Torsion pendulum type low-pressure-loss backing-pressure-reducing while-drilling tool and work method thereof

A torsion pendulum type, low pressure technology, applied in the direction of drilling with vibration, can solve the problems of reducing the effective value of the oscillation force, reducing the friction resistance ability, weak response ability of higher frequency oscillation, etc., to compensate for trace outer diameter wear and reduce sealing friction. Resistance, the effect of improving the effect of decompression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

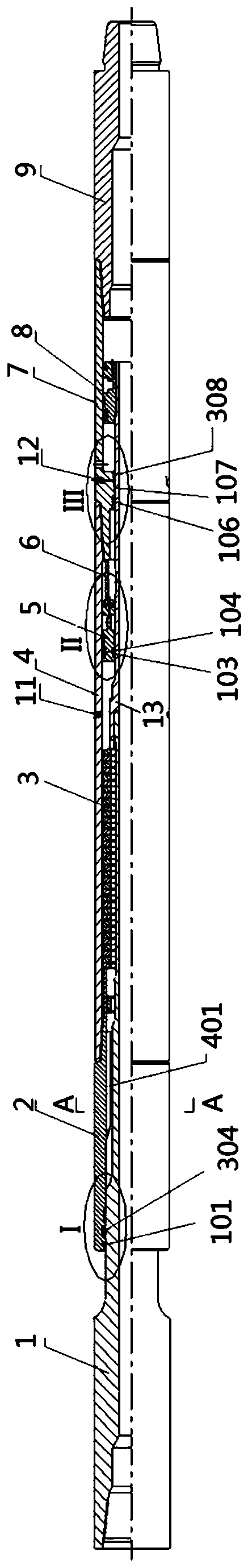

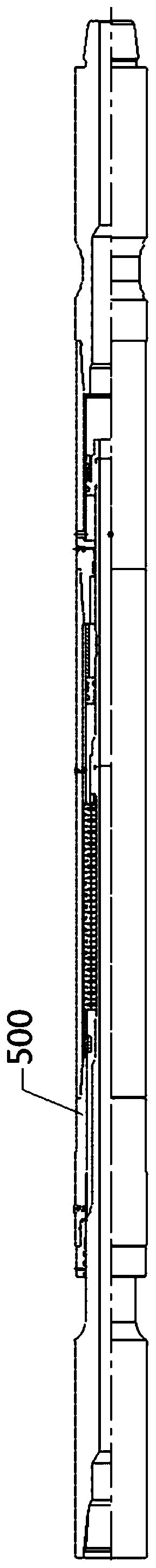

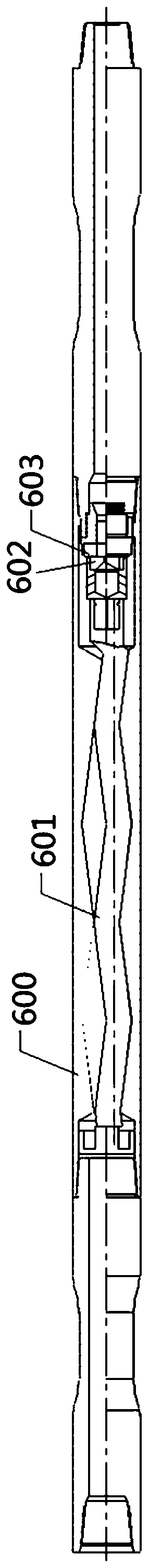

[0047] Such as Figure 1-2 As shown, the torsional pendulum low-pressure consumption pressure-reducing tool-while-drilling tool 500 is composed of a torsional pendulum-axial vibration spline assembly, a balance piston assembly, and a booster piston assembly.

[0048] The torsional pendulum-axial vibration spline assembly is centrally packaged in the oil seal cylinder, the torsional pendulum-axial vibration spline assembly includes a spline mandrel 1, and the spline mandrel 1 is provided with the spline outer cylinder 2 described above. The inner surface of the front end of the key outer cylinder 2 is provided with a front end scraper assembly 101 and a first M-shaped scraper seal ring 304 ; the lower part of the spline mandrel 1 is provided with a disc spring assembly 3 .

[0049] Such as Figure 4-5 As shown, the outer surface of the spline mandrel 1 is evenly distributed with helical splines 401, and the inner surface of the spline outer cylinder 2 is provided with a helical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com