Vacuum cleaner with power control in dependence on mode of operation of electrical brush

A technology for vacuum cleaners and control units, which is applied in the installation of vacuum cleaners, vacuum cleaner equipment, and electrical equipment, and can solve problems such as the complex speed of control units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

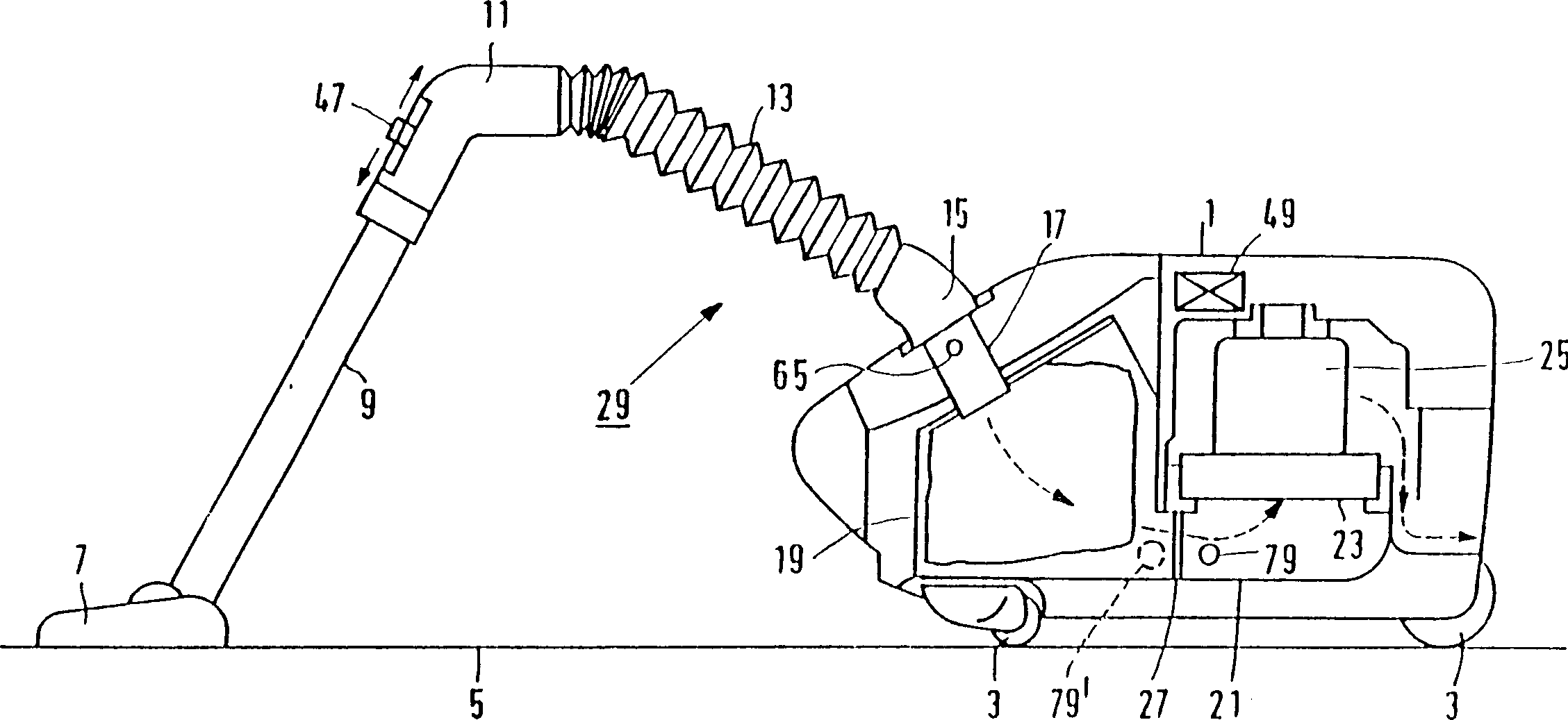

[0020] figure 1 The vacuum cleaner according to the invention shown comprises a housing 1 with a number of wheels 3, by means of which the housing 1 can be moved on the surface 5 to be cleaned. The vacuum cleaner also includes a suction member 7 which is rotatably connected with the suction pipe 9. The suction tube 9 is connected to the handle 11, and the handle 11 is connected to the housing 1 through a suction hose 13 and a connecting piece 15. The duct 17 in the housing 1 ends with a replaceable dust collector 19. Another duct 21 in the housing 1 connects the dust collector 19 with the suction unit 23, and the suction unit 23 can be driven by the first motor 25 in the housing 1. The filter 27 is on the other duct 21. During operation, the suction unit 23 generates a partial vacuum in the air path 29 composed of the suction member 7, the suction tube 9, the suction hose 13, the duct 17, the dust collector 19 and the other duct 21. An air flow is generated in the path 29, and du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com