Monitoring camera mounting bracket convenient to adjust

A technology for monitoring cameras and installing brackets, which is applied in the direction of machine tables/brackets, supporting machines, mechanical equipment, etc., which can solve the problems of inconvenient angle and position adjustment, inconvenient camera loading and unloading, and difficulty in meeting people's daily needs, so as to solve the problem of angle and position Inconvenient to adjust, easy to replace and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

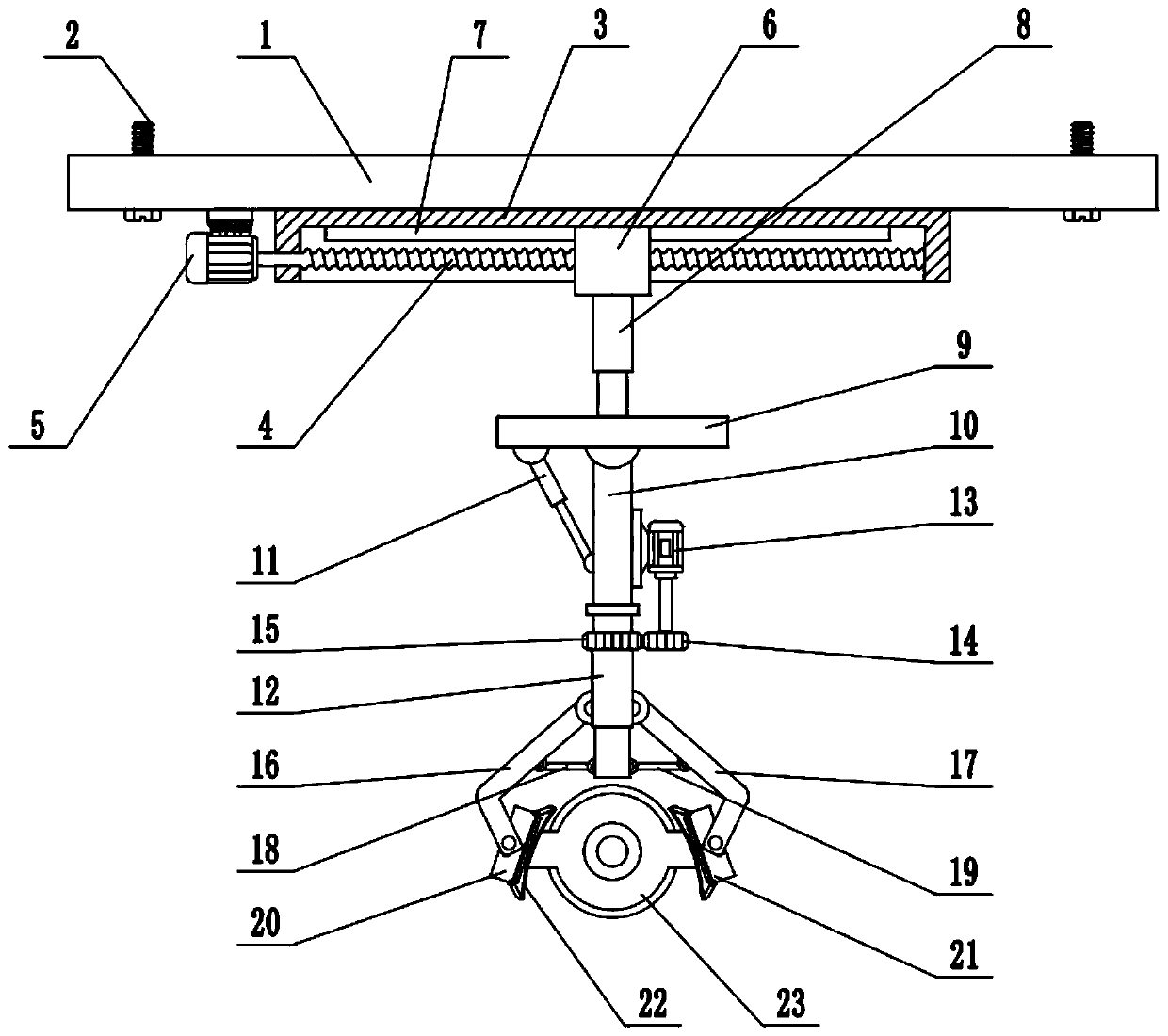

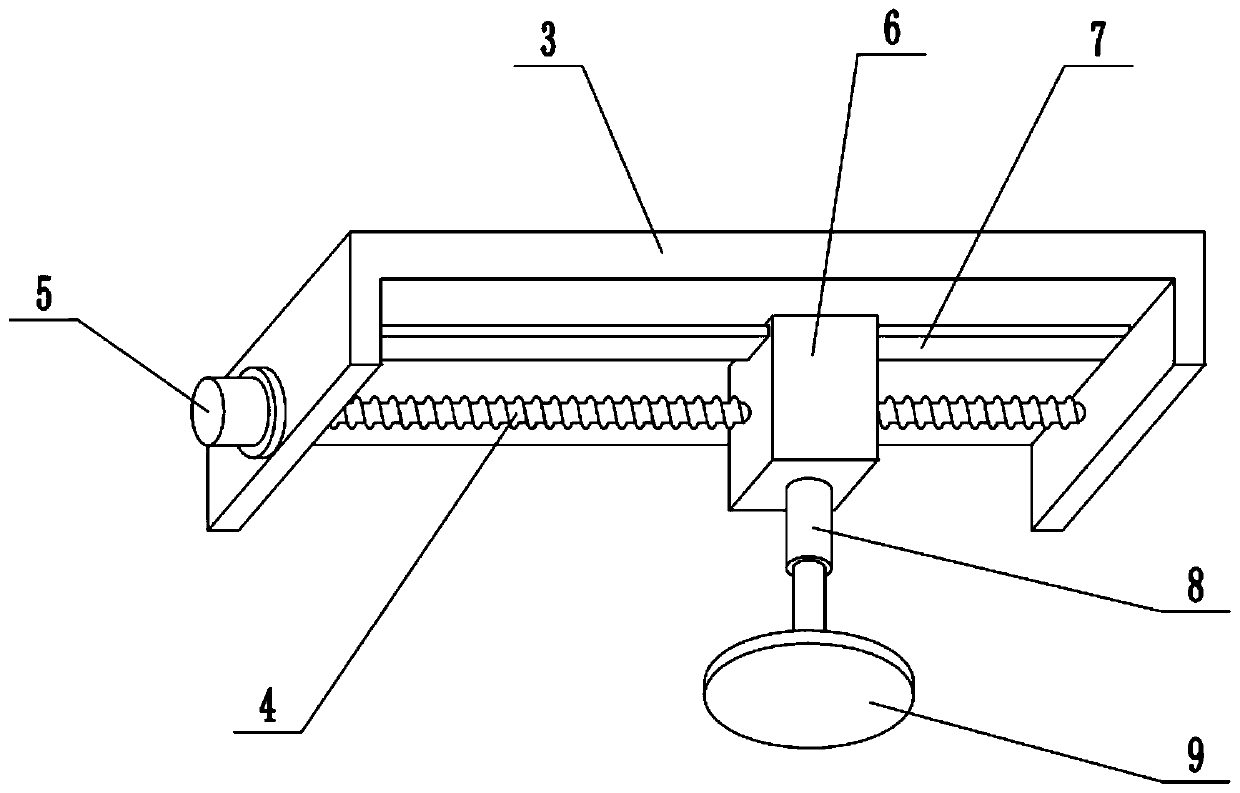

[0023] see Figure 1-3 , in the embodiment of the present invention, a monitoring camera mounting bracket that is easy to adjust includes a mounting plate 1, a fixing bolt 2, a fixing frame 3 and a camera 23, the mounting plate 1 is fixed on the ceiling by the fixing bolt 2, and the lower part of the mounting plate 1 The surface is fixedly connected with a fixed frame 3, and the inside of the fixed frame 3 is equipped with a screw rod 4, and the left and right ends of the screw rod 4 are respectively connected to the side walls of the fixed frame 3 for rotation, and the outer wall of the fixed frame 3 is fixedly connected with the first motor 5 , the first motor 5 is a forward and reverse motor, the middle part of the screw rod 4 is provided with a slider 6, the slider 6 is screwed to the screw rod 4, the top of the fixed frame 3 is equipped with a slide rail 7, and the top of the slider 6 is embedded Inside the slide rail 7, the slide block 6 is slidably connected with the sl...

