Underground oil-water separator

An oil-water separator and oil-water separation technology, which is applied in wellbore/well parts, production fluid, earthwork drilling and production, etc., can solve the problems of long mechanical parts and high maintenance costs, and achieve reduced oil production frequency, no energy consumption, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

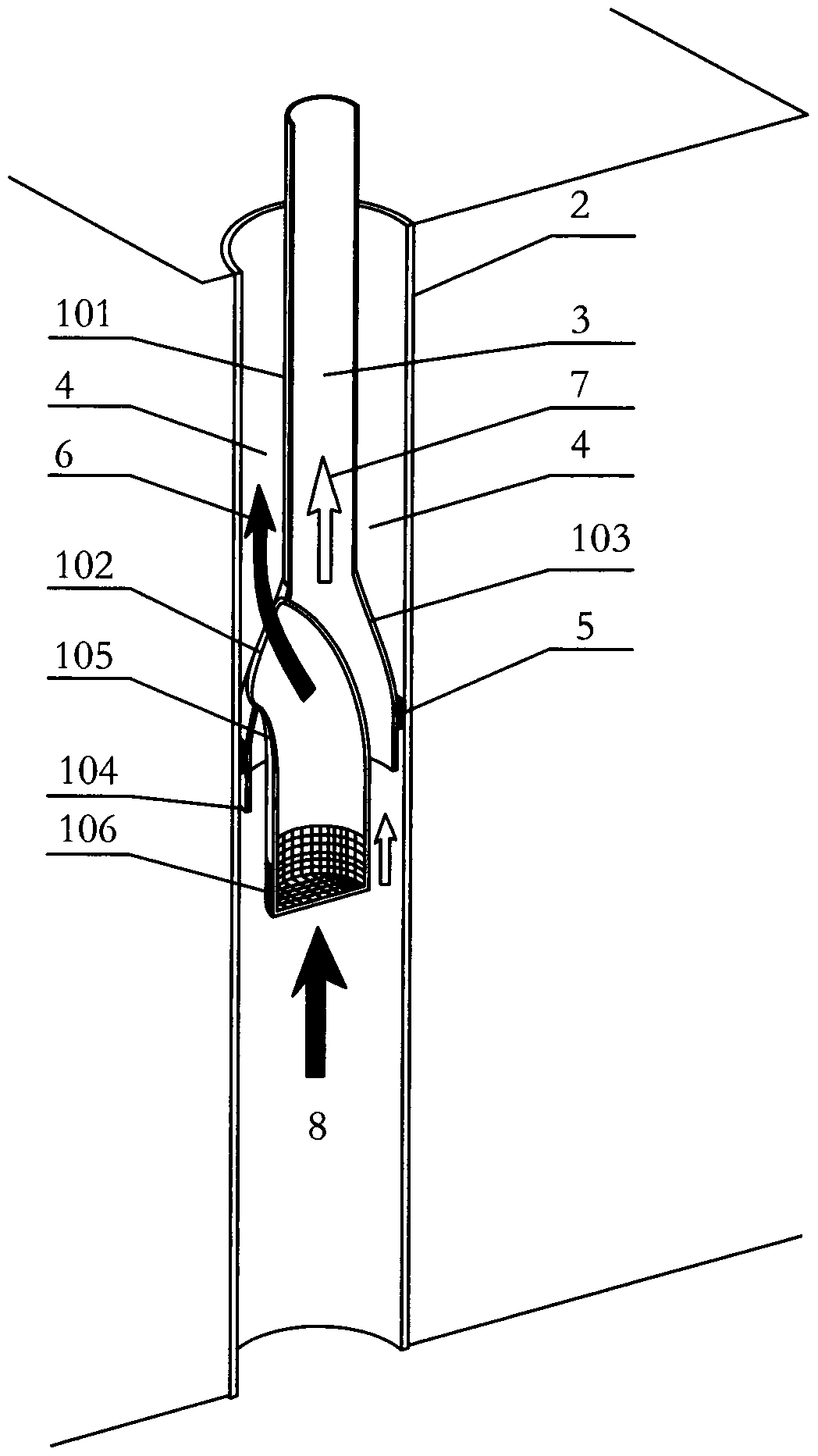

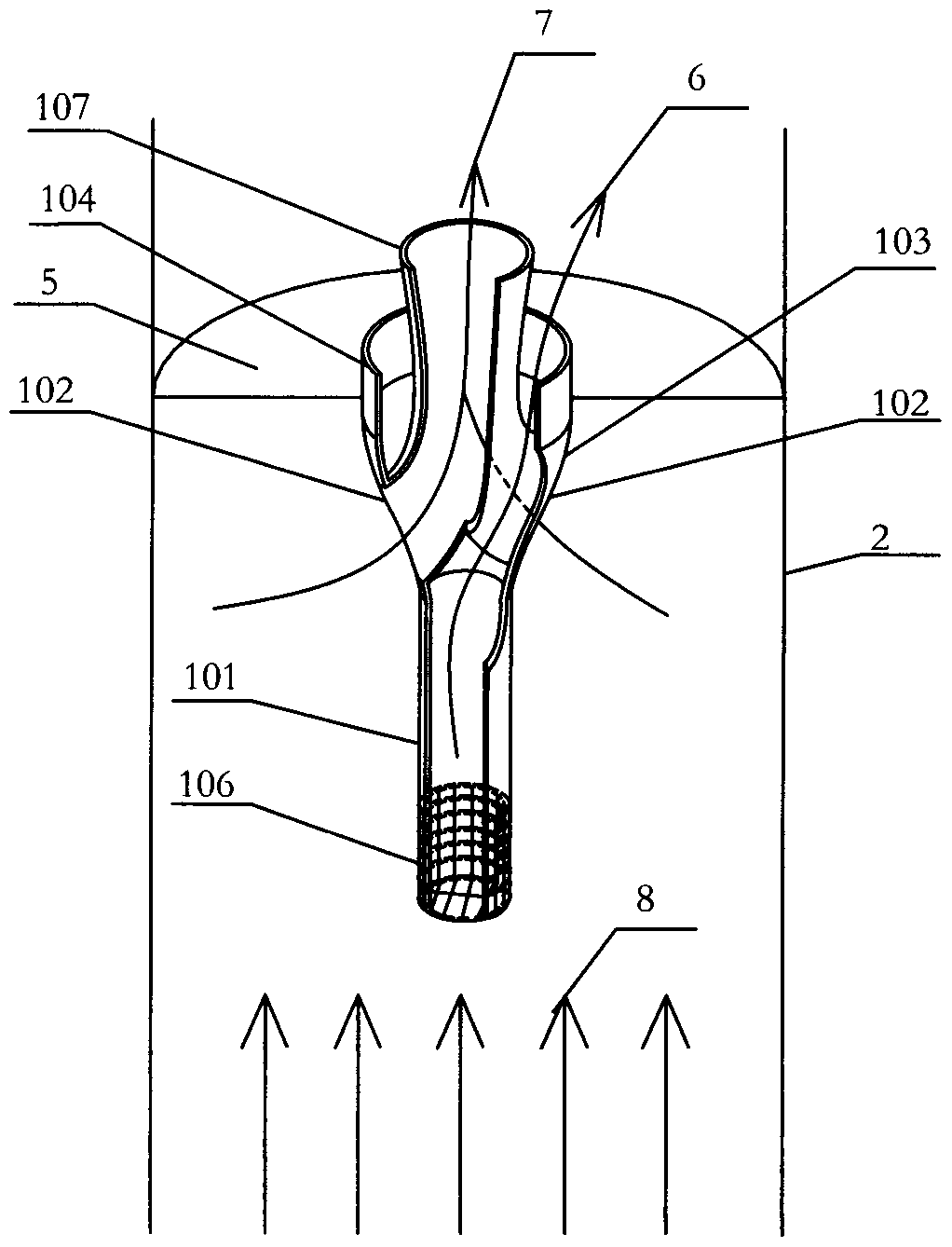

[0013] The downhole oil-water separator provided by the present invention will be further explained in conjunction with the accompanying drawings and the existing oil production technology.

