Pipeline robot for detecting underground cable faults

A technology for pipeline robots and underground cables, which is used in the detection of faults, fault locations, and two-dimensional position/channel control by conductor type, which can solve problems such as low detection efficiency and inaccurate map construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

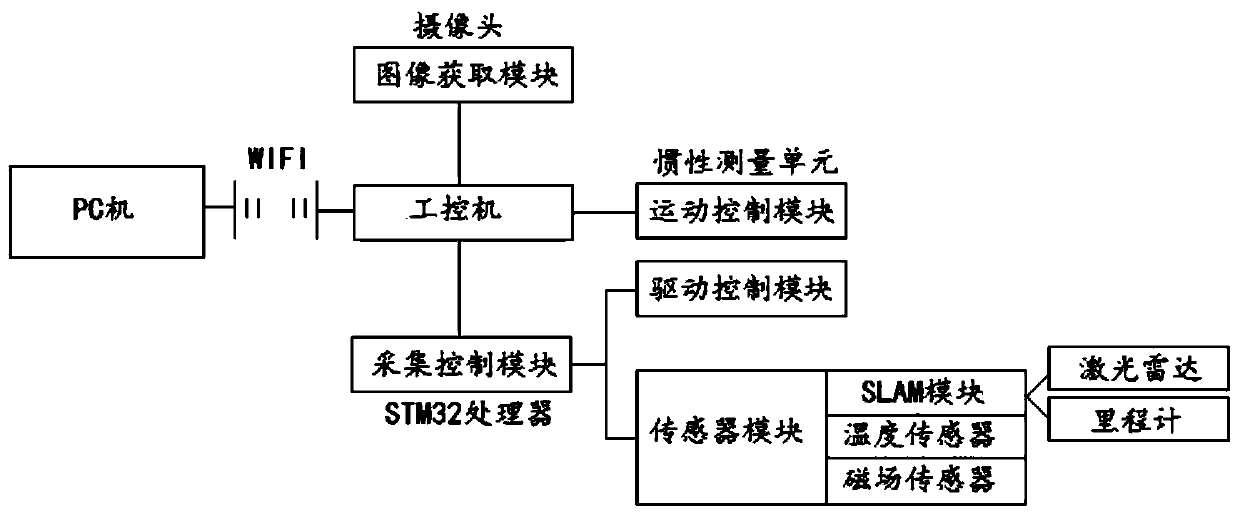

[0071] This application discloses a pipeline robot for detecting underground cable faults. Considering the adaptability to various complex terrains and environments in underground pipelines, the chassis of the robot adopts a crawler structure, that is, the robot uses a crawler chassis as a load and walking mechanism, and various structural modules are arranged above the crawler chassis.

[0072] On the crawler chassis, the crawler drive wheels on both sides adopt a two-wheel differential drive structure. Although the tracked structure is inferior to the wheeled structure in terms of speed, the tracked chassis can rotate in situ by using the differential speed of the two wheels, and has strong passability. It has good performance and stability in uneven underground pipelines and has a long battery life. ability.

[0073] 1. Structural module part

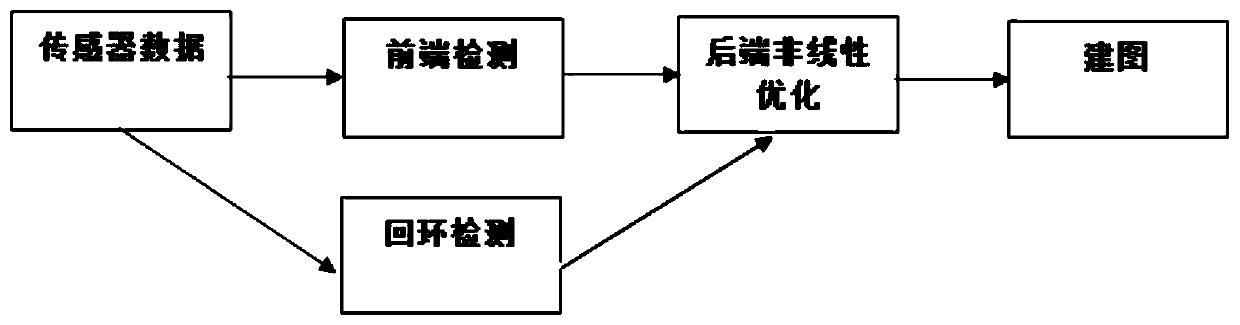

[0074] Such as figure 1 As shown, the robot of this solution is equipped with a sensor module, an acquisition control module, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com