Probe type filling valve head full-automatic production equipment and assembling method

A technology for production equipment and filling valves, which is applied in the field of full-automatic production equipment and assembly of probe-type filling valve valve heads, and can solve the problems of too tight or too loose steel ring assembly, uneven filter screen assembly, and probe assembly. Problems such as unevenness can be solved to achieve the effects of ensuring stability, improving assembly quality, and improving press-fitting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below in conjunction with the drawings.

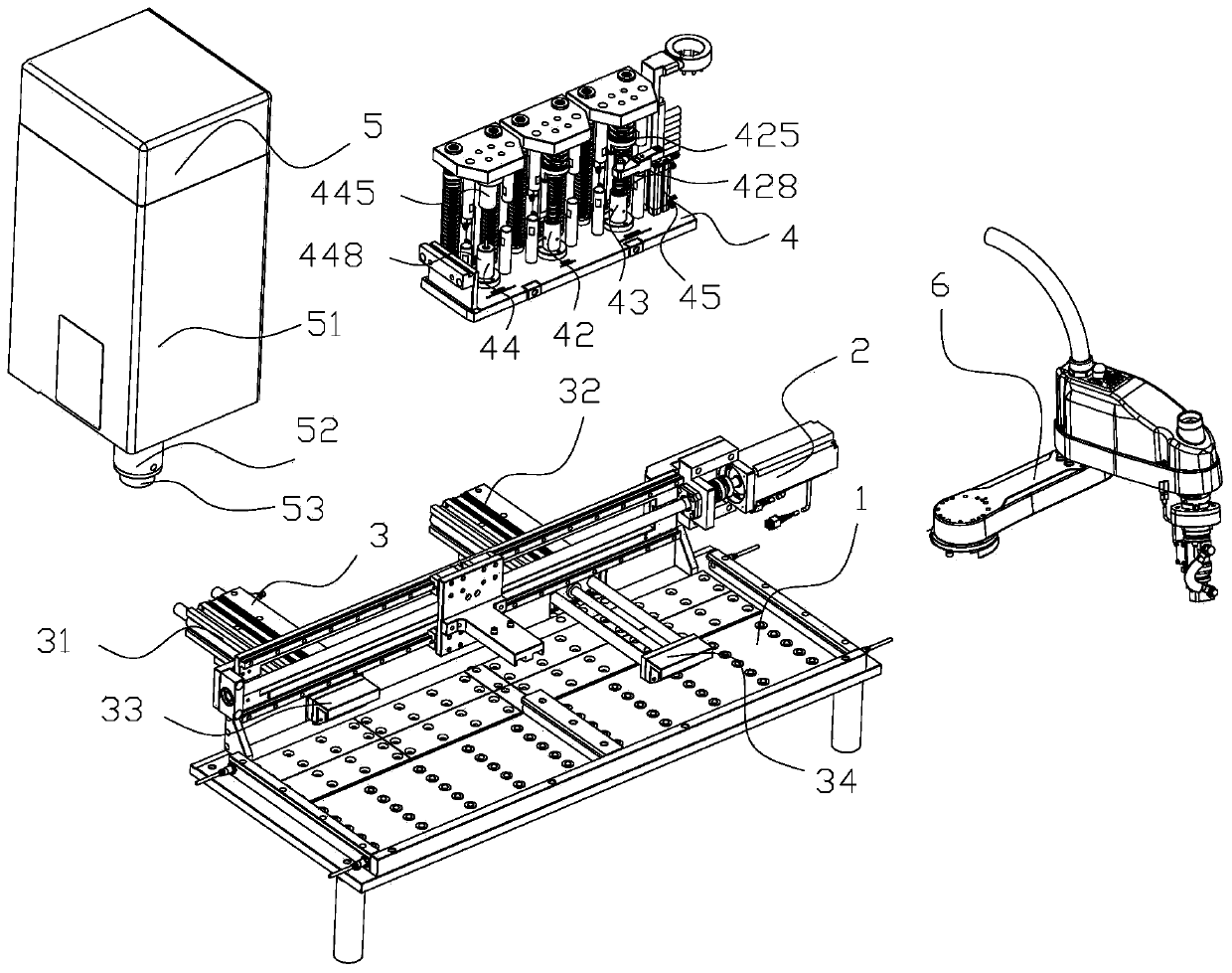

[0025] Such as figure 1 Shown, a probe-type filling valve valve head fully automatic production equipment, the equipment includes a frame 1 and a loading and unloading device 6, a horizontal drive device 2, a pushing drive device 3, an assembly device 4 and a stamping device 5 The loading and unloading device 6 is an automatic loading manipulator, which is used for loading and unloading different parts through the automatic loading manipulator; the horizontal driving device 2 is used to drive the assembly device 4 to move and position horizontally; The driving device 3 is used to push out the assembling device 4; the assembling device 4 and the punching device 5 cooperate to press and assemble the oil valve.

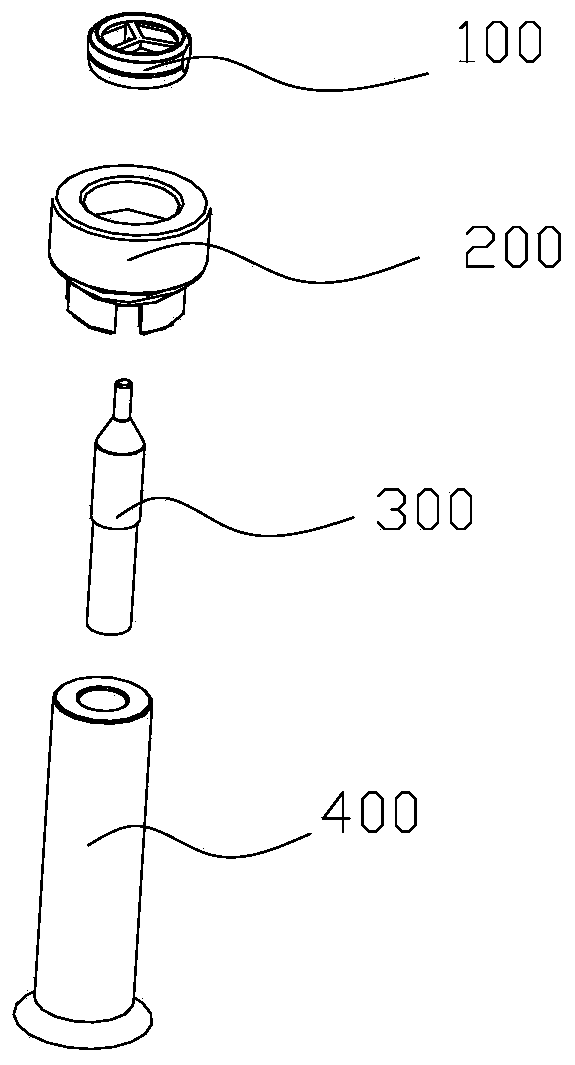

[0026] Such as figure 2 As shown, the figure includes the valve body 400, the probe 300, the steel ring 200, the filter screen 100 and the rod head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com