Anti-breaking foil device, 9μm~20μm copper foil post-processing anti-breaking foil method, post-processing machine

A post-processing machine and copper foil technology, applied in measuring devices, program control, instruments, etc., can solve problems such as unfavorable copper foil safety, achieve the effects of avoiding memory effects, improving processing speed, and preventing foil breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

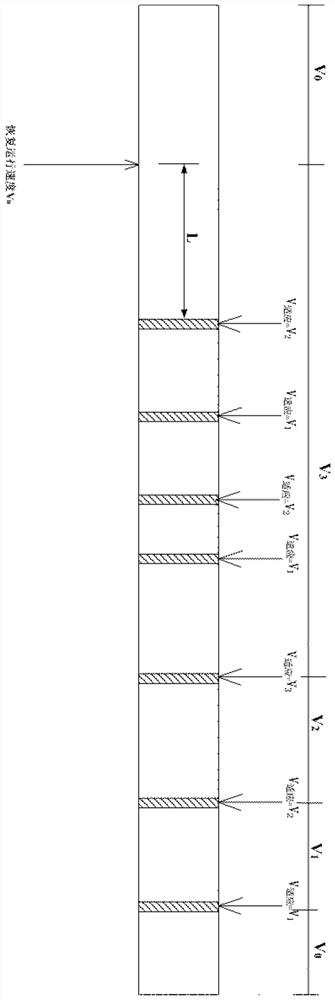

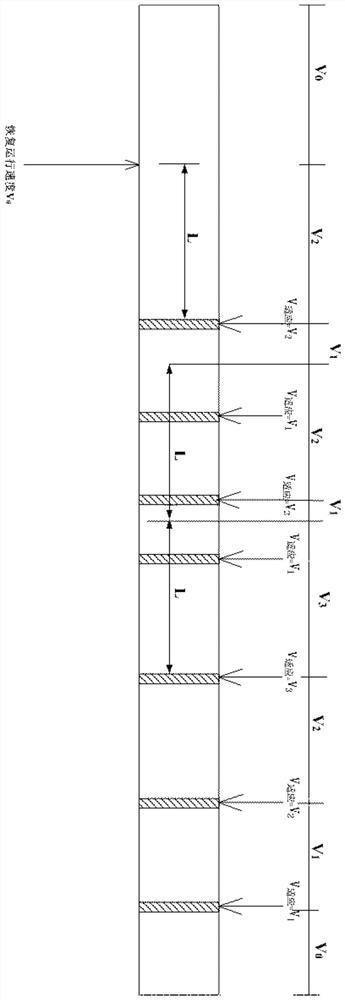

[0074] Embodiment 1, an anti-broken foil processing device of an electrolytic copper foil post-processing machine (single machine), which is installed on the electrolytic copper foil post-processing machine, and the anti-breaking foil processing device includes: a thickness gauge component 1 and a control system;

[0075] The thickness gauge assembly includes at least 4 thickness gauges, wherein the 4 thickness gauges are arranged in pairs on both sides of the copper foil banner, and the 4 thickness gauges are perpendicular to the advancing direction of the copper foil (that is, the 4 thickness gauges The thickness gauge is on the banner of the copper foil, that is, on one section); two thickness gauges distributed on one side of the copper foil are used to measure the thickness of the copper foil at the edge and the area adjacent to the edge;

[0076] The thickness gauge assembly 1 is connected to the control system;

[0077] The control system is connected with the post-proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com