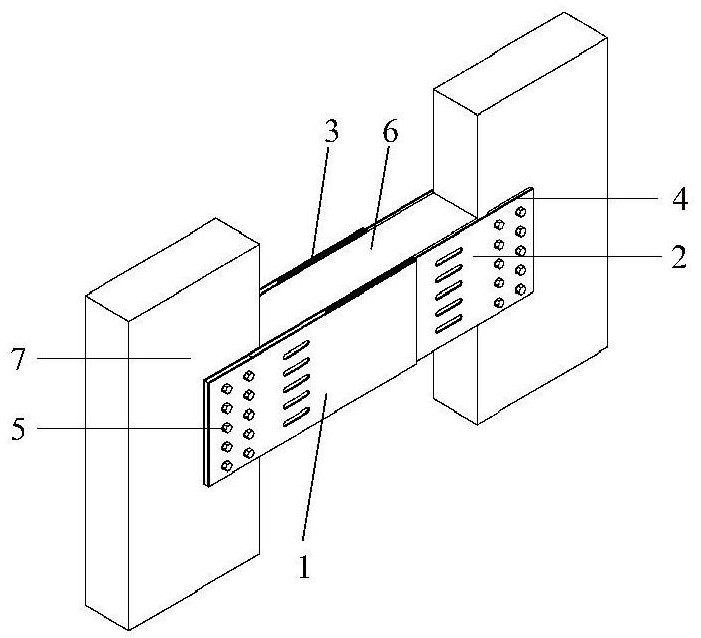

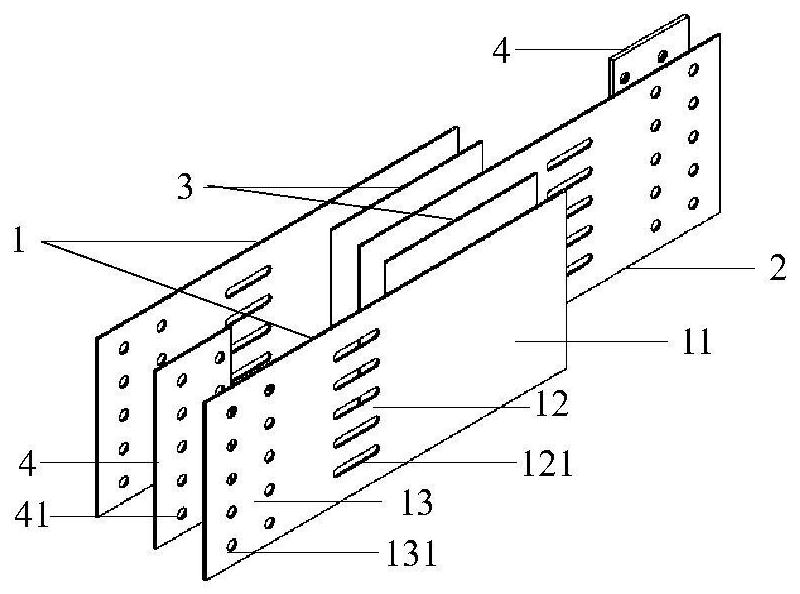

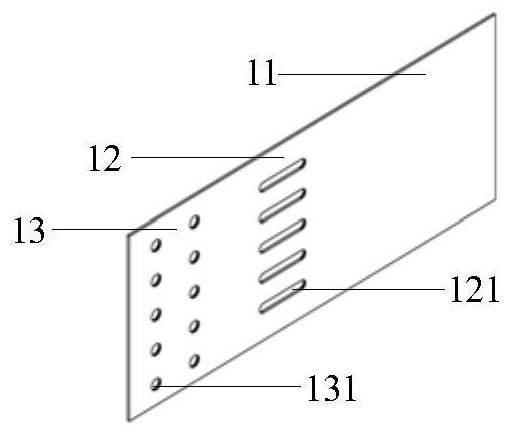

[0035] Such as Figure 1-12 Shown: a connecting beam strengthening method based on viscoelastic materials, the components and materials used include a first steel plate 1 , a second steel plate 2 , a viscoelastic material 3 , a backing plate 4 , and a connector 5 .

[0036] The first step is to process the first steel plate 1 and the second steel plate 2 with circular holes and grooved holes.

[0037] The second step is to alternately distribute the first steel plate 1 and the second steel plate 2, and place a viscoelastic material 3 in the middle;

[0038] The third step is to bond the bonded sections of the first steel plate 1 and the second steel plate 2 with the viscoelastic material 3 .

[0039] The fourth step is to bond the outermost steel plate in the first steel plate 1 to one side of the connecting beam 6 .

[0040] The fifth step is to insert the backing plate 4 into the gap between the first steel plate 1, the second steel plate 2, and the second steel plate 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com