Self-excited microjet control multi-tube oscillator

A micro-jet, self-excited technology, applied in the field of self-excited micro-jet control multi-tube oscillator, gas jet control such as special equipment necessary for refrigeration machinery, can solve the problem of high energy consumption, achieve small size and good reliability , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

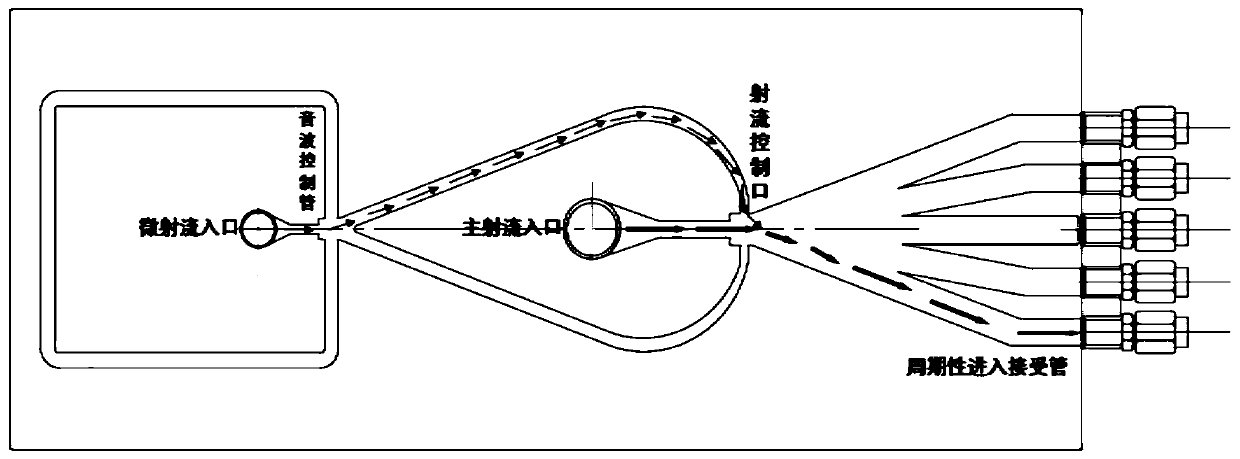

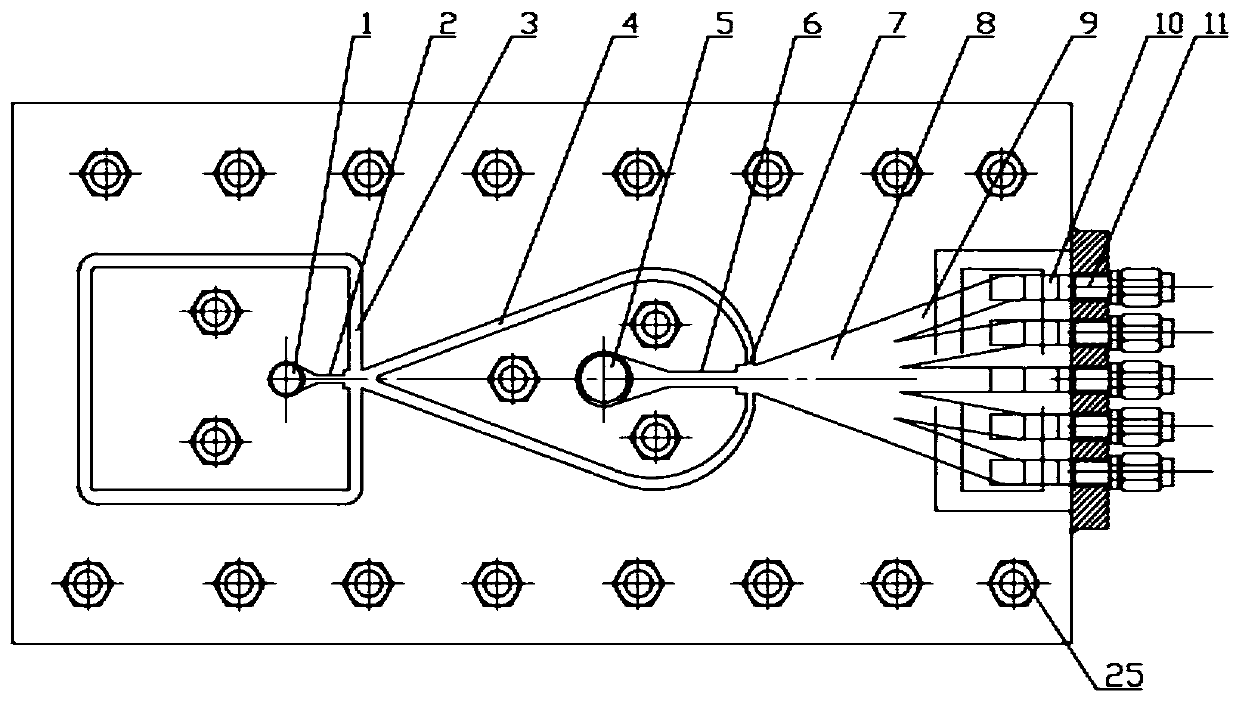

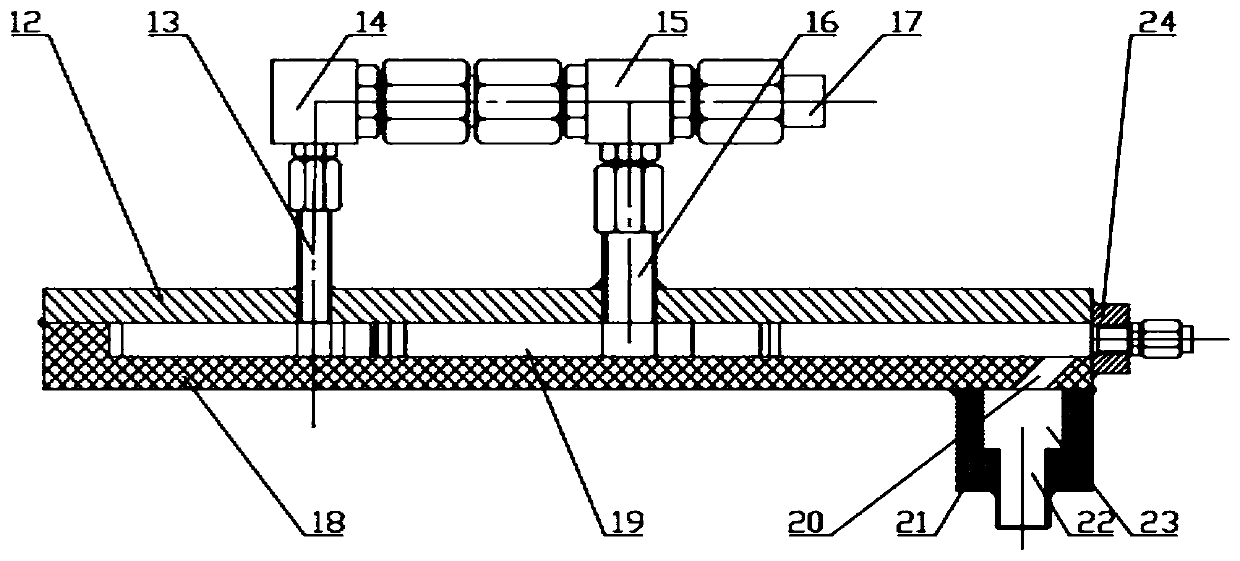

[0029] A typical implementation of the present invention is as follows:

[0030]The same gas source fluid separated from the main jet and equal to the total pressure of the main jet is introduced from the outside into the self-excited oscillation cavity, and self-excited oscillations are performed to generate periodic micro-jet, and the main jet is pushed from the vertical excitation port on the side of the attached wall. The way of pulling the main jet makes the main jet oscillate, thereby increasing and maintaining the total pressure. The self-exciting oscillating cavity uses a sonic oscillating jet generator as the micro-jet controller of the present invention, so that the main jet is distributed. And the change of the length of the sound wave control tube can change the switching frequency of the micro-jet attached to the wall.

[0031] Such as image 3 As shown, the self-excited micro-fluidic control multi-tube oscillator of the present invention mainly includes an osci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com