Frame strip nailing machine and nailing method

A technology of nail angle machine and frame strip, which is applied in nailing tools, nailing staple tools, frames, etc., can solve the problems of poor comfort, unsuitable adjustment of the height of the air nail gun, affecting the nail angle efficiency, etc., and achieves efficiency improvement, Improve work efficiency and convenience, and apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings.

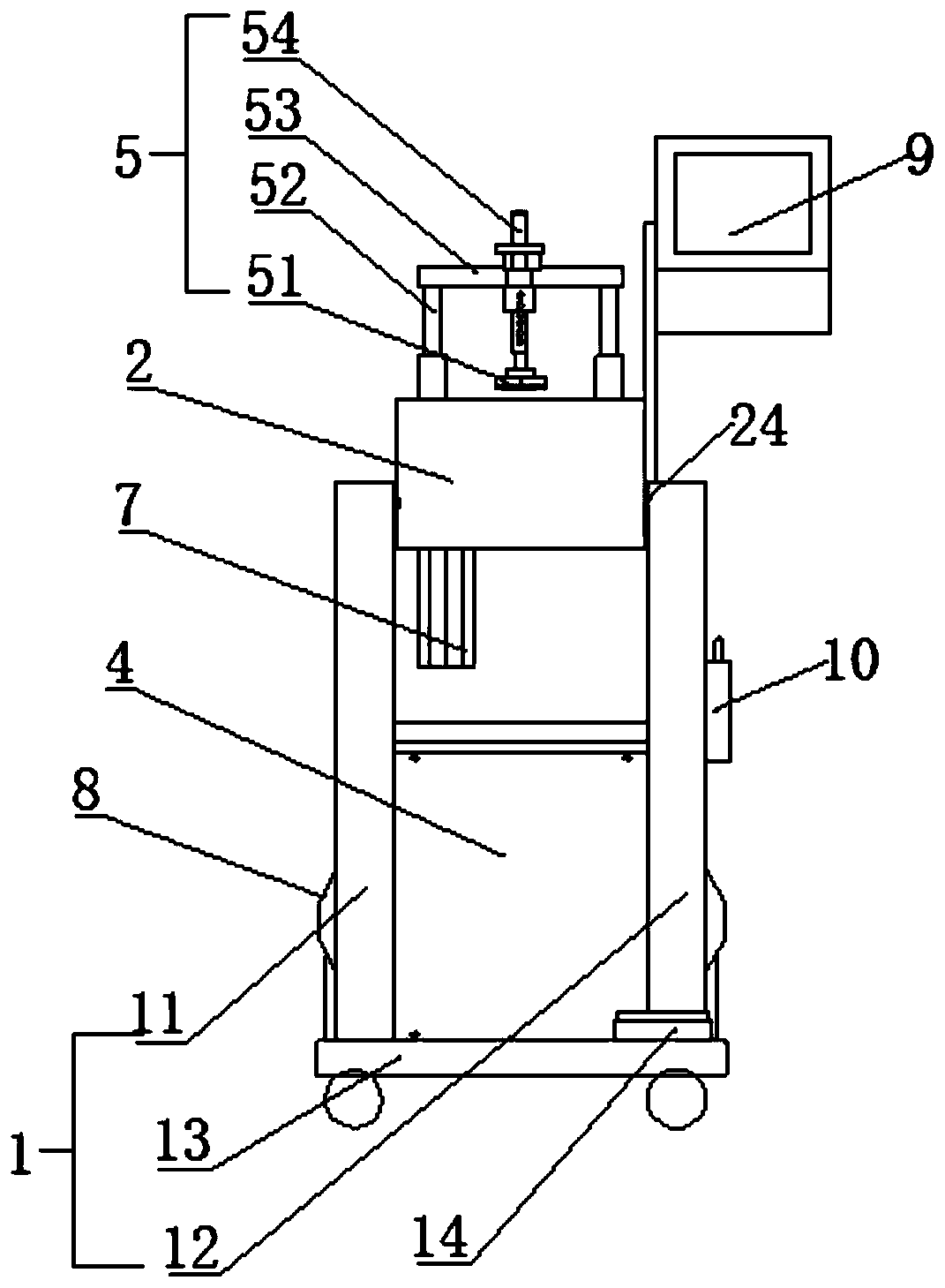

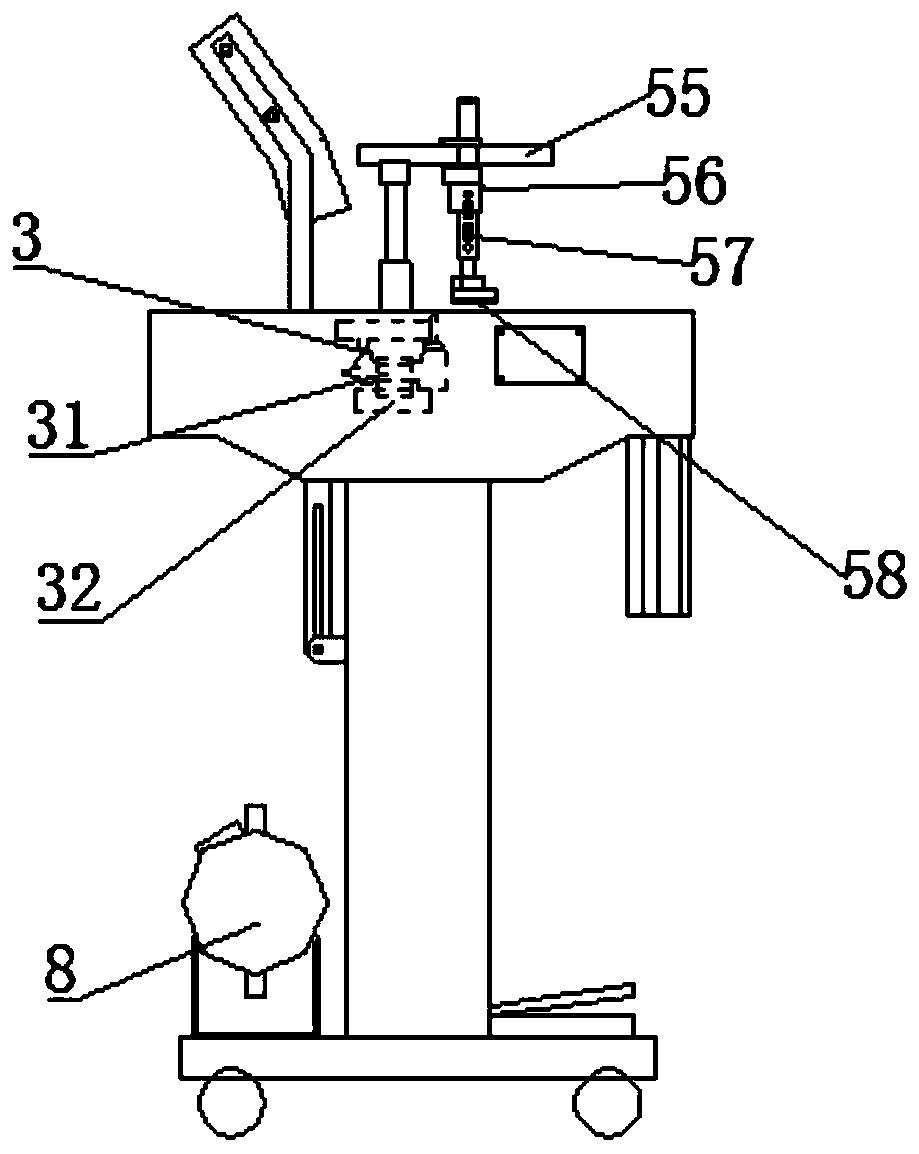

[0035] Such as Figure 1~3 shown (with image 3 In order to facilitate the identification of the figure number, the connecting beam and the column are not shown), a frame nailing machine of the present invention includes a frame 1, a workbench 2, an air nail gun 3 and a control system 4, and the frame 1 includes a left Column 11, right column 12 and base frame 13; Described workbench 2 is arranged between left column 11 and right column 12, and described workbench 2 can move up and down along left column 11 and right column 12;

