Light distribution structure and element, related method and uses

A technology of light distribution and structure, applied in optical components, light guides, optics, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

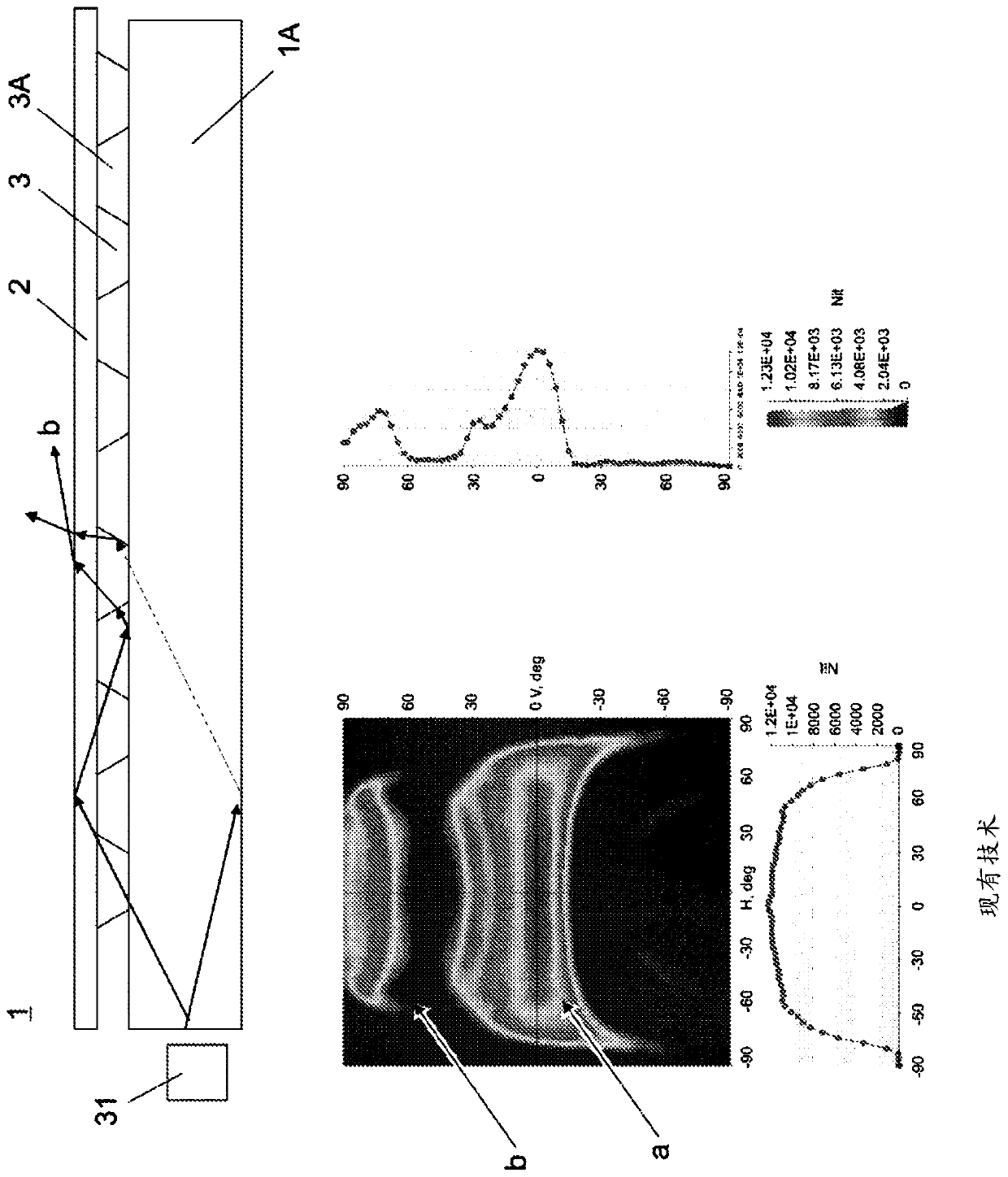

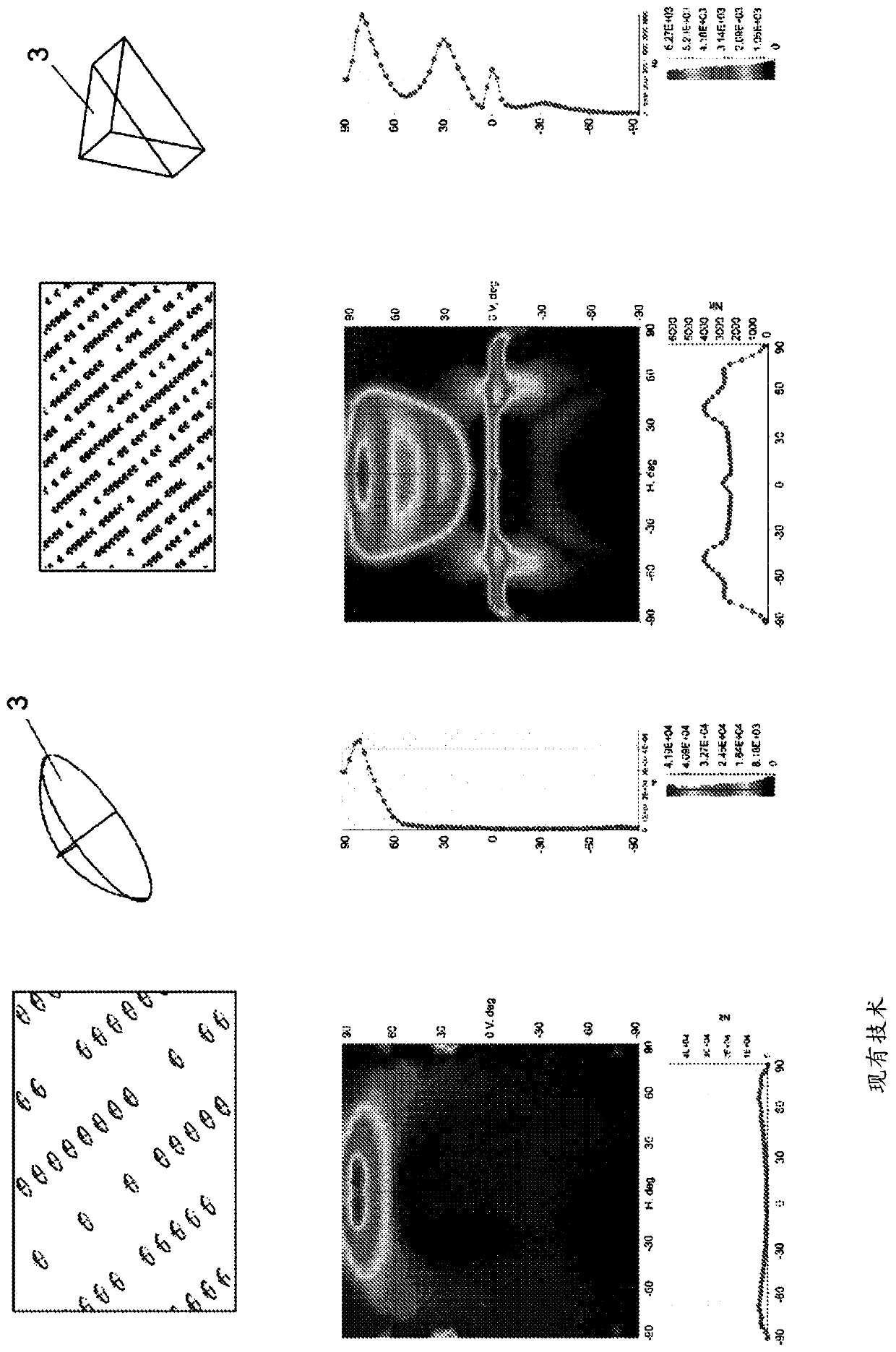

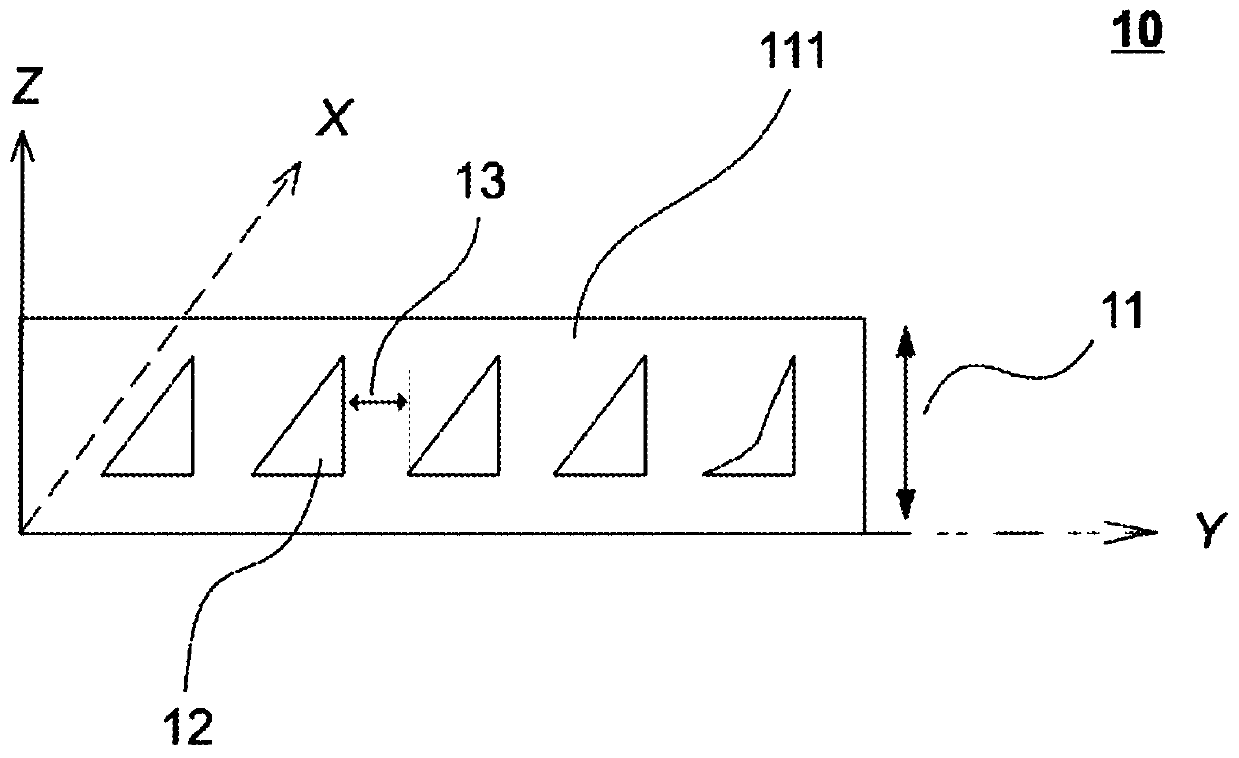

[0074] Detailed embodiments of the present invention are disclosed herein with reference to the accompanying drawings. Throughout the drawings, the same reference numerals are used to refer to the same components. The following citations are used for said artifacts:

[0075] 1, 1A, 2, 3, 3A – conventional light guides and their components;

[0076] 10-Light distribution layer structure;

[0077] 11, 11A-optical characteristic pattern;

[0078] 111, 111A - light transmissive carrier medium;

[0079] 12 - Optical (pattern) features;

[0080] 13 - optical channel;

[0081] 121, 122 - optical functional surfaces;

[0082] 100, 100A-light distribution element (light guide);

[0083] 101, 101A - optically transparent substrate;

[0084] 141 - Optical filter surface or layer;

[0085] 141A - holes provided in the surface of the optical filter;

[0086] 151 - adhesive;

[0087] 31 - light source;

[0088] 41 - brightness enhancement film, BEF (prior art);

[0089] 42 - re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com