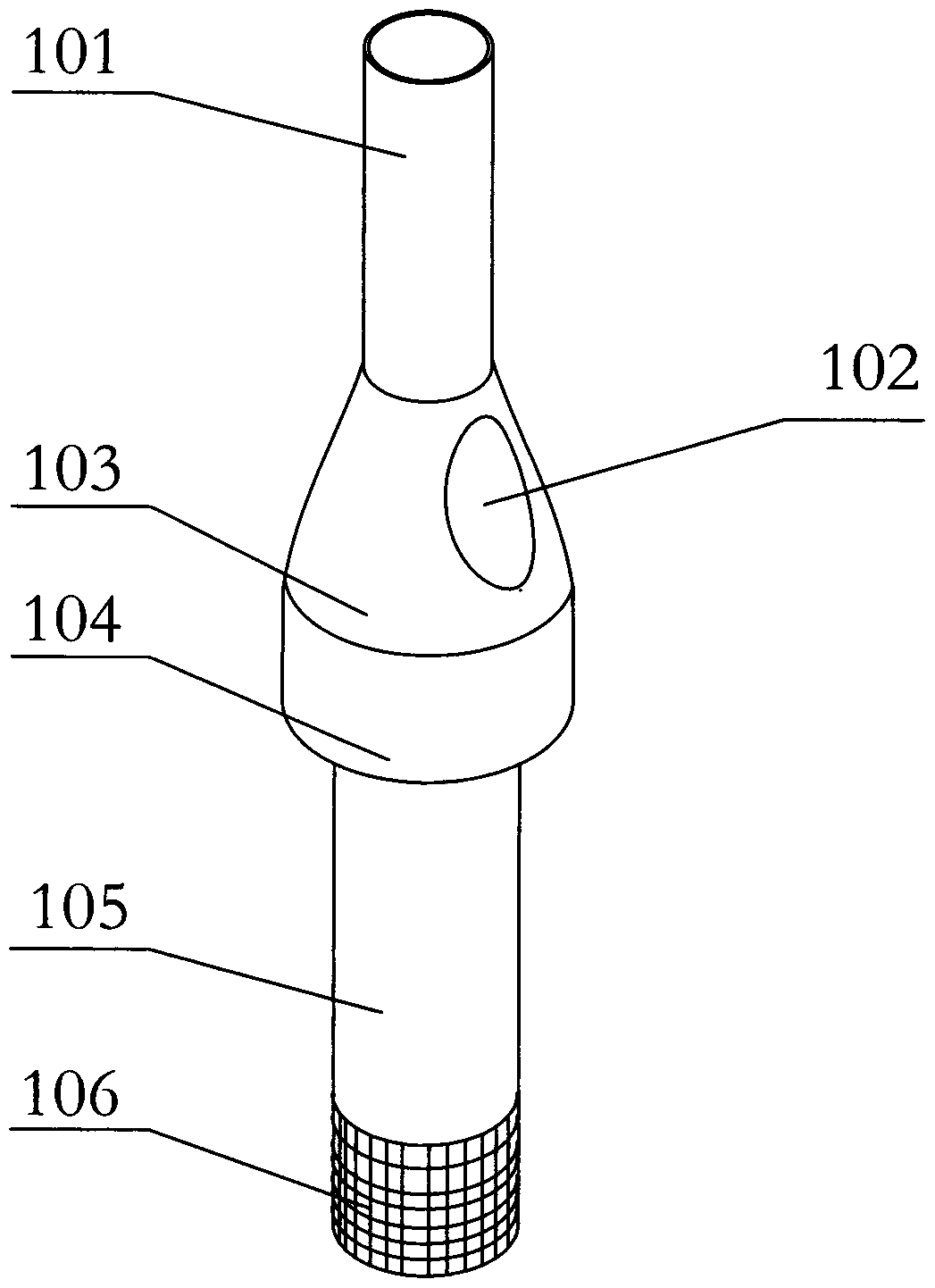

[0014] Such as figure 1 , figure 2 A downhole oil-water separator shown includes: a conical surface (103), a J-shaped elbow (105); the upper end of the conical surface (103) is connected with a small opening (101), and its lower end is connected with a large opening (104); The conical surface (103) is also provided with a round hole (102); the J-shaped elbow (105) is inverted, the upper end is connected to the round hole (102), and the oil-water separation membrane (106) is connected to the lower end.

[0015] The oil-water separation membrane (106) can be a net coated with an oleophobic material on the outer surface, or it can be other new invention materials; the waste water can pass through smoothly, and the crude oil agglomerate is due to the repulsion between the molecules of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com