A method for preparing intermediates by reducing glutathione indicating amino acid Maillard reaction

A technology of Maillard reaction and glutathione, which is applied in the field of food chemistry and food additives, can solve the problems of uncontrollable reaction process, poor water solubility of cysteine, difficulty in preparing intermediates, etc., and achieves feasibility and universality. Adaptability, enhance the sense of accomplishment and pleasure, and solve the effect of easy loss of flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

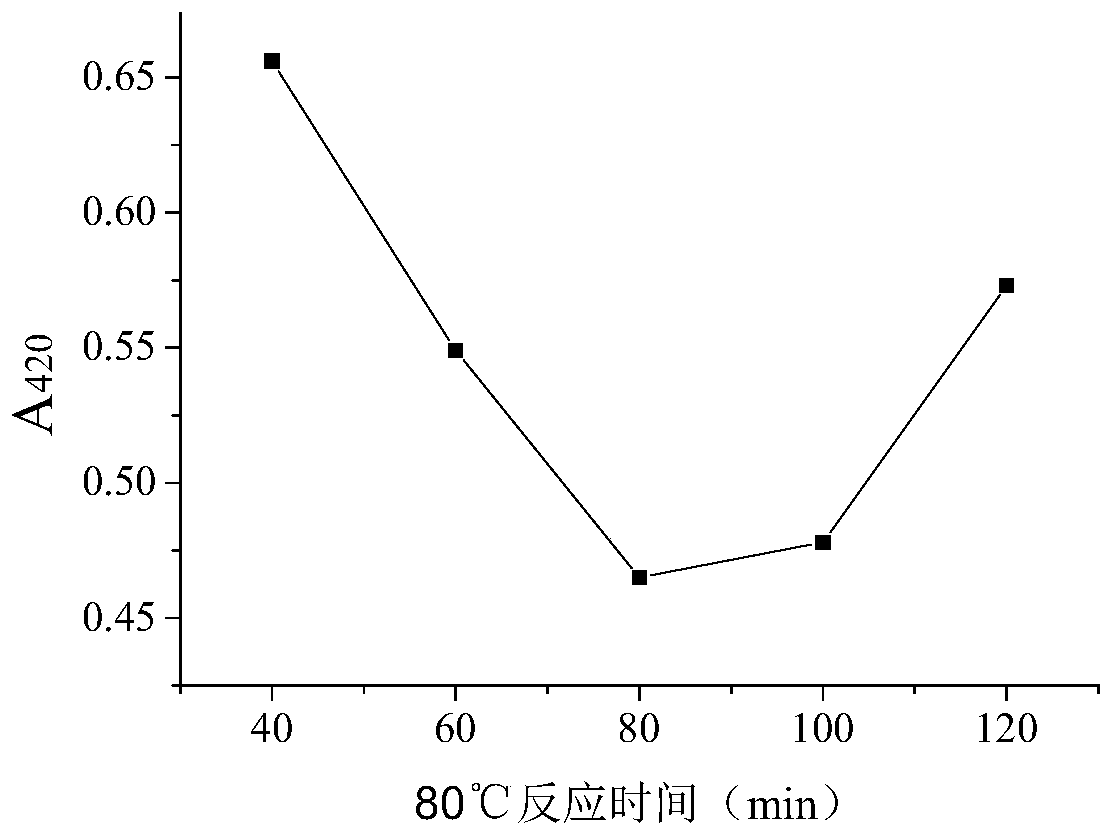

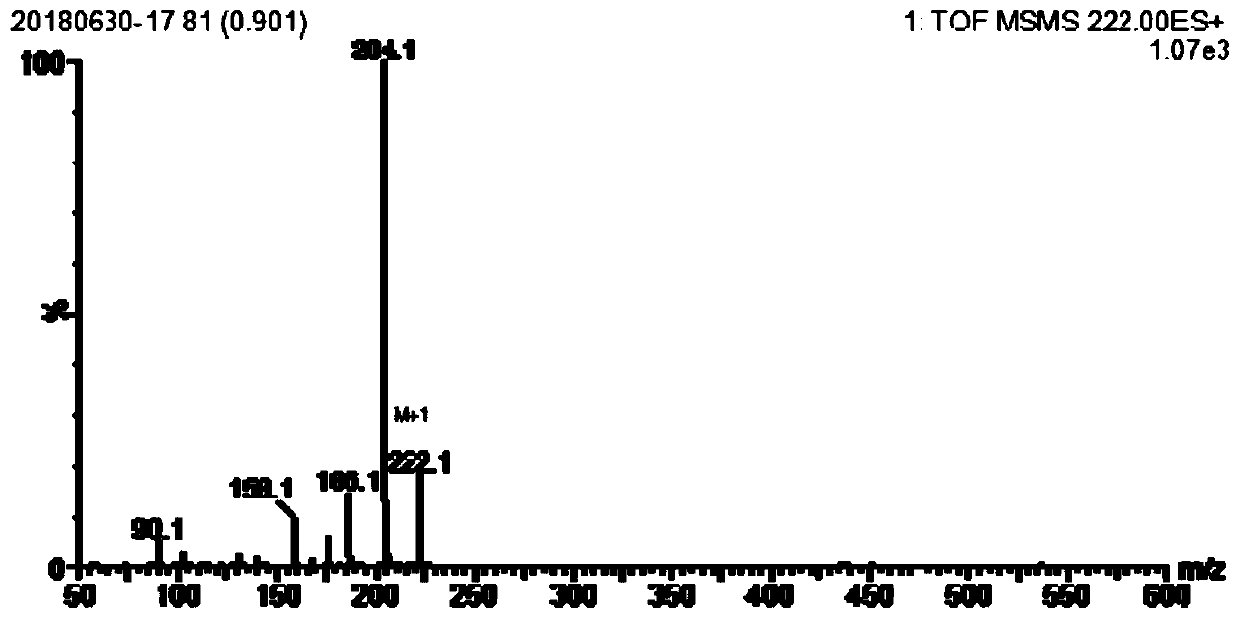

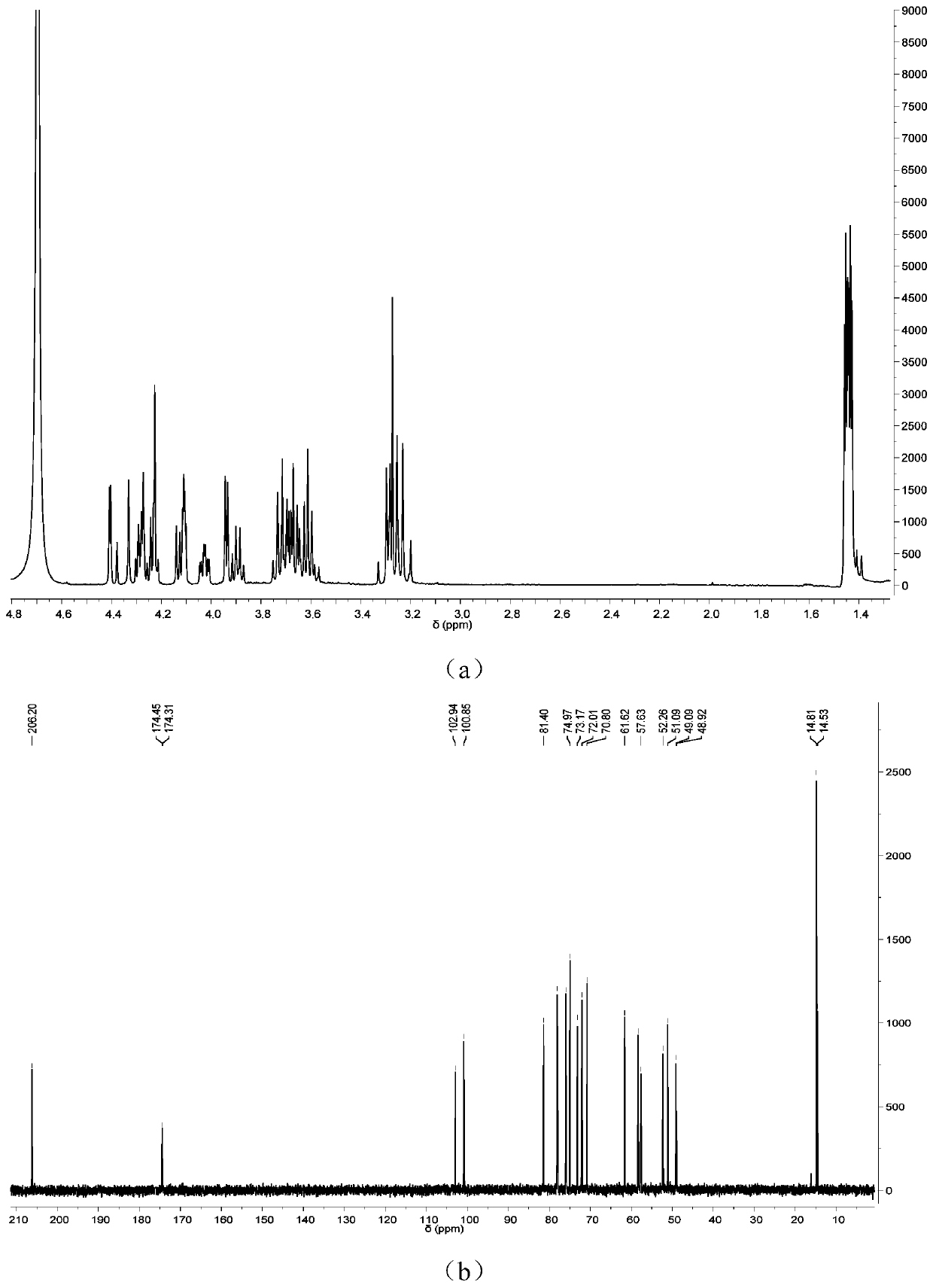

[0039] (1) Dissolve 17.8kg of alanine and 60kg of xylose in 1000kg of water, adjust the pH of the mixed solution to 8.0, react in a water bath at 80°C, sample 180L at 40, 60, 80, 100, and 120 minutes, and place on ice Cooling in the bath terminates the reaction;

[0040] (2) Add 1.8 kg of reduced glutathione to the five reaction solutions obtained above, and readjust the pH of the reaction solution to 8.0, transfer to a temperature-resistant and pressure-resistant bottle, and then raise the temperature to 120 ° C, the second stage high temperature Maillard reaction for 60 minutes, placed in an ice bath to cool to terminate the reaction, to obtain a variable temperature Maillard reaction solution;

