Novel steel character code and character box structure for steel code typesetting

A technology of steel character codes and character code boxes, which is applied in the field of steel code automatic typesetting, which can solve the problems of inconvenient typesetting and clamping of character codes, deformation or damage of character codes, and empty characters, so as to reduce the auxiliary time of typesetting and improve the use of Lifespan, the effect of reducing the elapsed time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

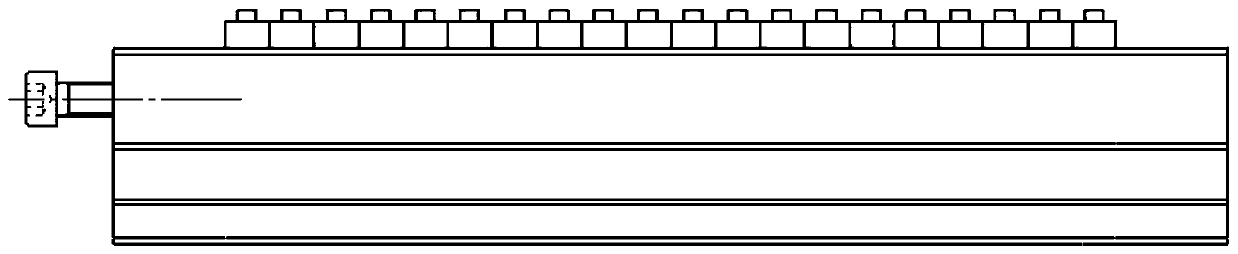

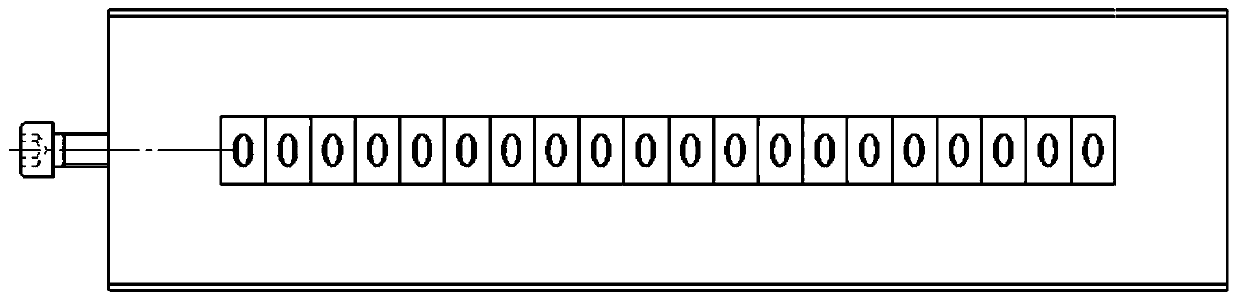

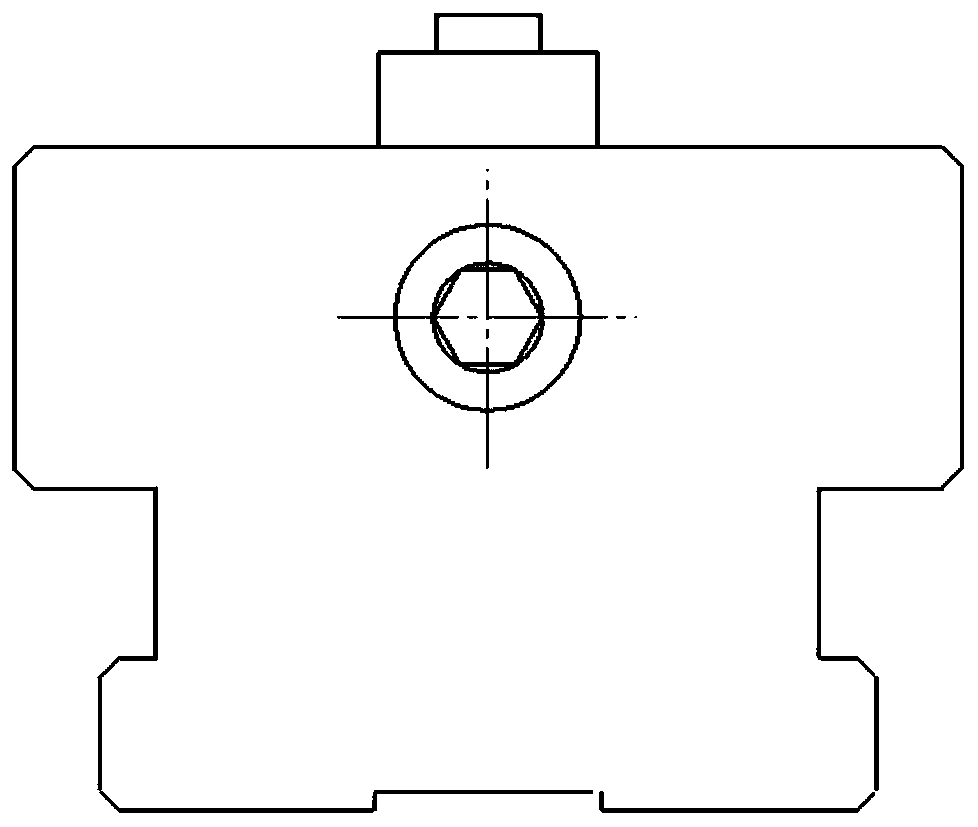

[0036] by Figure 21 , Figure 23 , Figure 24 , Figure 25 As an example, a new type of steel character code and character code box structure for steel code sorting is characterized in that it consists of a left pressing plate 1, a new type of steel character code 2, a fixed limit plate 3, a movable limit plate 4, and a right Press plate 5, right press plate pin shaft 6, left press plate pin shaft 7, fixed base 8, and movable base 9. Left press plate 1 and right press plate 5 are respectively positioned with fixed base 8 by two positioning pins, and are pressed by screws. Left press plate 1 and the pin shaft 7 of the left pressure plate, and between the right pressure plate 5 and the pin shaft 6 of the right pressure plate are all interference fits, ensuring that the pin shaft 7 of the left pressure plate is coaxial with the pin shaft 6 of the right pressure plate, and there are shaft holes on both sides of the movable base 9, respectively The left and right pressure plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com