Residue processing device

A technology for treating equipment and residues, applied in water supply equipment, indoor sanitary pipeline installations, buildings, etc., can solve the problems of machine weight, high cost, coarse grinding particles, etc., and achieve simple structure, simple and hygienic operation, and convenient installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the following examples.

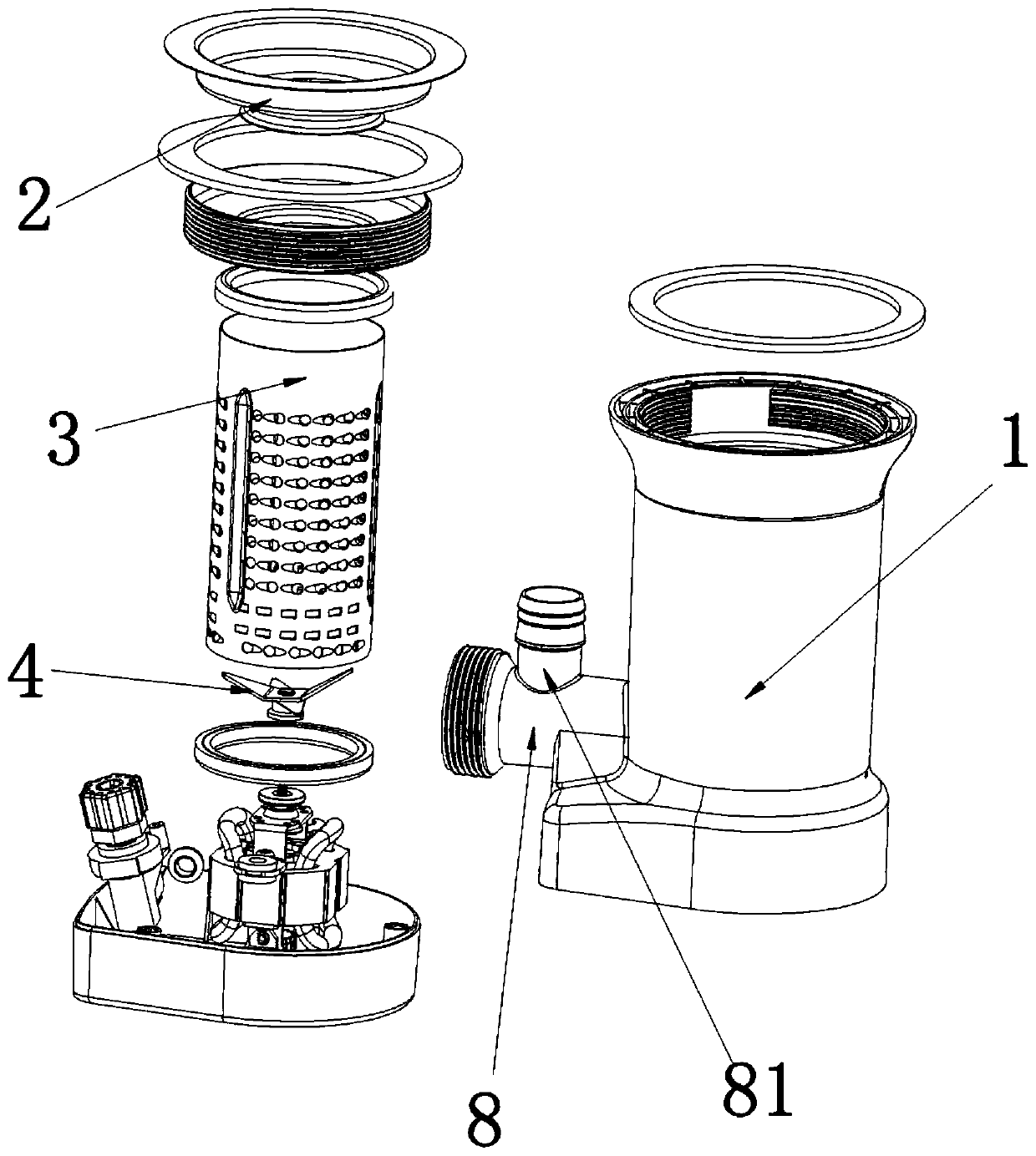

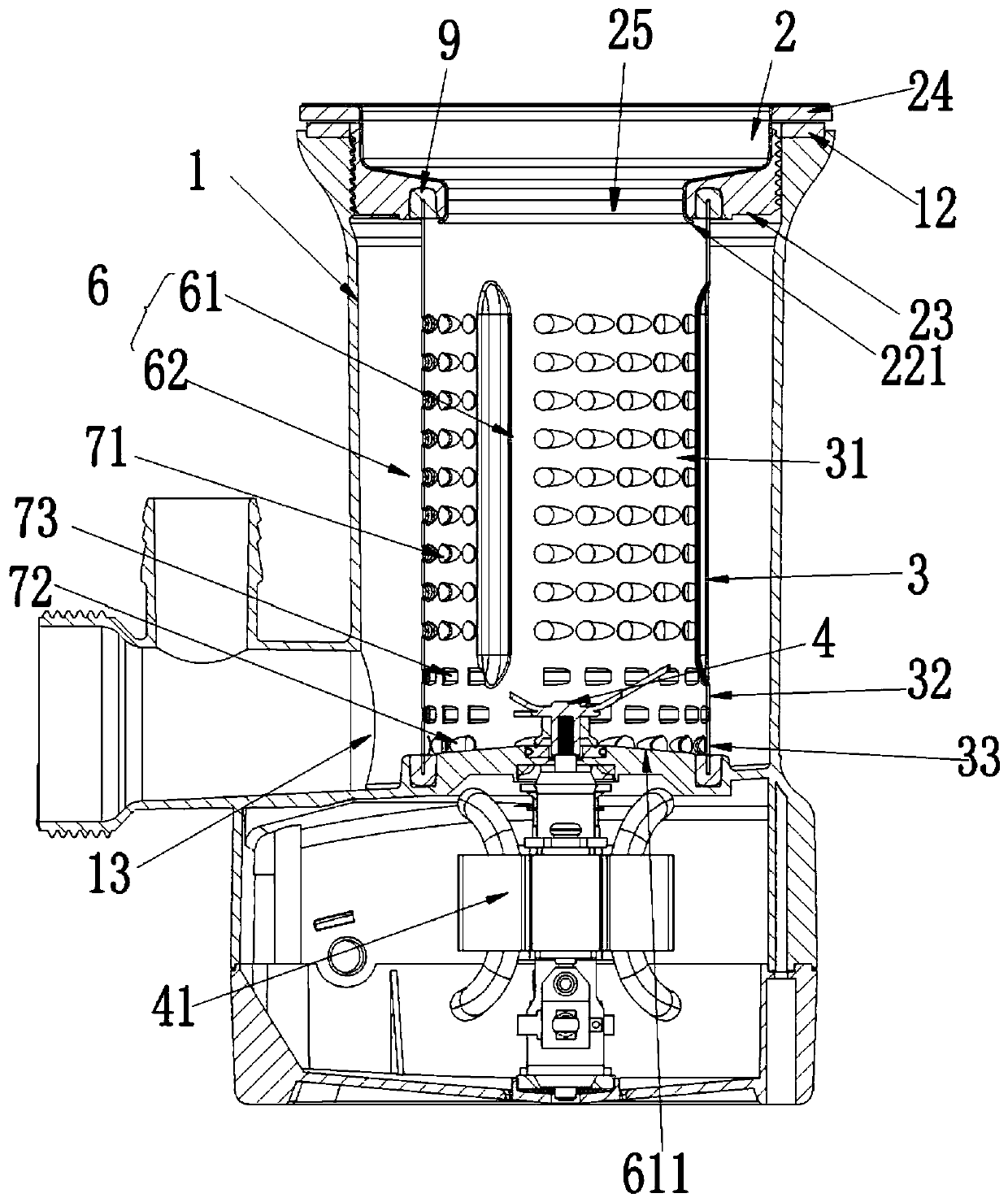

[0027] A specific embodiment of the residue processing device of the present invention, such as figure 1 with image 3 As shown, it includes a flow guide 2, a housing 1 and a filter cartridge 3. The housing 1 is provided with a liquid discharge port 13 for discharging residue. In the middle of the deflector 2 is provided a deflector 25 for the residue to pass through.

