Method for fabricating nano long fiber

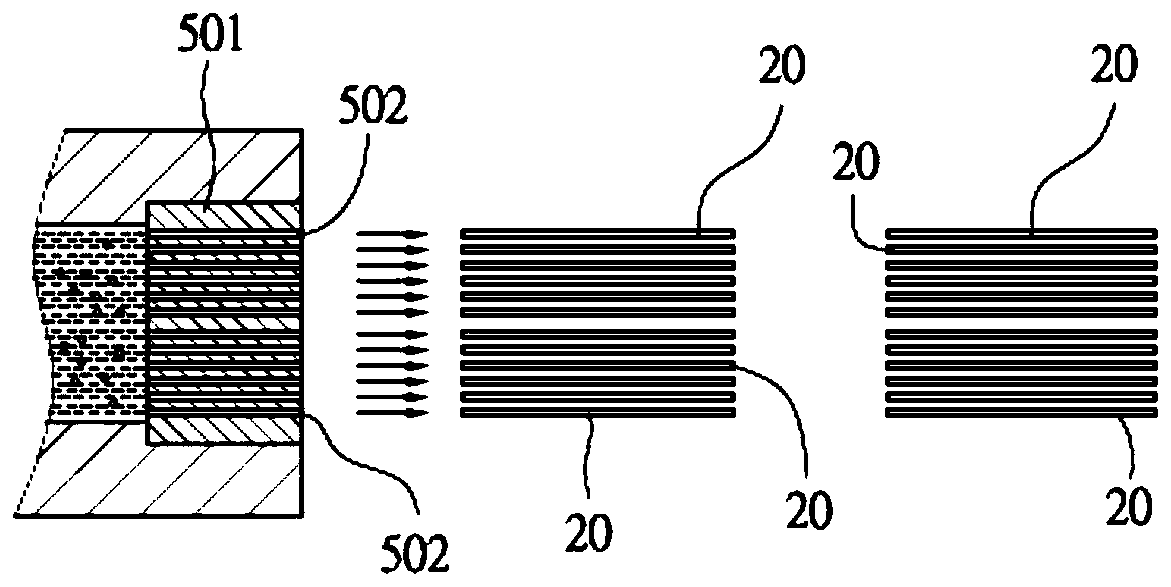

A production method and long fiber technology, applied in rayon manufacturing, fiber chemical characteristics, single-component polyester rayon, etc., can solve the problem of blocking the pressing fiber hole 502

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a further understanding of the present invention, the following examples are listed for illustration.