Embodiment 2

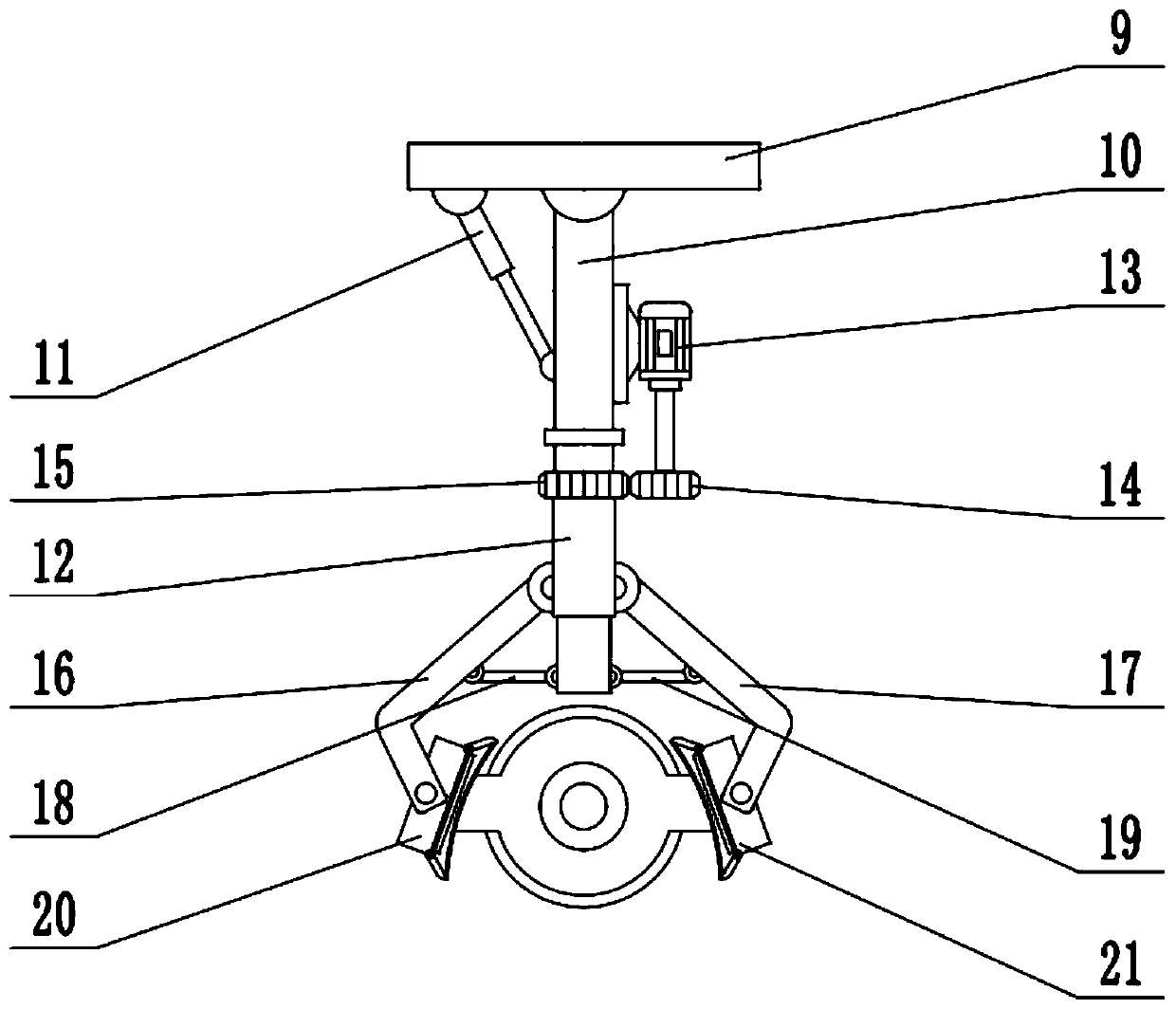

[0025] On the basis of Embodiment 1, the side wall of the swing rod 10 is fixedly connected with the second motor 13, the second motor 13 is a forward and reverse motor, the shaft extension end of the second motor 13 is provided with a driving gear 14, and the third telescopic A driven gear 15 is set on the mechanism 12, and the driving gear 14 meshes with the driven gear 15 to control the positive and negative rotation of the second motor 13, which can drive the positive and negative rotation of the driving gear 14, thereby driving the third telescopic mechanism through the driven gear 15 12 is reversed, thereby driving the camera 23 to rotate, thereby adjusting the angle of the camera 23 according to actual needs.

Embodiment 1、 Embodiment 2

[0026] In conjunction with Embodiment 1 and Embodiment 2, the working principle of the present invention is: the camera 23 is placed between the left clamping plate 20 and the right clamping plate 21, the third telescopic mechanism 12 is controlled to shorten, and the left connecting rod 18, the right The connecting rod 19 drives the left clamping arm 16 and the right clamping arm 17 respectively, so that the camera 23 is clamped by the left clamping plate 20 and the right clamping plate 21, so that the camera 23 remains fixed, and the installation is very convenient for replacement and maintenance The camera 23, during the working process, the camera 23 controls the forward and reverse rotation of the second motor 13, which can drive the driving gear 14 forward and reverse, thereby driving the third telescopic mechanism 12 forward and reverse through the driven gear 15, thereby driving the camera 23 to rotate, Thereby, according to actual needs, adjust the angle of camera 23, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com