[0041] (3) each part of variable temperature Maillard reaction solution is diluted 5 times respectively, measure the absorbance value under the wavelength 420nm, draw a curve according to the corresponding low temperature reaction time in the absorbance value and step (1), the resul...

Embodiment 2

[0044] (1) Dissolve 8 kg of cysteine and 19.8 kg of xylose in 800 kg of water, adjust the pH of the mixed solution to 7.5, react in a water bath at 100°C, and sample 130 L at 10, 20, 30, 40, 50, and 60 minutes respectively, Cool in an ice bath to terminate the reaction;

[0045] (2) Add 1.3kg of reduced glutathione to the six reaction solutions obtained above, and readjust the pH of the reaction solution to 7.5, transfer to a temperature-resistant and pressure-resistant bottle, and then raise the temperature to 130°C. Maillard reaction for 90 minutes, placed in an ice bath to cool to terminate the reaction, to obtain a variable temperature Maillard reaction solution;

[0046] (3) each part of variable temperature Maillard reaction solution is diluted 2 times respectively, measure the absorbance value under the wavelength 420nm, draw a graph according to the corresponding low temperature reaction time in the absorbance value and step (1), the result is as follows Figure 4 s...

Embodiment 3

[0049] (1) Dissolve 15kg of glycine and 60kg of ribose in 1000kg of water, adjust the pH of the mixed solution to 6.0, react in a water bath at 90°C, take 150L samples at 20, 40, 60, 80, 100, and 120 minutes, and place them in an ice bath cooling to terminate the reaction;

[0050] (2) Add 3kg of reduced glutathione to the six reaction solutions obtained above, and readjust the pH of the reaction solution to 6.0, transfer to a temperature-resistant and pressure-resistant bottle, and then raise the temperature to 110°C. Lad reaction 120min, placed in ice bath cooling to terminate the reaction, to obtain variable temperature Maillard reaction liquid;

[0051] (3) each part of variable temperature Maillard reaction solution is diluted 50 times respectively, measure the absorbance value under the wavelength 420nm, draw a graph according to the corresponding low temperature reaction time in the absorbance value and step (1), the result is as follows Image 6 shown. Depend on Im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com