Dust collector rolling brush structure convenient to disassemble and dust collector

A technology for vacuum cleaners and roller brushes, which is applied in the directions of vacuum cleaners, suction nozzles, cleaning equipment, etc., can solve the problems of short service life, inconvenient disassembly and assembly, etc., and achieves the effect of solving easy damage, convenient disassembly and assembly, and solving short lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

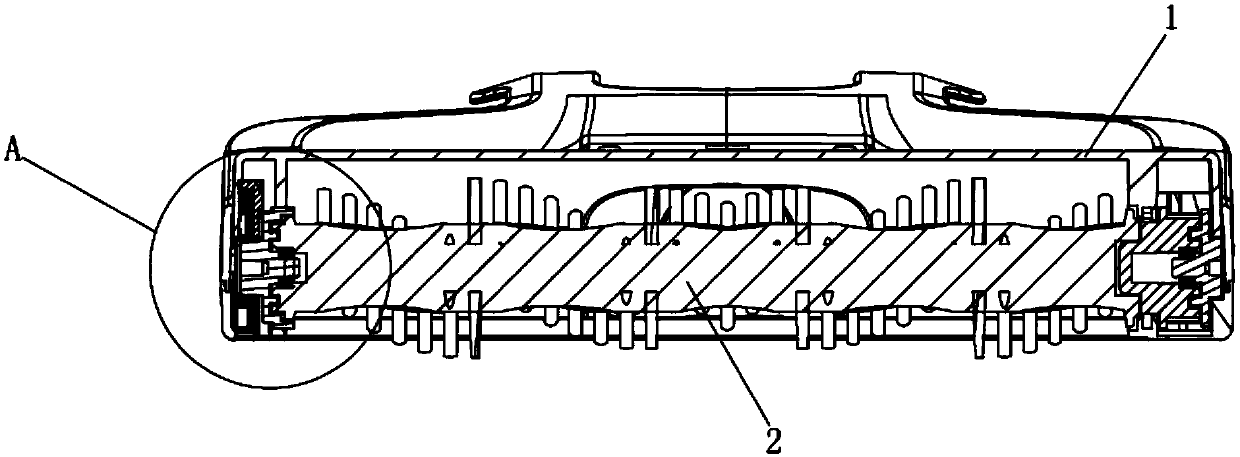

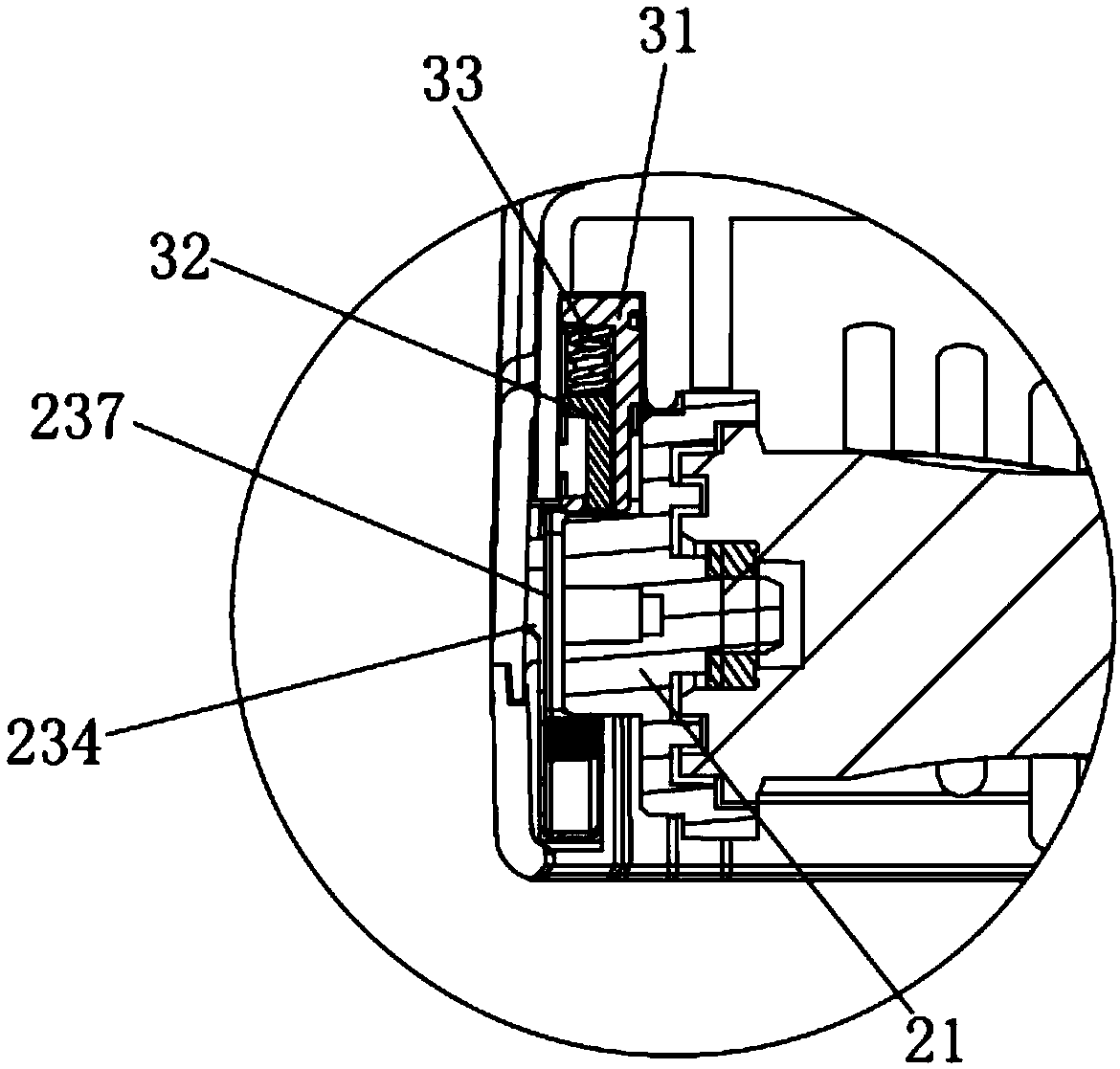

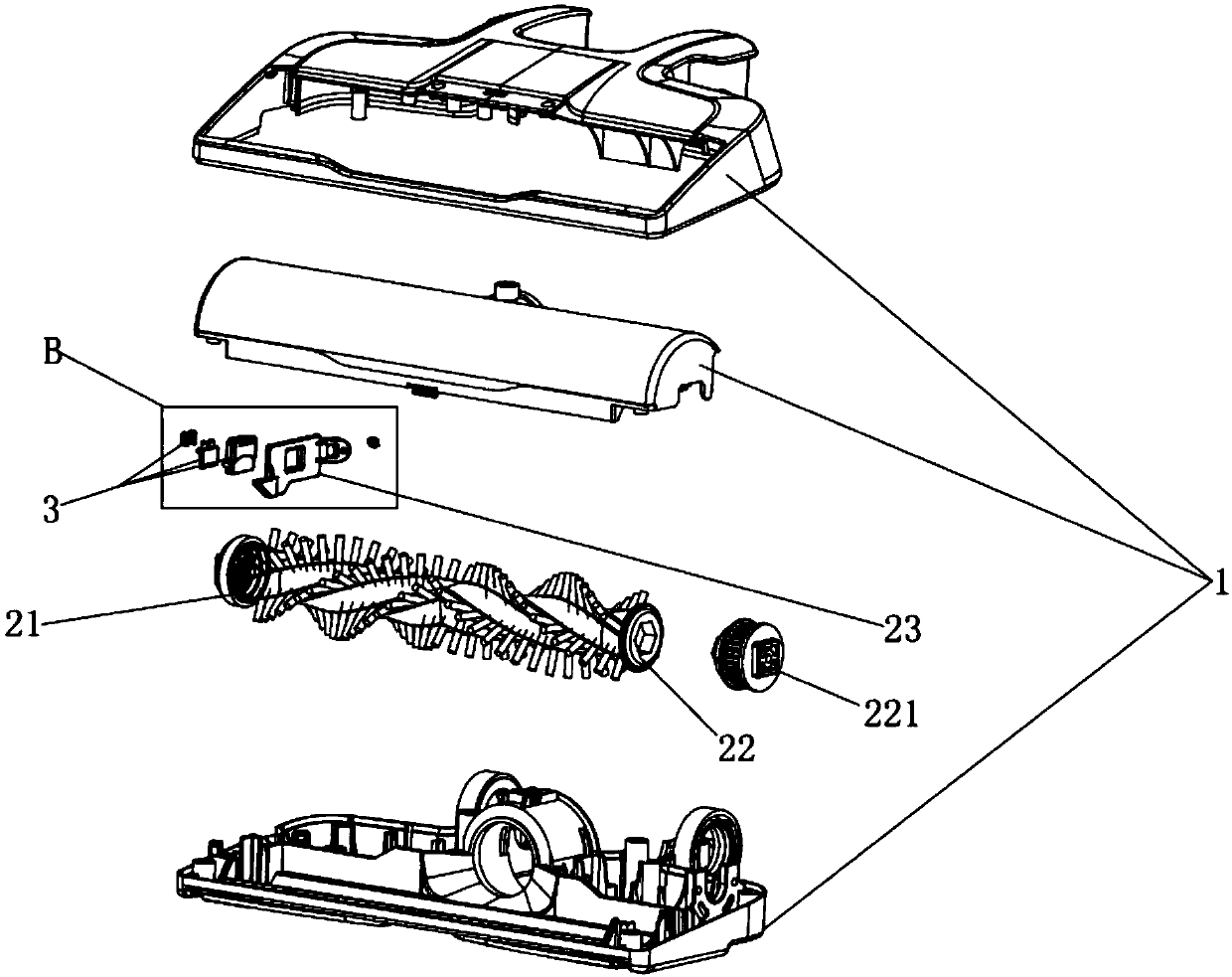

[0023] see Figure 1 to Figure 4 , the figure shows an easy-to-disassemble vacuum cleaner roller brush structure provided by Embodiment 1 of the present invention, which includes a roller brush 2 and a roller brush housing 1. The roller brush housing 1 may include upper and lower two shell units, and the roller The brush 2 is installed in the rolling brush shell 1, the rolling brush 2 has a first end 21 and a second end 22 opposite to each other, the second