Instrument comprehensive information manager for substation

A technology of comprehensive information and manager, applied in the field of comprehensive information manager of substation instruments, can solve the problems of untimely data, low work efficiency, inaccurate data, etc., and achieve the effect of convenient real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

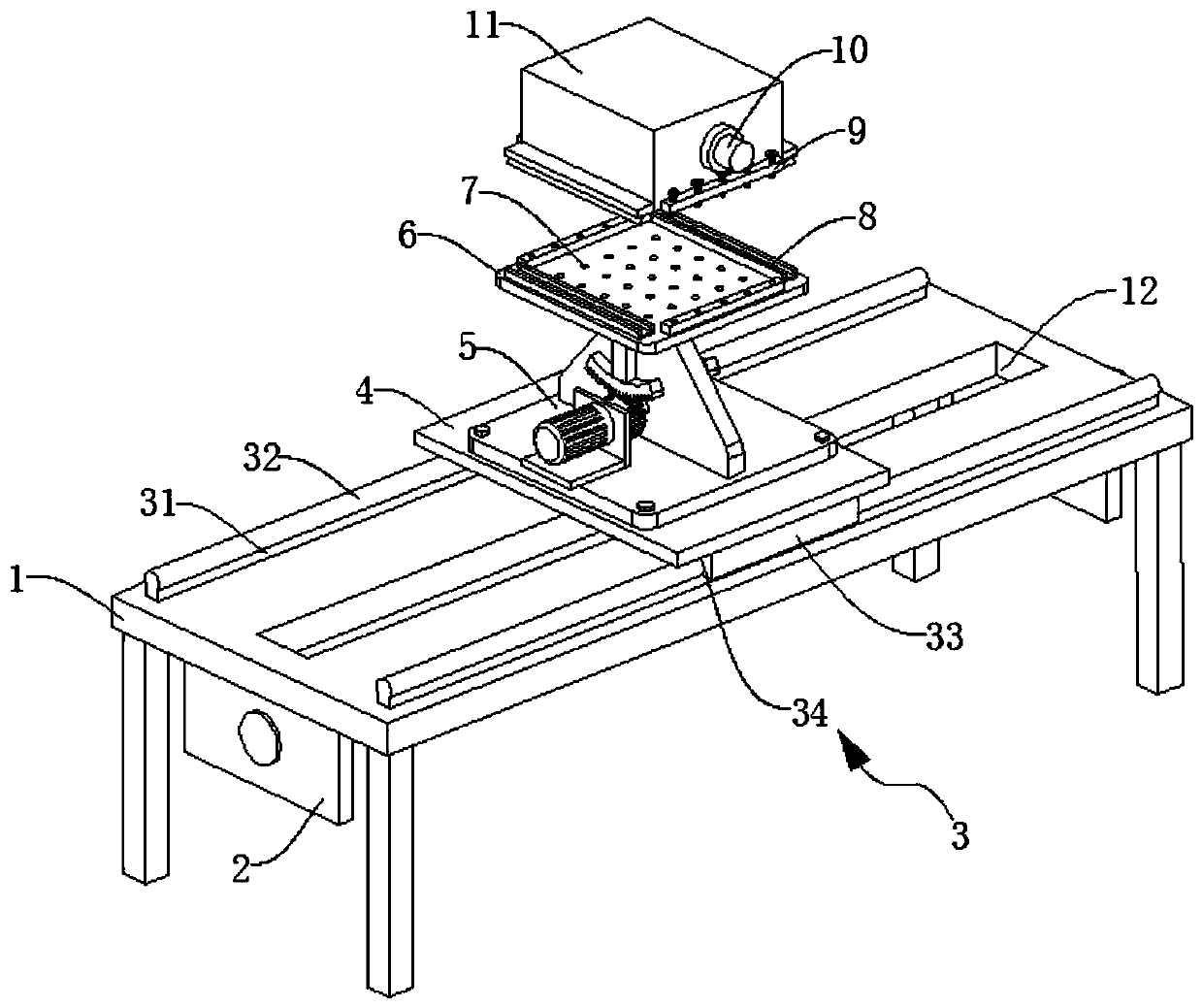

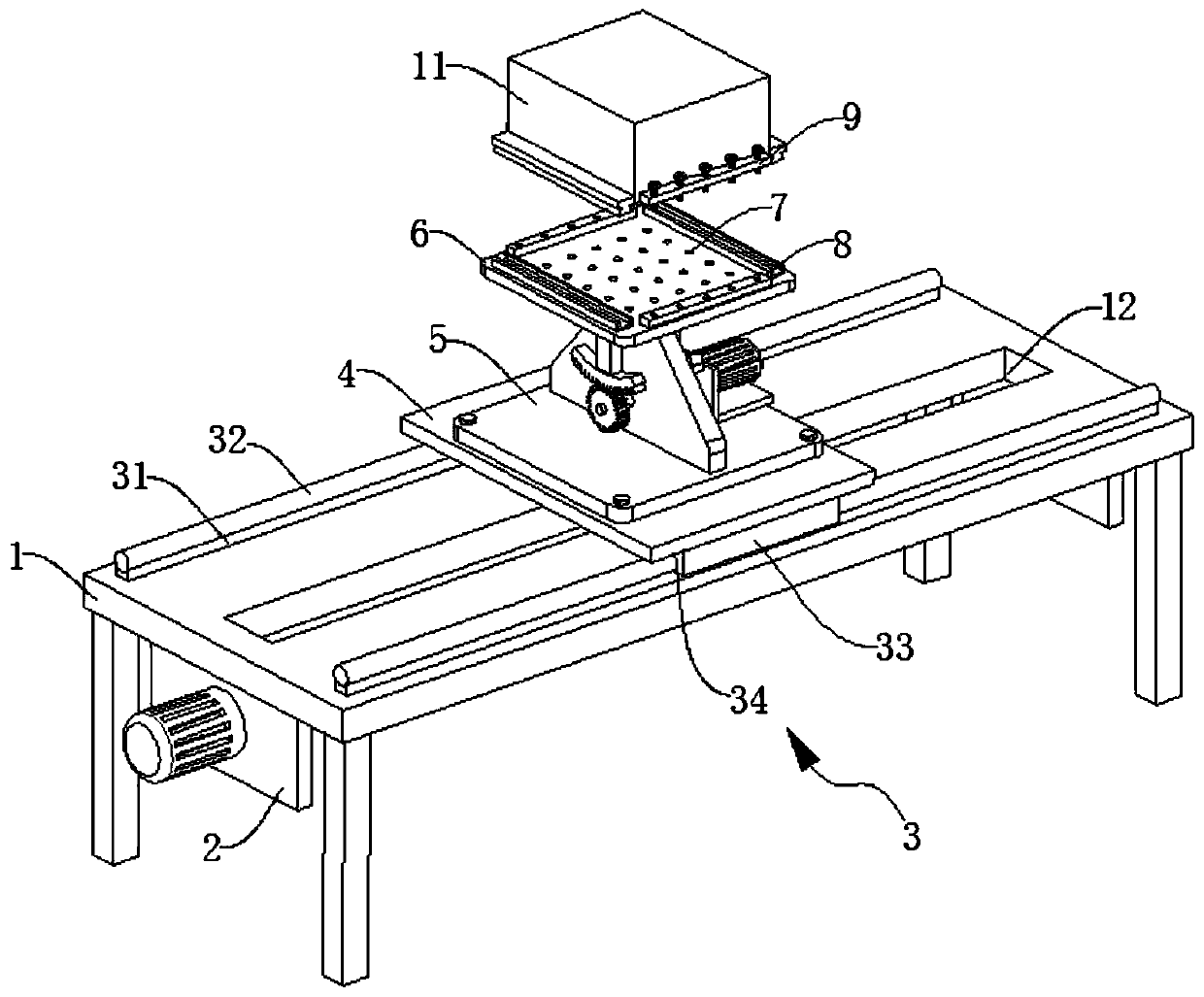

[0022] refer to Figure 1-4 , an instrument integrated information manager for a substation, comprising a chassis 1, the bottom surface of the chassis 1 is fixedly connected with a horizontal position adjustment mechanism 2, the middle part of the upper surface of the chassis 1 is provided with a port 12, and the horizontal position adjustment mechanism The upper end of 2 runs through the opening 12 and is fixedly connected with a base plate 4. A sliding guide mechanism 3 is respectively arranged between the two sides of the lower surface of the base plate 4 and the two sides of the upper surface of the chassis 1, and the middle part of the upper surface of the base plate 4 is fixedly connected with a An angle adjustment mechanism 5, the upper end of the angle adjustment mechanism 5 is fixedly connected with a rotating plate 6, and both sides of the upper surface of the rotating plate 6 are respectively provided with a mounting mechanism 9, and the upper surface of the rotating...