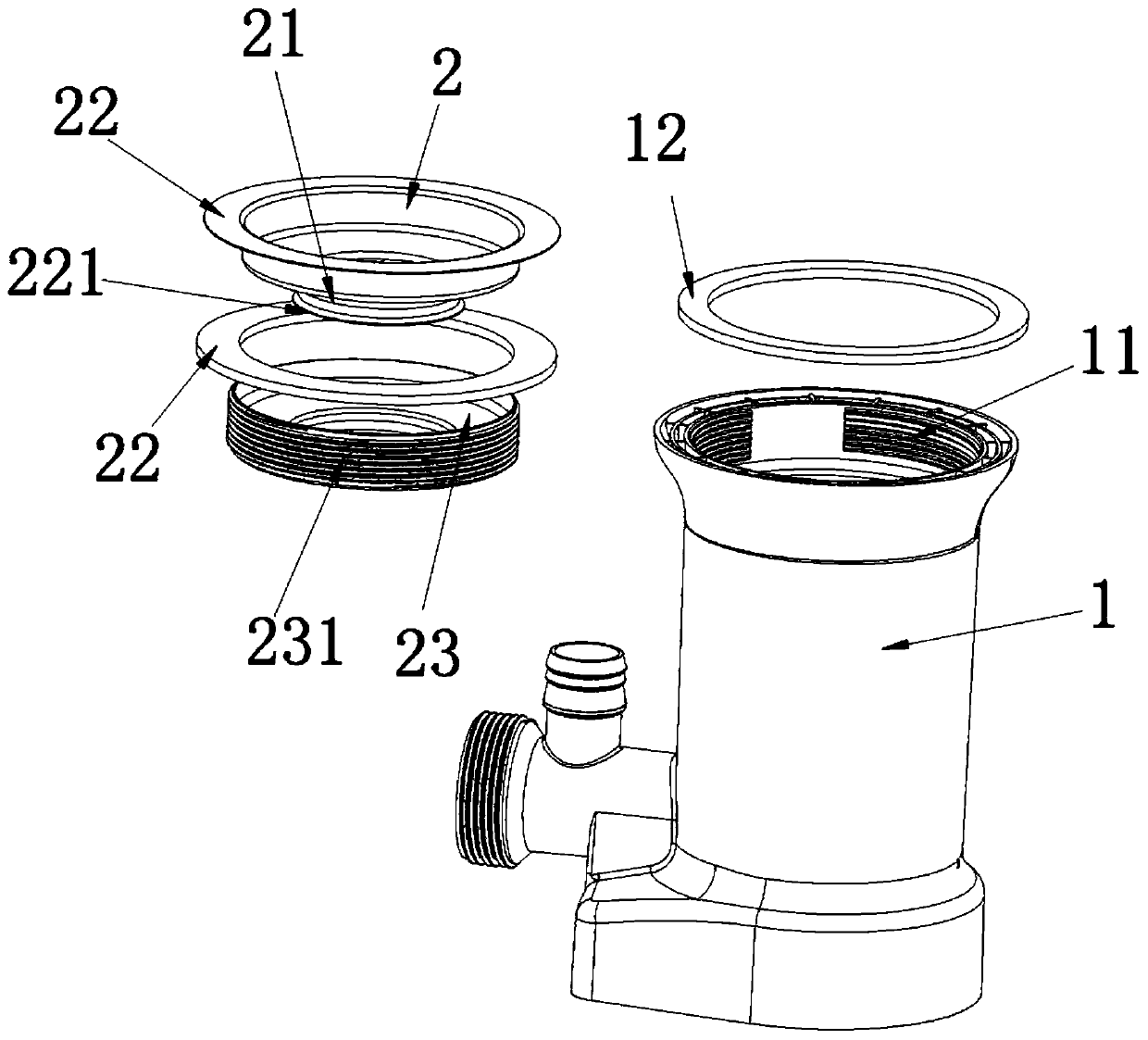

[0028] In this embodiment, in order to facilitate the removal and installation of the residue processing device, the air guide 2 is detachably mounted on the top of the housing 1 to jointly enclose the processing cavity 6. Please see figure 2 The flow guide 2 includes a vertical flow guide 21 and a lip 22 located at the top end of the flow guide 21 and extending outward. In the assembled state, the guide portion 21 of the guide member 2 is fixedly connected to the inside of the housing 1, and a clamping space is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com