Passenger and freight collinear railway polyurethane microporous base plate and preparation method thereof

A technology of polyurethane, passenger and freight, which is applied in the field of polyurethane microporous pads and its preparation for passenger and freight railways. Stability, small change in static stiffness, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

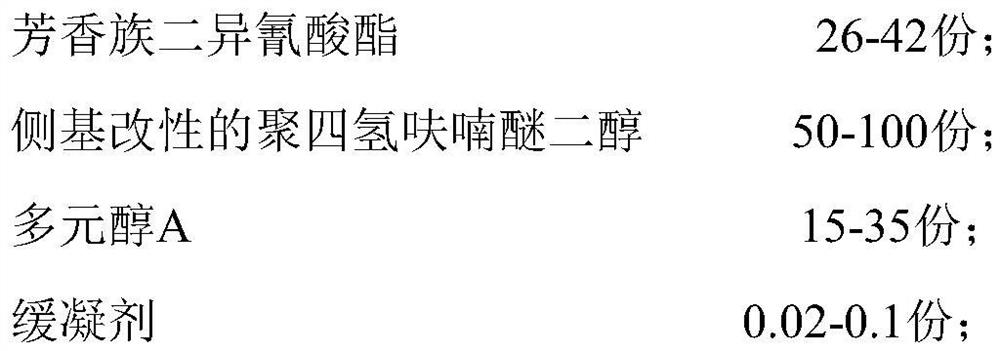

[0058] Preparation of Component A: Weigh 55 parts of methyl-modified polytetrahydrofuran ether diol, 30 parts of polyether polyol 330, add 0.05 parts of phosphoric acid, heat up to 105°C for vacuum (≤-0.095MPa) dehydration for 4 hours, cool down to Add 26 parts of xylylmethane diisocyanate (MDI-100) at 45°C, react at 85°C for 4 hours, cool down to 50°C, and pack for use.

[0059] Preparation of component B: Add 35 parts of methyl-modified polytetrahydrofuran ether diol and 7 parts of 1,4-butanediol into the reaction kettle, and raise the temperature to 105°C for vacuum dehydration for 2 hours, then drop the temperature to 43°C, and then add 2 parts of foam stabilizer, 4 parts of catalyst 33LV, 4 parts of catalyst MB20, 0.7 part of water and 0.3 part of blue color paste (phthalocyanine blue series), stir and mix evenly, pack for use.

[0060] Preparation of backing plate: raise the temperature of component A to 45°C, and the temperature of component B to 43°C, mix component A a...

Embodiment 2

[0062] Preparation of Component A: Weigh 100 parts of ethyl-modified polytetrahydrofuran ether diol, 20 parts of polyether polyol 330, add 0.07 parts of phosphoric acid, heat up to 105°C for vacuum (≤-0.095MPa) dehydration for 4 hours, cool down to Add 37 parts of xylylmethane diisocyanate (MDI-100) at 45°C, react at 85°C for 4 hours, cool down to 50°C, and pack for use.

[0063] Preparation of Component B: Add 1.4 parts of 1,4-butanediol into the reactor, heat up to 105°C for vacuum dehydration for 2 hours, then drop the temperature to 43°C, add 5 parts of foam stabilizer, 4 parts of catalyst 33LV, 4 parts 1 part of catalyst MB20, 0.7 part of water and 0.3 part of blue color paste (phthalocyanine blue series), stir and mix evenly, and pack for use.

[0064] Preparation of backing plate: raise the temperature of component A to 60°C, and the temperature of component B to 40°C, mix component A and component B according to the mass ratio of 100:11 and pour them into a mold with a...

Embodiment 3

[0066] Preparation of Component A: Weigh 50 parts of EO modified polytetrahydrofuran ether diol, 20 parts of polyether polyol 330, add 0.05 parts of phosphoric acid, heat up to 105°C for vacuum (≤-0.095MPa) dehydration for 4 hours, cool down to 45 °C, add 37 parts of xylylmethane diisocyanate (MDI-100), react at 90 °C for 4 hours, cool down to 50 °C, and pack for use.

[0067] Preparation of component B: Add 50 parts of EO-modified polytetrahydrofuran ether diol and 5 parts of 1,4-butanediol into the reaction kettle, and raise the temperature to 105°C for vacuum dehydration for 2 hours, then drop the temperature to 40°C, and then add 2 1 part of foam stabilizer, 4 parts of catalyst 33LV, 4 parts of catalyst MB20, 0.7 part of water and 0.3 part of blue color paste (phthalocyanine blue series), stir and mix evenly, and pack for use.

[0068] Preparation of backing plate: raise the temperature of component A to 38.5°C, and the temperature of component B to 39°C, mix component A a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com