end 22 is connected with a pulley 221 to form a rolling drive for the rolling brush, the first end The part 21 contacts or connects with the detachable push plate 23, the third end 231 of the detachable push plate 23 extends into the roller brush housing 1, and the third end 231 is connected with a reset plate 232, between the reset plate 232 and the third end 231 An included angle a is formed between them, the reset plate 232 is connected with a tension spring 233, and the tension spring 233 is connected with the inner wal...

Embodiment 2

[0027] see Figure 1 to Figure 4 , the figure shows an easy-to-disassemble vacuum cleaner roller brush structure and vacuum cleaner provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: Disassembly The push plate 23 has a rectangular plate body as a whole, and a fourth end portion 234 opposite to the third end portion 231 is arranged on it. The fourth end portion 234 contacts or connects with the first end portion 21, so as to achieve a stable fit with the roller brush .

[0028] In order to ensure further stable cooperation with the roller brush, a triangular boss 235 is provided at the foot of the fourth end 234, and the triangular boss 235 contacts or connects with the first end 21, and the triangular boss can specifically be a right-angled triangular boss .

Embodiment 3

[0030] see Figure 1 to Figure 4 , the figure shows an easy-to-disassemble vacuum cleaner roller brush structure and vacuum cleaner provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: Disassembly A first rectangular hole 236 is opened on the push plate 23 , and a rib 237 is arranged on the edge of the first rectangular hole 236 . Through the setting of the above structure, on the one hand, the overall weight of the dismantling push plate can be reduced, and on the other hand, the deformable characteristics of the dismantling push plate can be realized by using the design of the rectangular hole, which is beneficial to the rolling brush to form a push to the dismantling push plate, forming an anti-rolling brush. Pop with greater pop force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com