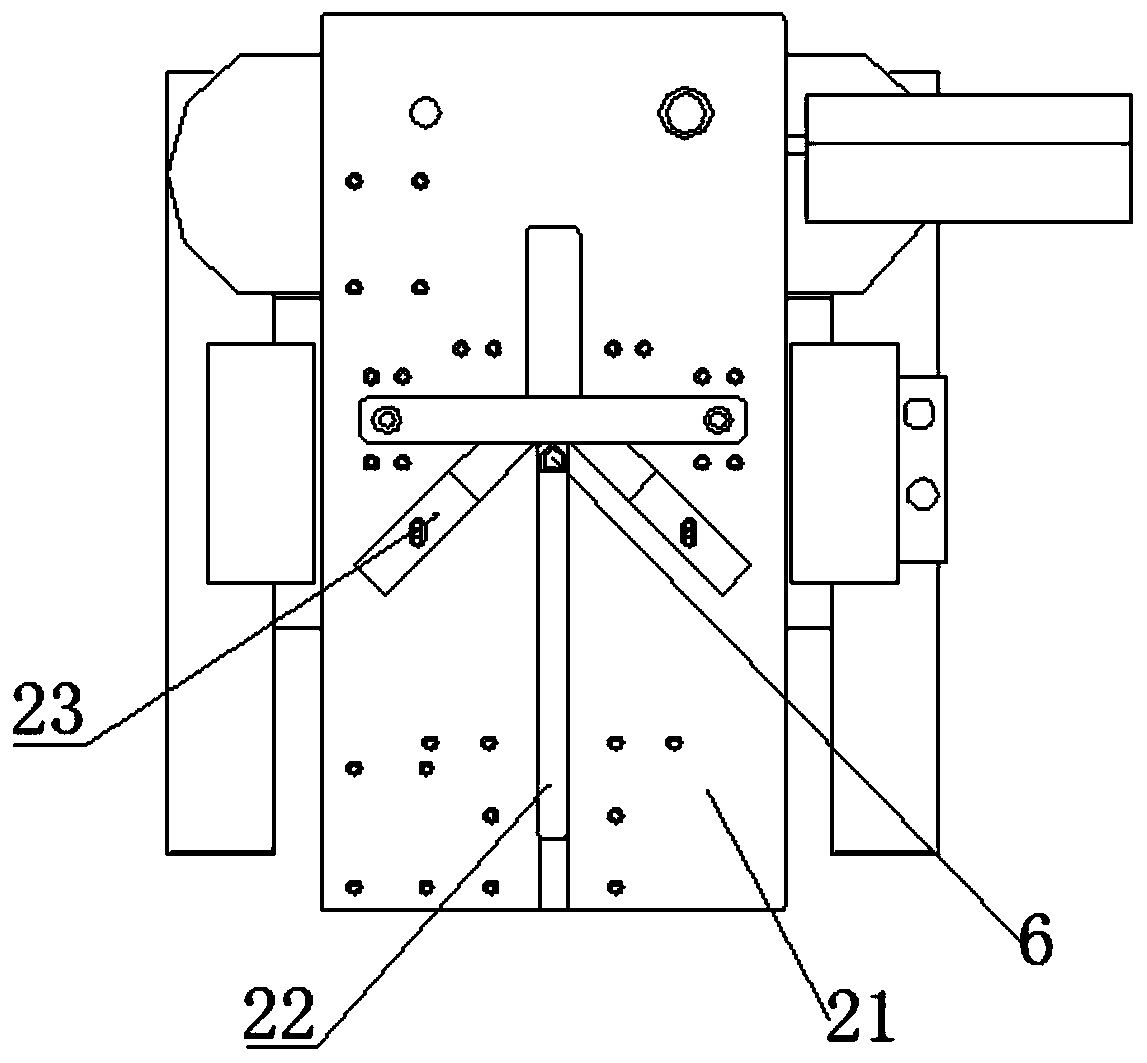

[0036] The workbench 2 is provided with a platen 21, and the middle part of the platen 21 is provided with a strip-shaped nail outlet 22 for brad nails to freely enter and exit. The nail outlet 22 is provided with a detachable positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com