Embodiment 2

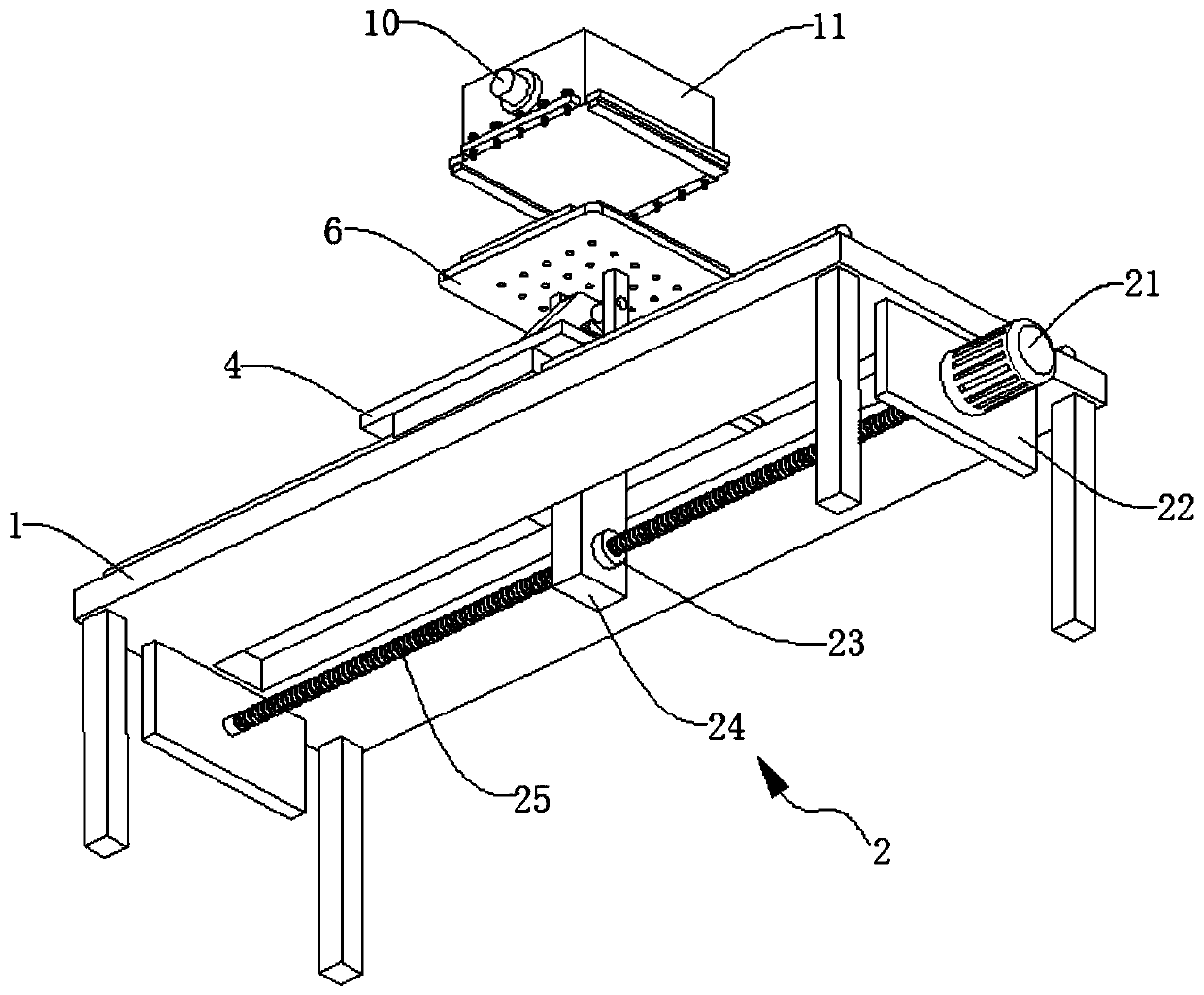

[0025] refer to Figure 1-3 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the horizontal position adjustment mechanism 2 includes two mounting plates 22 and a moving block 24, and the two mounting plates 22 are respectively fixedly connected under the chassis 1 On both sides of the bottom surface, the moving block 24 is fixedly connected to the middle position of the bottom surface of the bottom plate 4, and a screw mandrel 25 is rotatably connected between the two mounting plates 22 through bearings, and the outer thread of the screw mandrel 25 is connected with a threaded sleeve 23, And the lower end of the moving block 24 passes through the port 12 and is fixedly connected to the outside of the threaded sleeve 23, the middle part of one side of the mounting plate 22 is fixedly connected with the second motor 21, and one end of the screw rod 25 penetrates the mounting plate 22 and is fixedly connected On the output shaft...

Embodiment 3

[0027] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the sliding guide mechanism 3 includes a long rod 31 and a first slider 33, the long rod 31 is fixedly connected to one side of the upper surface of the chassis 1, and the second A slide block 33 is fixedly connected to one side of the lower surface of the base plate 4 , the upper end of the long rod 31 is fixedly connected with a slide rail 32 , and the middle part of the lower surface of the first slide block 33 is provided with a first chute 34 , and the first chute 34 Slidably arranged on the outside of the slide rail 32, the first slide groove 34 is an arc-shaped structure, and the arc of the first slide groove 34 is greater than 180 degrees. Through this design, in the process of adjusting the horizontal position, the first slide block 33 will slide on the slide rail 32 and along its axial direction through the first sliding groove 34, thereby ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com