Novel corrugating machine

A corrugating machine, a new type of technology, applied in the direction of mechanical processing/deformation, can solve the problems of inability to adjust the corrugating roller, affecting the processing efficiency, poor flexibility of the device, etc., to avoid waste, improve processing efficiency, and use Safe and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

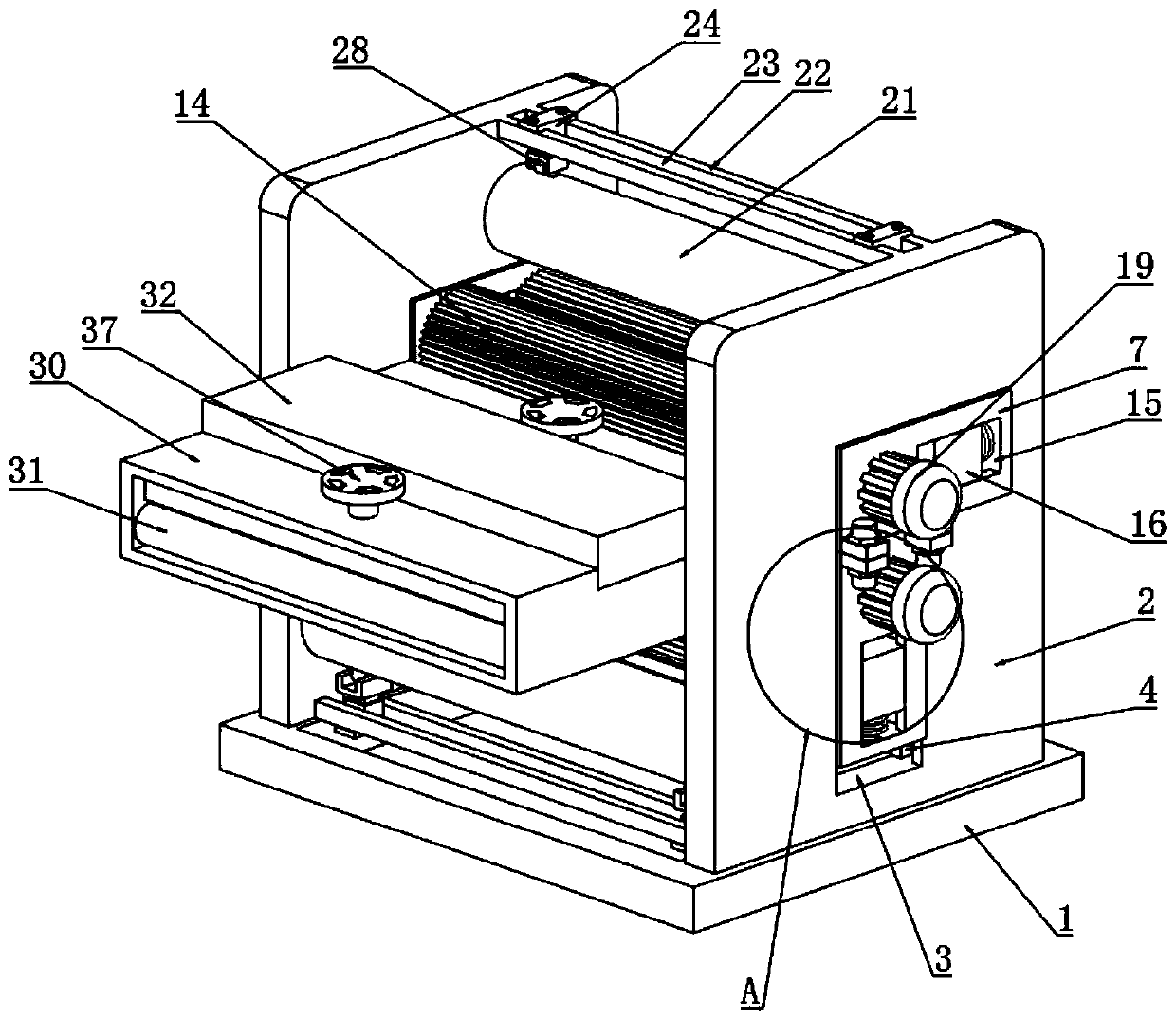

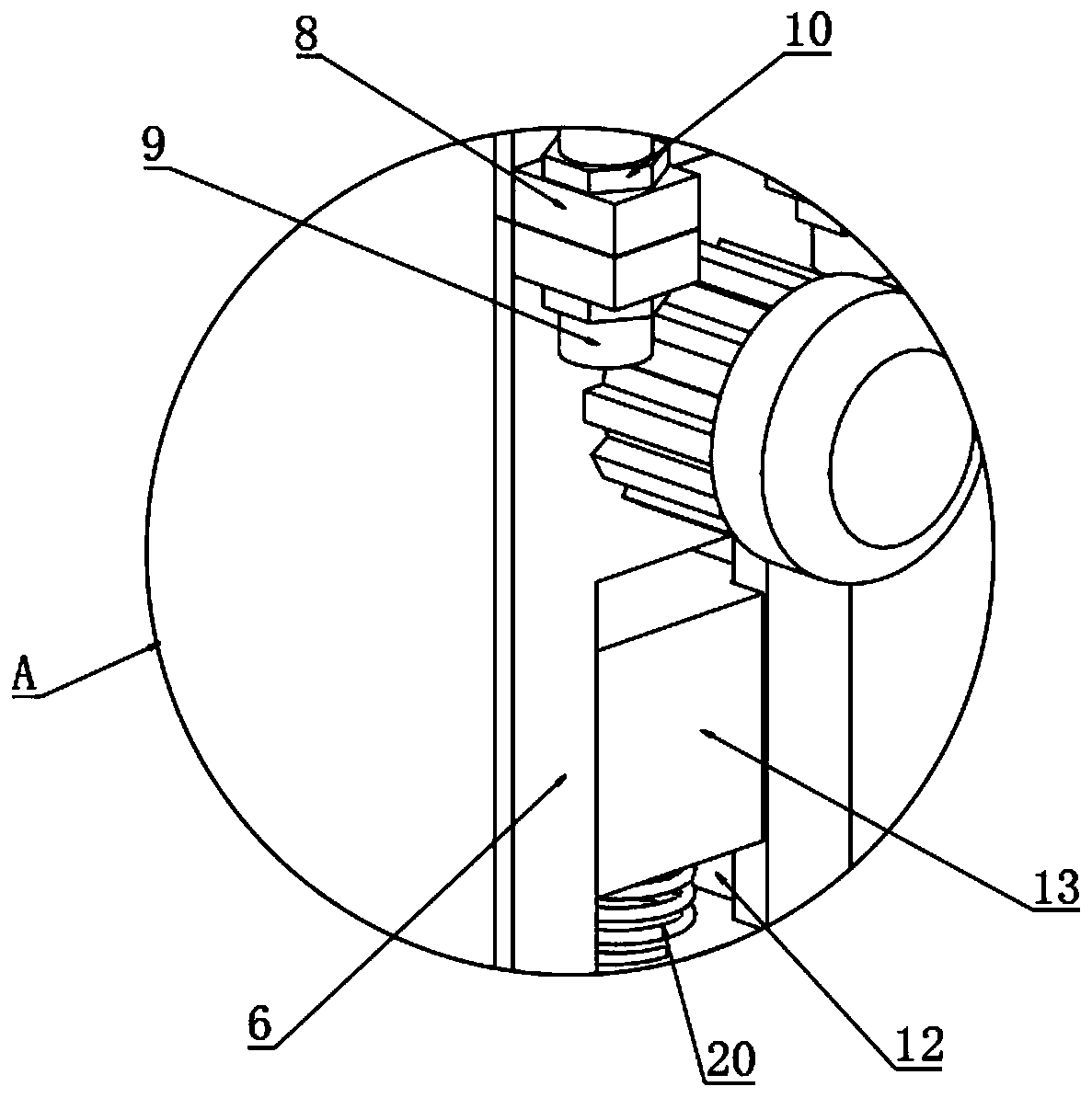

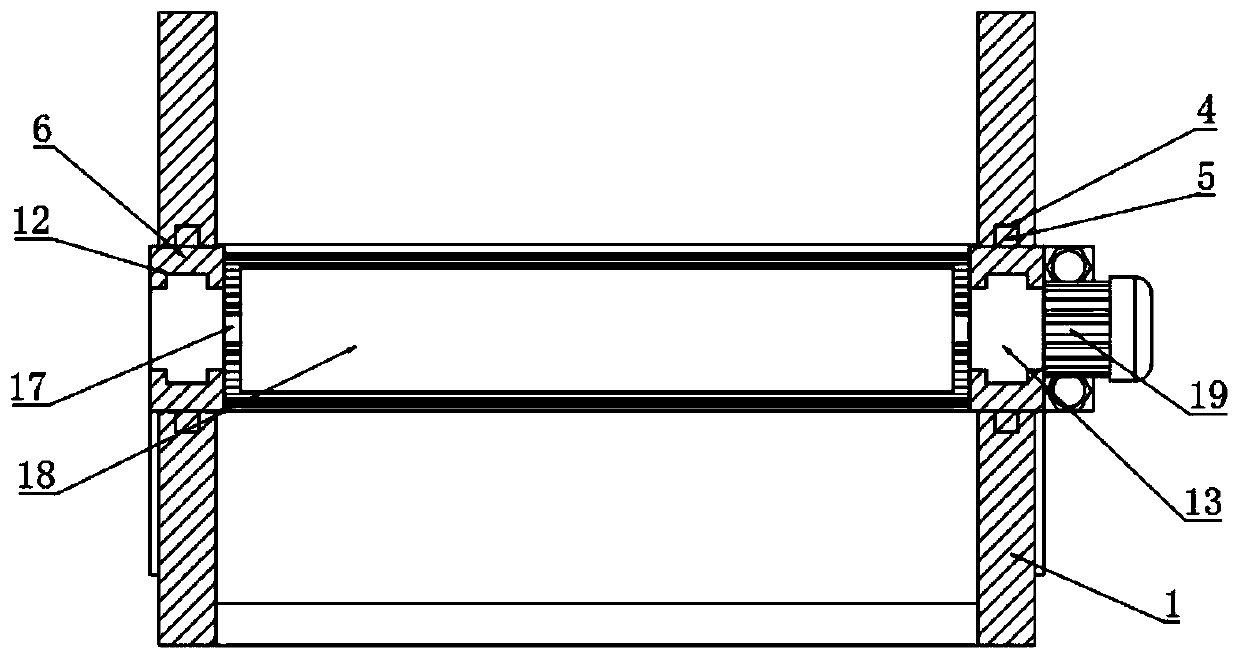

[0031] Example: such as Figure 1-6 As shown, the present invention provides a technical solution, a new type of corrugating machine, including a bottom frame 1, the top of the bottom frame 1 is symmetrically fixedly connected with a bracket 2, and the middle positions of the two brackets 2 are provided with a rectangular groove 3, and the rectangular groove 3 The first chute 4 is symmetrically opened inside, and the inside of the first chute 4 is slidingly connected with a slider 5, and the adjacent ends of the two sliders 5 are fixedly connected to the movable plate 6, and the middle positions of the two brackets 2 correspond to the top of the movable plate 6 Position place is fixedly connected with fixed plate 7, in order to ensure the consistency of movable plate 6 and fixed plate 7, the length, width and height of movable plate 6 are equal to the length, width and height of fixed plate 7, movable plate 6 and fixed plate 7 It is distributed in an L shape, the top of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com