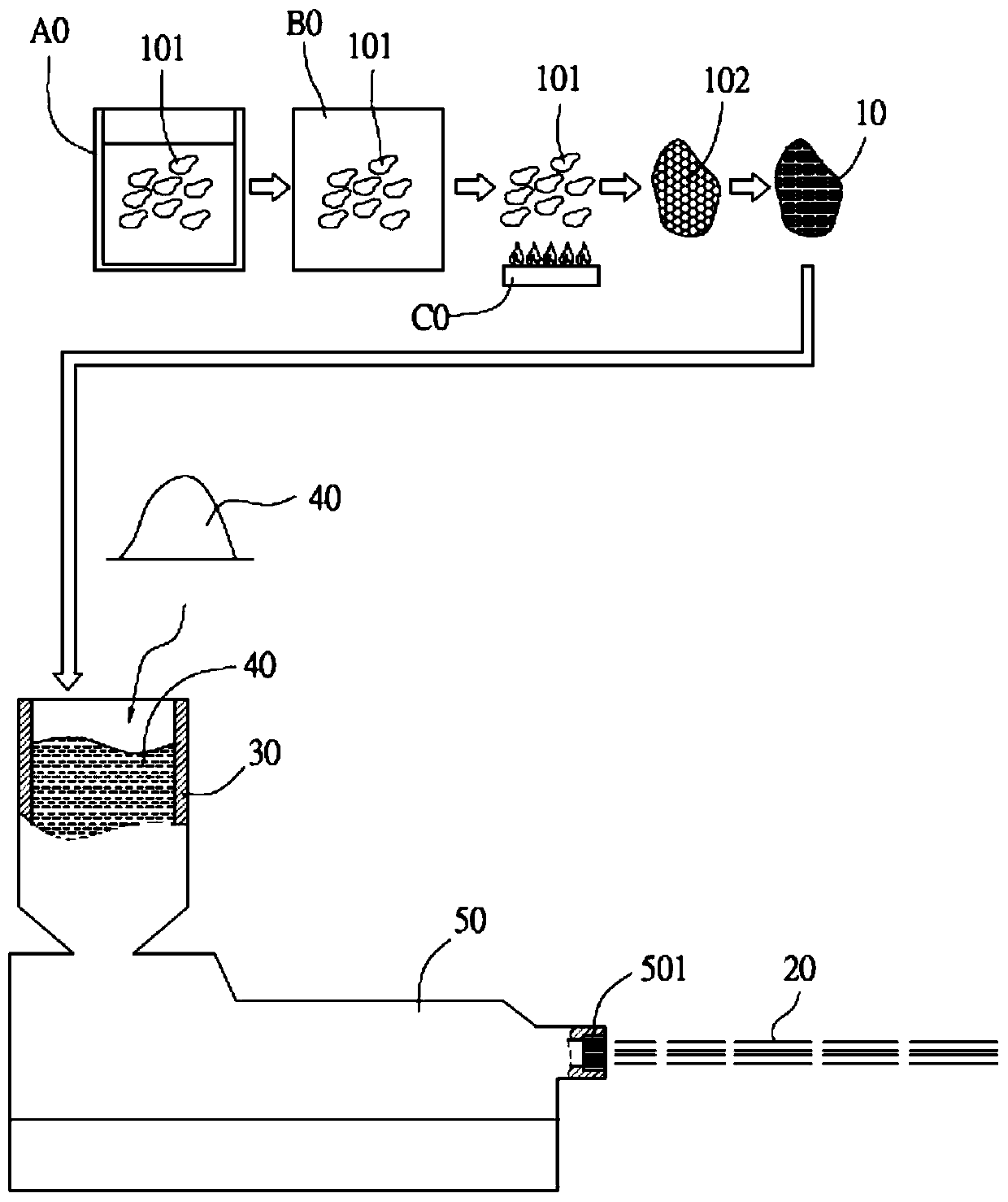

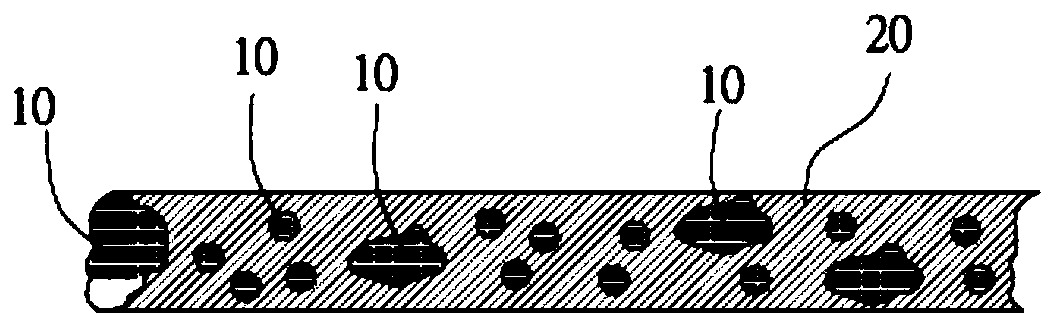

[0033] The present invention provides a method for manufacturing nano-long fibers, wherein the preparation and selection of the nano-long fibers 1 at least include: oyster shells 11, dispersants 12, graft copolymers 13, polyester 14 for the first long fibers Polyester 15 is used for the second long fiber, and the mixing tank 2 and the long fiber making machine 3; and the manufacturing steps of the nano long fiber 1 at least include: first cleaning the surface of the oyster shell 11 clean, the cleaned The oyster shell 11 is dried B again, and then the oyster shell 11 is calcined C to form oyster shell ash 111, and then the oyster shell ash 111 is ground into nano-oyster shell powder 112, and the surface of the nano-oyster shell powder 112 is covered with a layer of the dispersed agent 12, and the surface of the nano oyster shell powder 112 that already...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com