Disc type motor rotor disc vertical de-weight dynamic balancing method and equipment

A disc motor and balancing equipment technology, which is used in static/dynamic balance testing, machine/structural component testing, and measuring devices, etc., can solve the problem that the outer diameter of the disc motor rotor is large and the test device cannot meet the operational requirements. , easy to cause danger and other problems, to achieve the effect of eliminating the influence of shaft suction, convenient installation and detection, and convenient operation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings and specific embodiments.

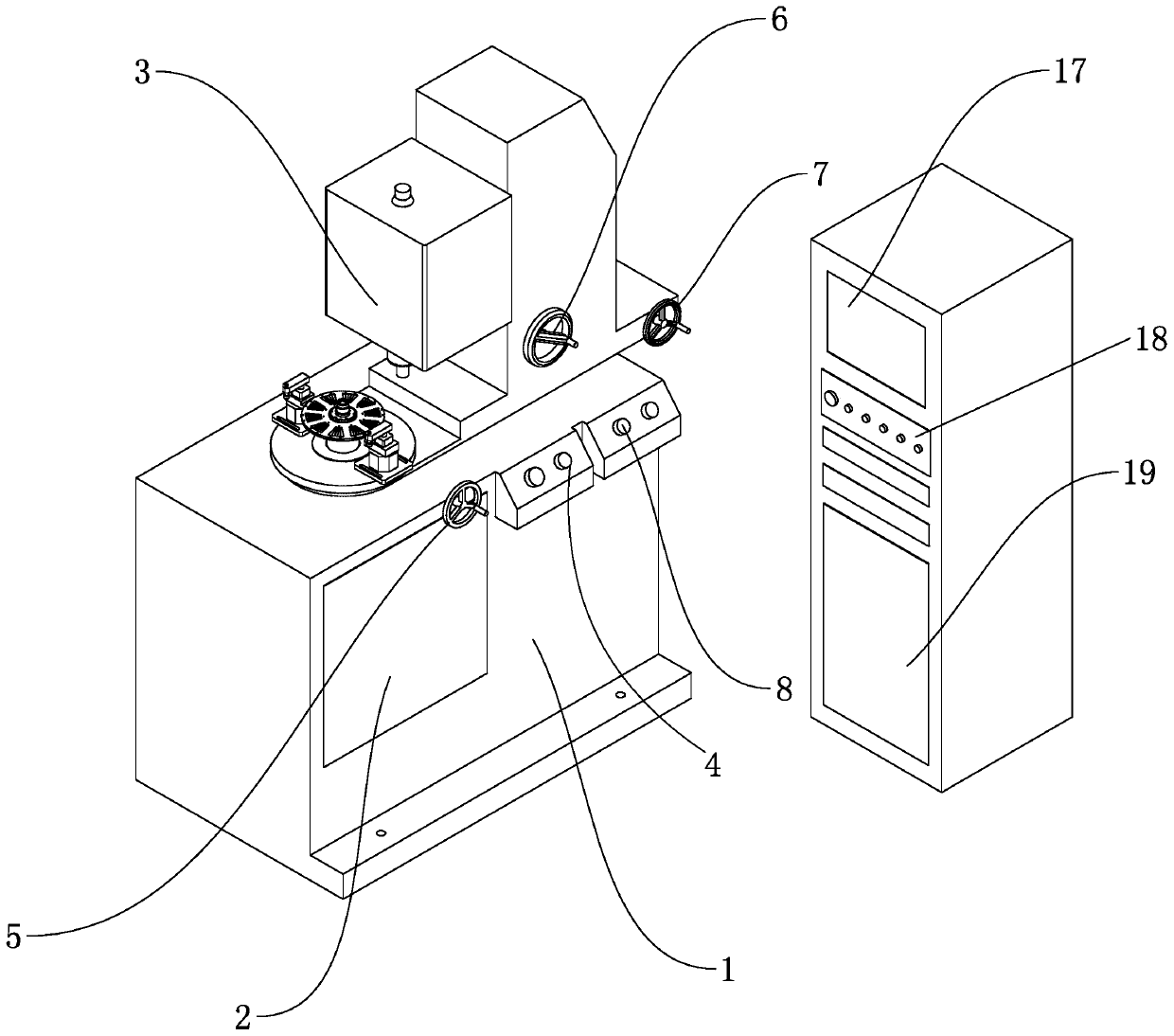

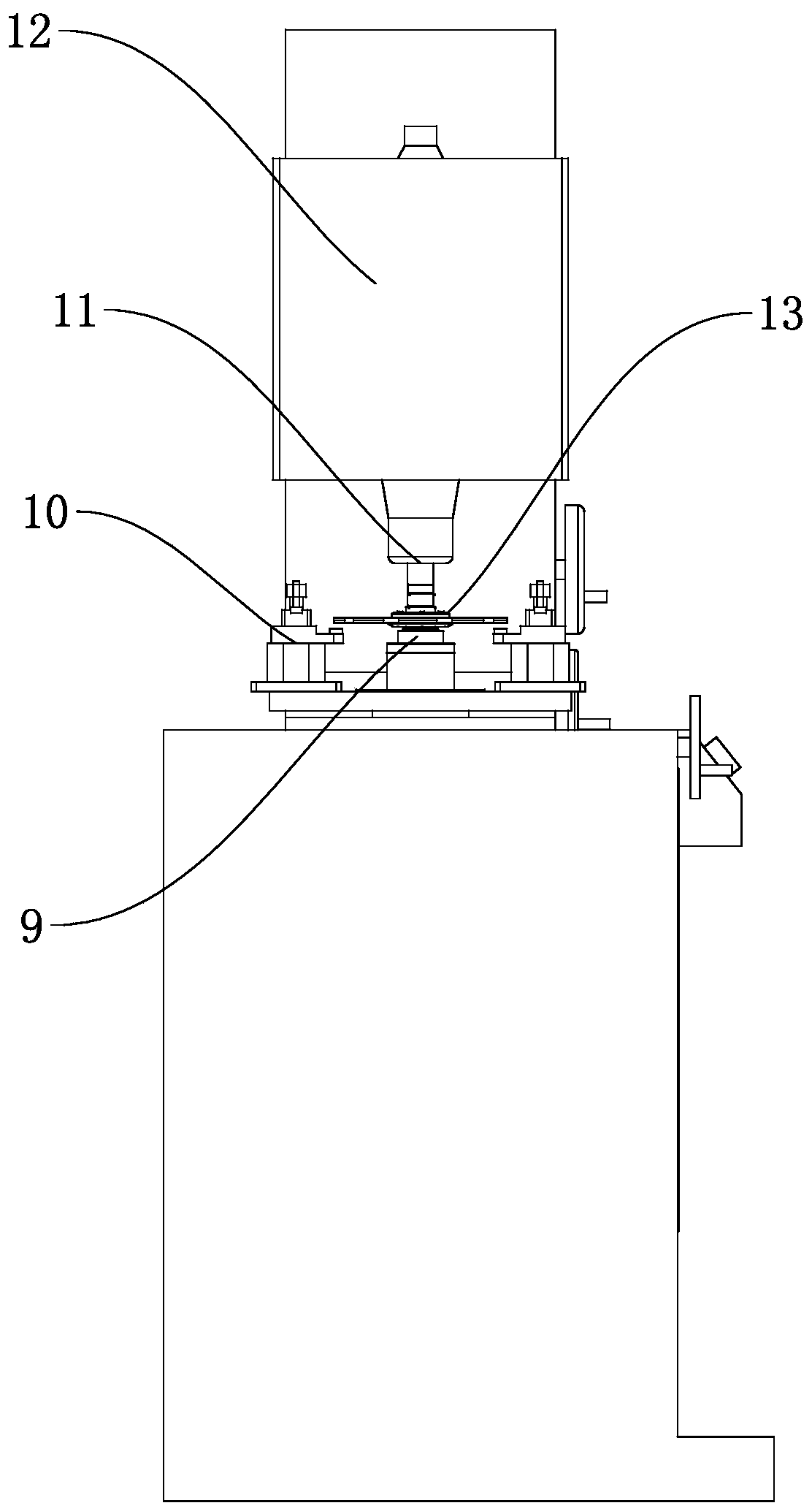

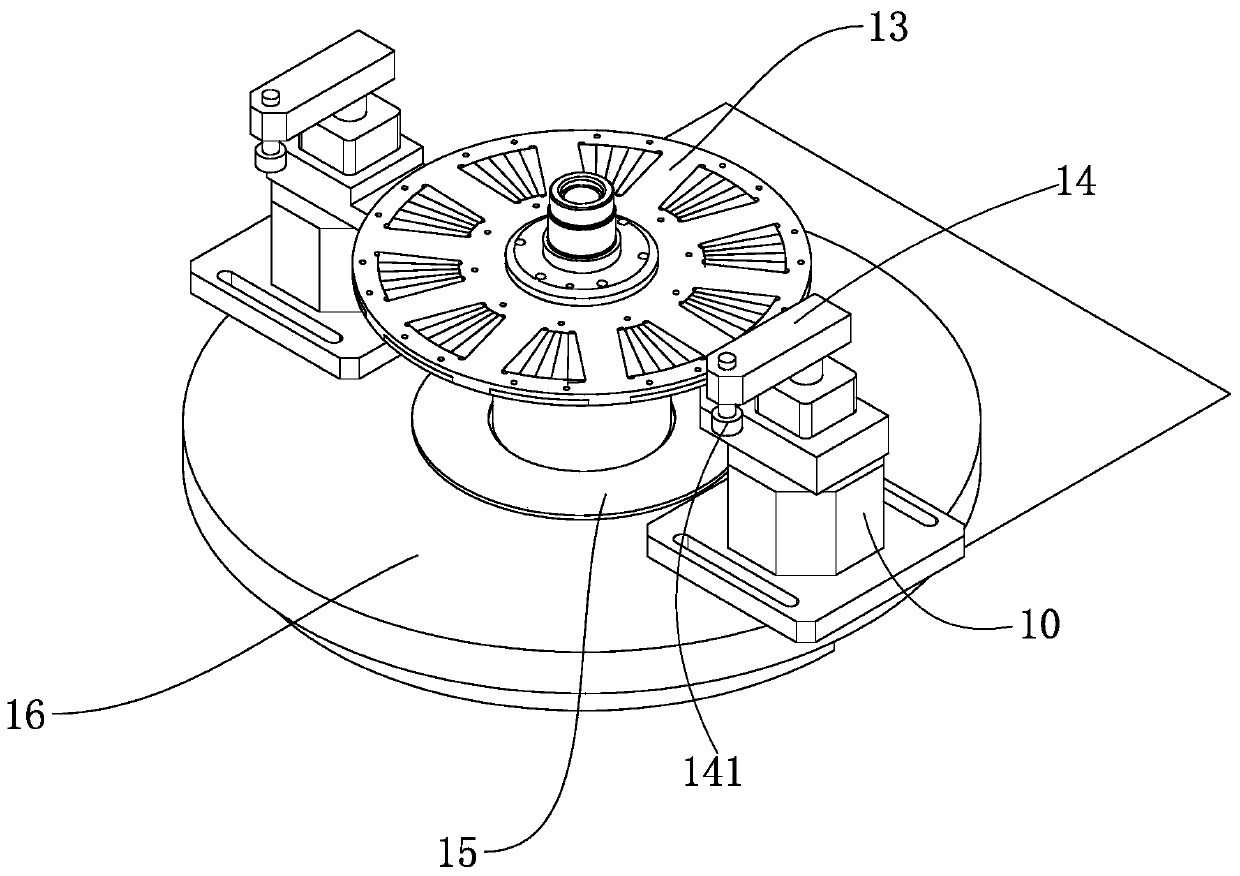

[0031] Such as Figure 1 to Figure 4 The illustrated embodiment is a vertical weight-removing dynamic balancing device for a disc motor rotor disc, which is characterized in that it includes a dynamic balancing machine body 1, which adopts the model PHLD-35H. The main body 1 of the dynamic balancing machine is equipped with an electric control box 19, and the electric control box 19 is provided with a control button 18 and a dynamic balance result display 17. The upper side of the dynamic balancing machine body 1 is provided with a rotatable rotating table 16, and the rotating table 16 is equipped with a rotating hand wheel 5. The body 1 of the dynamic balancing machine electrically drives the rotating table 16 to rotate through the traditional transmission mechanism 2, which is well known to those skilled in the art. In order to save space, the specific form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com