Control transmission mechanism of swinging type granulator

A technology of transmission mechanism and granulator, which is used in transmission devices, mechanical equipment, extrusion and granulation of raw materials, etc., can solve the problems of poor quality, low efficiency, rough end face of particles, etc., and achieves improved surface smoothness, high efficiency, Good quality particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

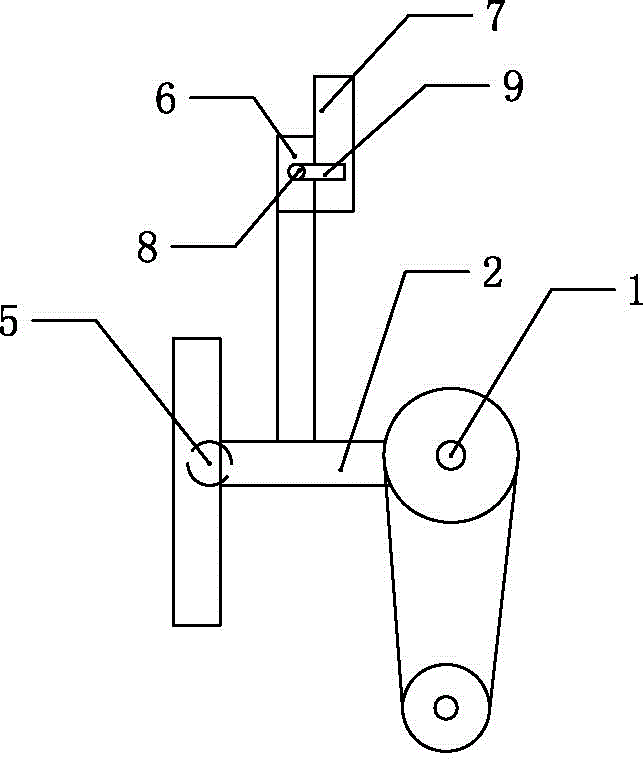

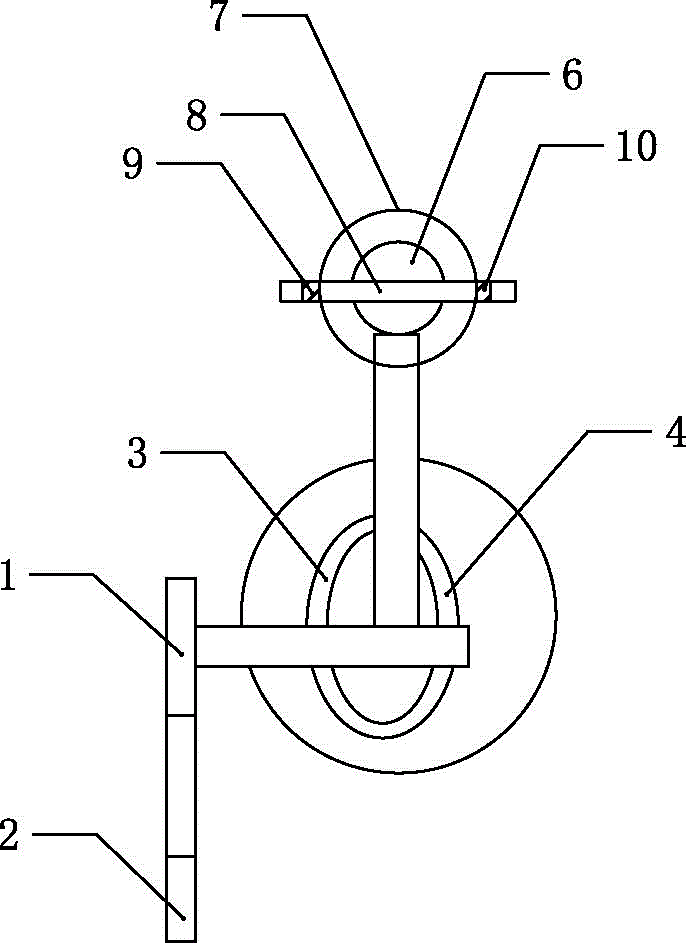

[0017] Such as figure 1 , figure 2 As shown, the control transmission mechanism of the oscillating granulator of the present invention includes a large pulley, a small pulley, a belt and a push rod 1, the large pulley is located above the small pulley, and the belt is wound on the small pulley of the large pulley, and the push rod 1 is vertical Located at the center of the inner side of the large pulley; the crankshaft 2 is connected to the push rod 1, and the crankshaft 2 is a shaft with a peak in the middle, and the end of the crankshaft 2 is connected to a sliding disc, and the end of the sliding disc is provided with a slideway, which includes The first slideway 3 and the second slideway 4 are connected and arranged vertically, and the middle parts of the first slideway 3 and the second slideway 4 are recessed outward along the radial direction of the sliding disc, the first slideway 3 and the second slideway 4 The second slideway 4 is provided with a boss at the crossin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com