Submarine cable

A cable and core wire technology, applied in the field of submarine cables, can solve the problems of limited compressive capacity, insufficient compressive capacity, and inability to transmit photoelectric signals, and achieve good compressive capacity, improved protection effect, and good protection effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

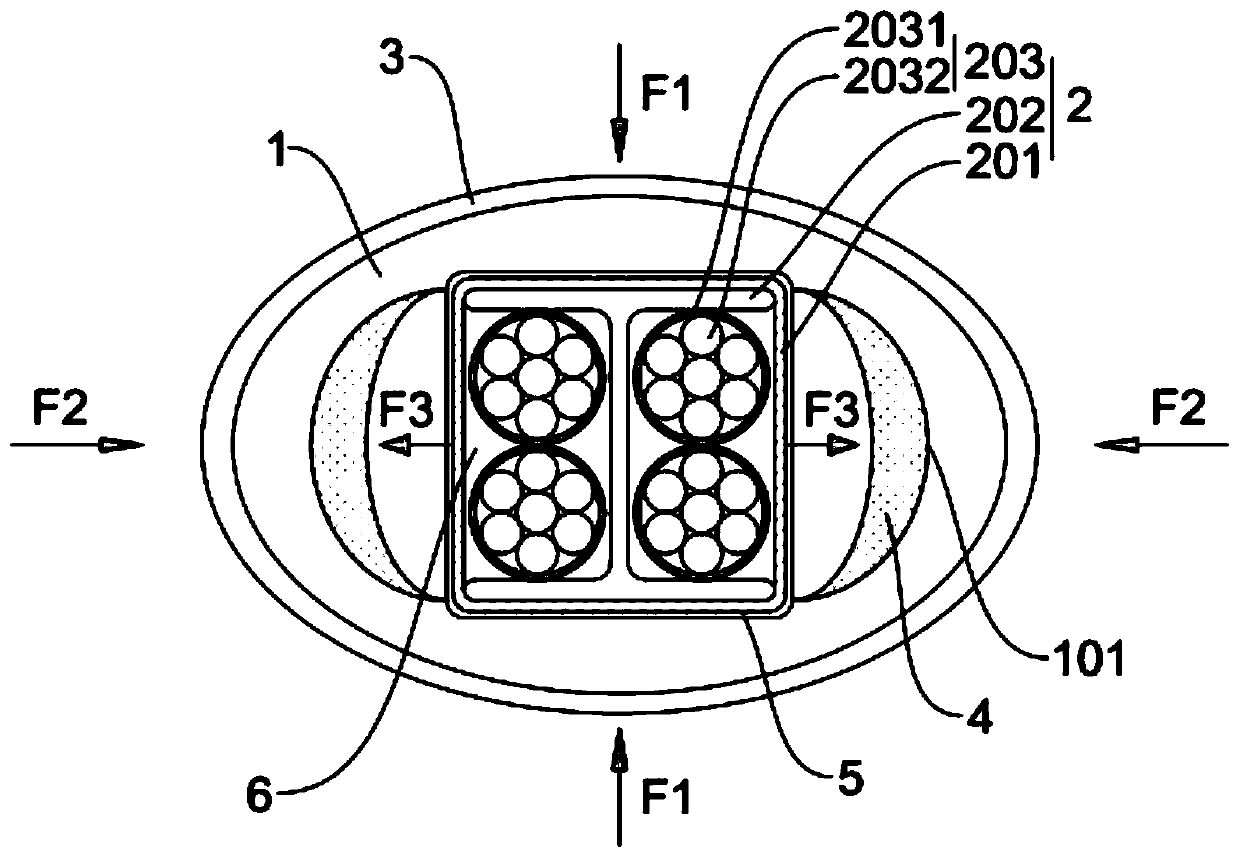

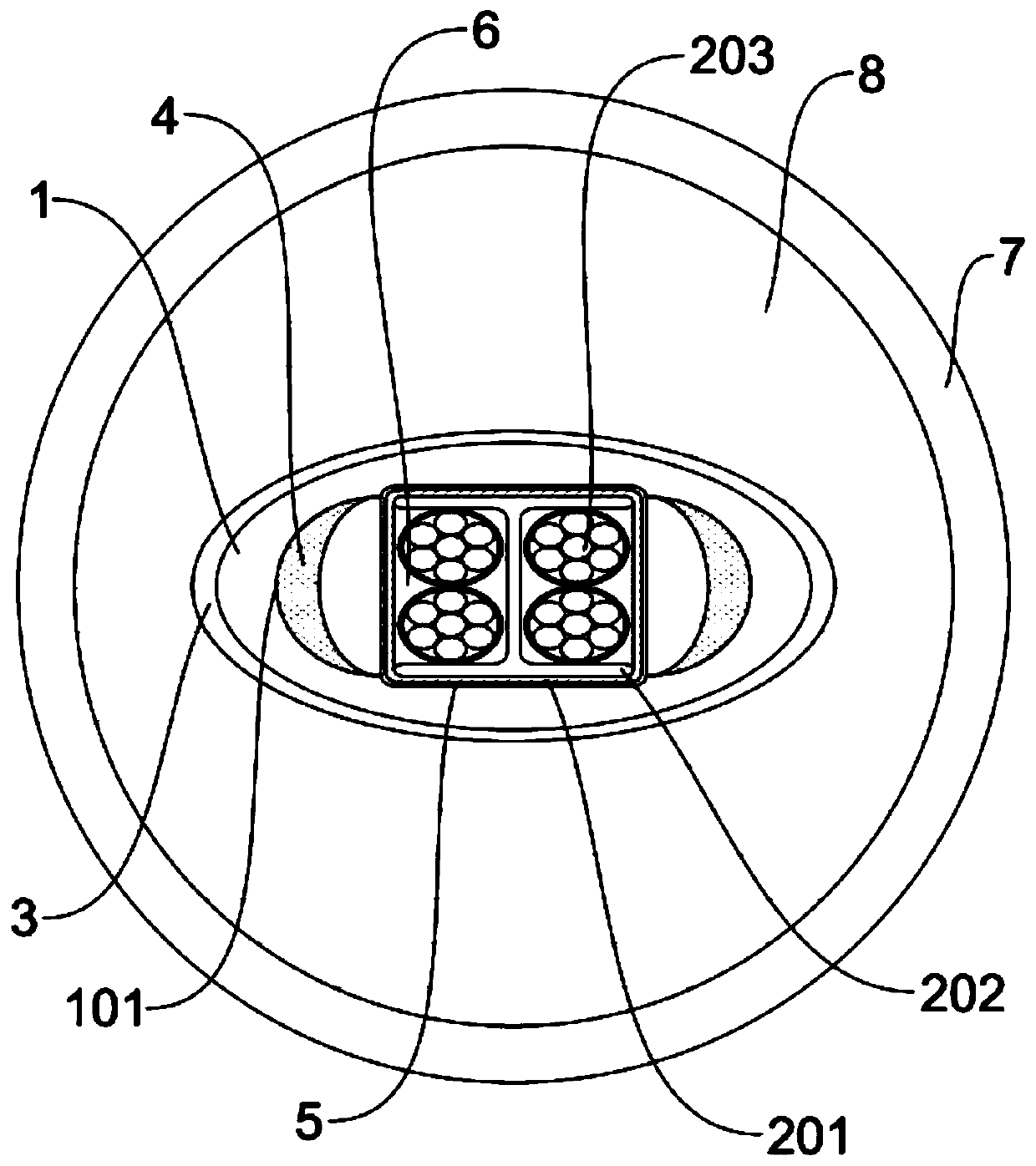

[0037] Such as figure 1 and figure 2 A submarine cable is shown, which includes:

[0038] The outer sheath 1 and the inner core tube 2, the cross section of the outer sheath 1 is oval, the cross section of the inner core tube 2 is a rounded rectangle, the outer sheath 1 tightly covers the outside of the inner core tube 2, and when the inner core tube When 2 is a rectangle with rounded corners, the long axis of the ellipse of the outer sheath 1 is parallel to the long side of the rectangle with rounded corners. This embodiment takes a square with rounded corners as an example;

[0039] The inner core tube 2 is composed of an inner sheath 201, an I-shaped frame 202 and a plurality of core wires 203. The core wire 203 is formed by tightly wrapping a plurality of non-woven fabric wrapping tapes 2032 outside the transmission line 2031. The transmission line 2031 is an optical fiber or Conductive wire, which plays the role of transmitting optical signal or electric power, is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com