Frequency adjustable sonic wave fluidic oscillator

An oscillator and sound wave technology, applied in the jet engineering of pressurized gas and the field of gas expansion refrigeration, can solve the problems of low refrigeration efficiency and obstacles to the popularization and application of wall-attached oscillators, and achieve the effect of low cost, high power and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0033] A typical implementation of the present invention is as follows:

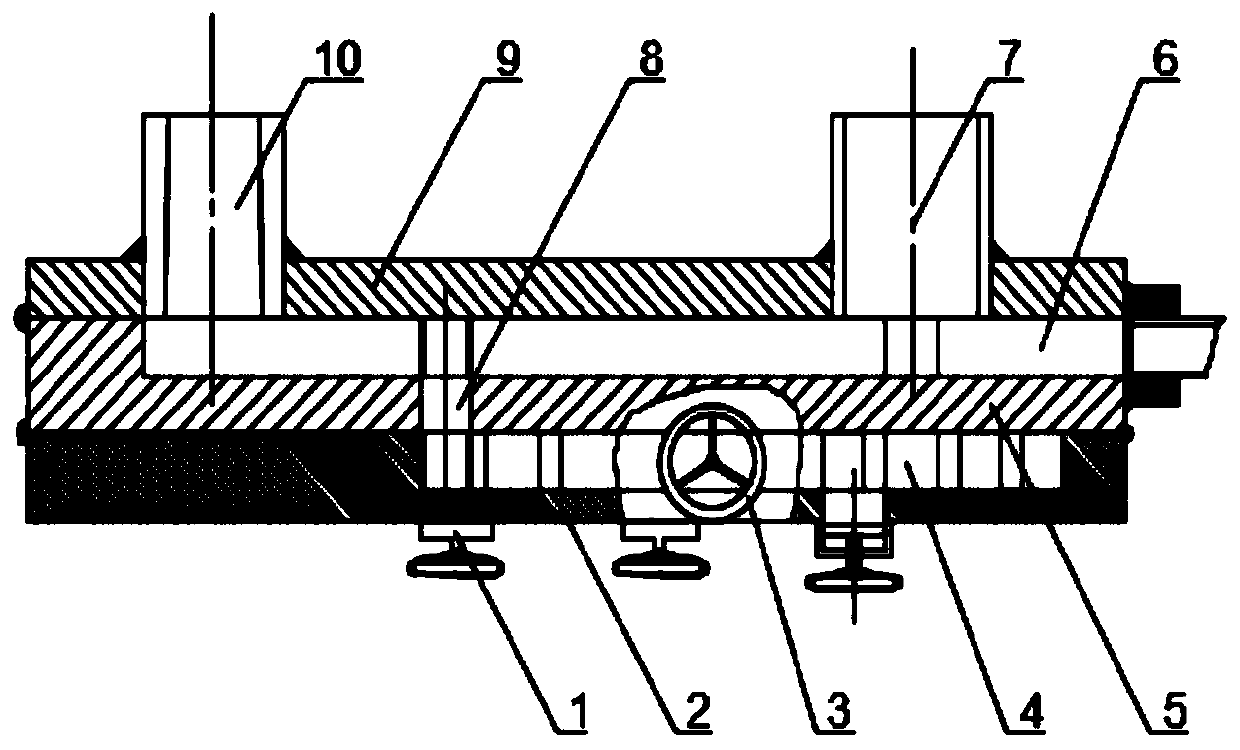

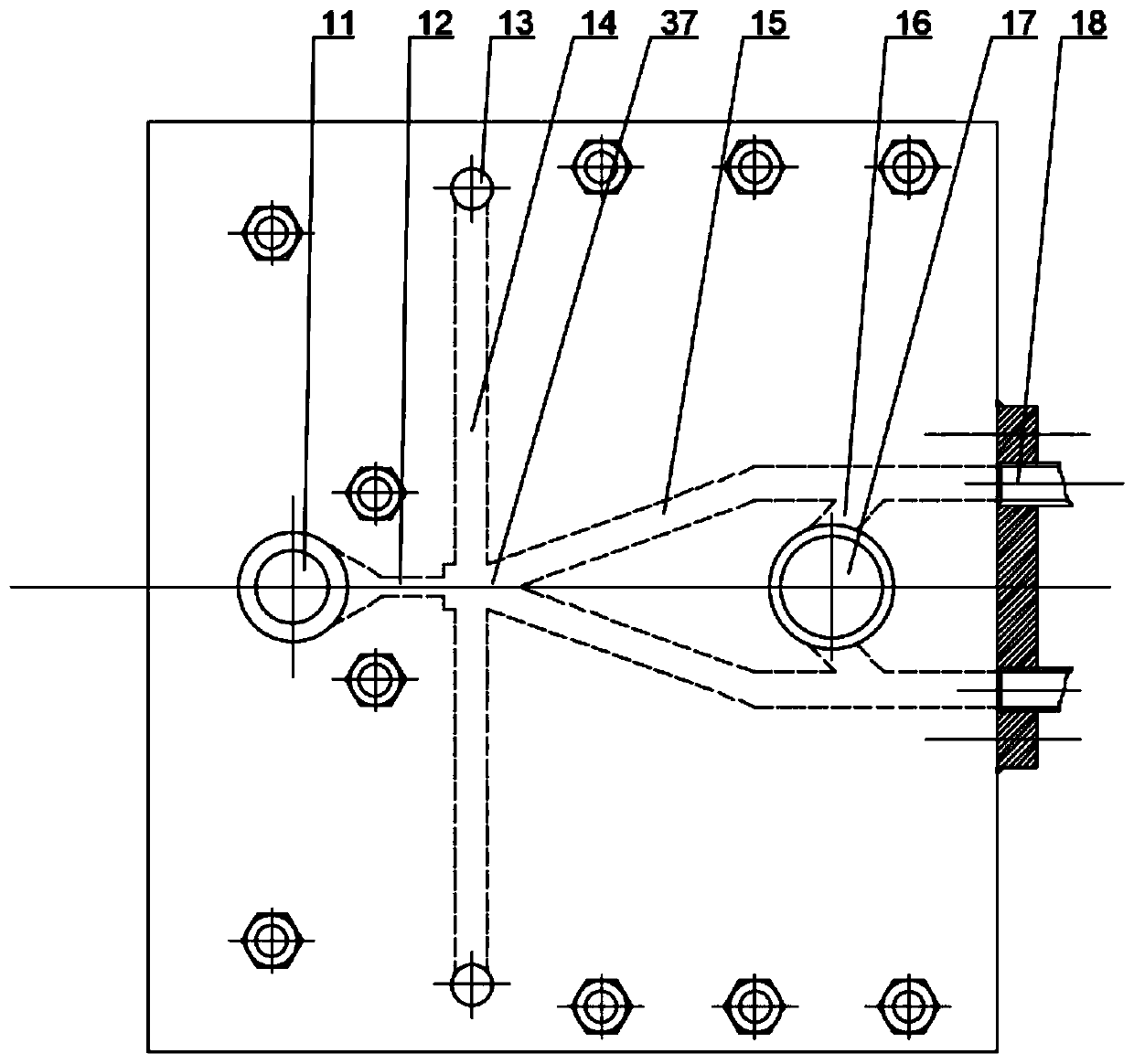

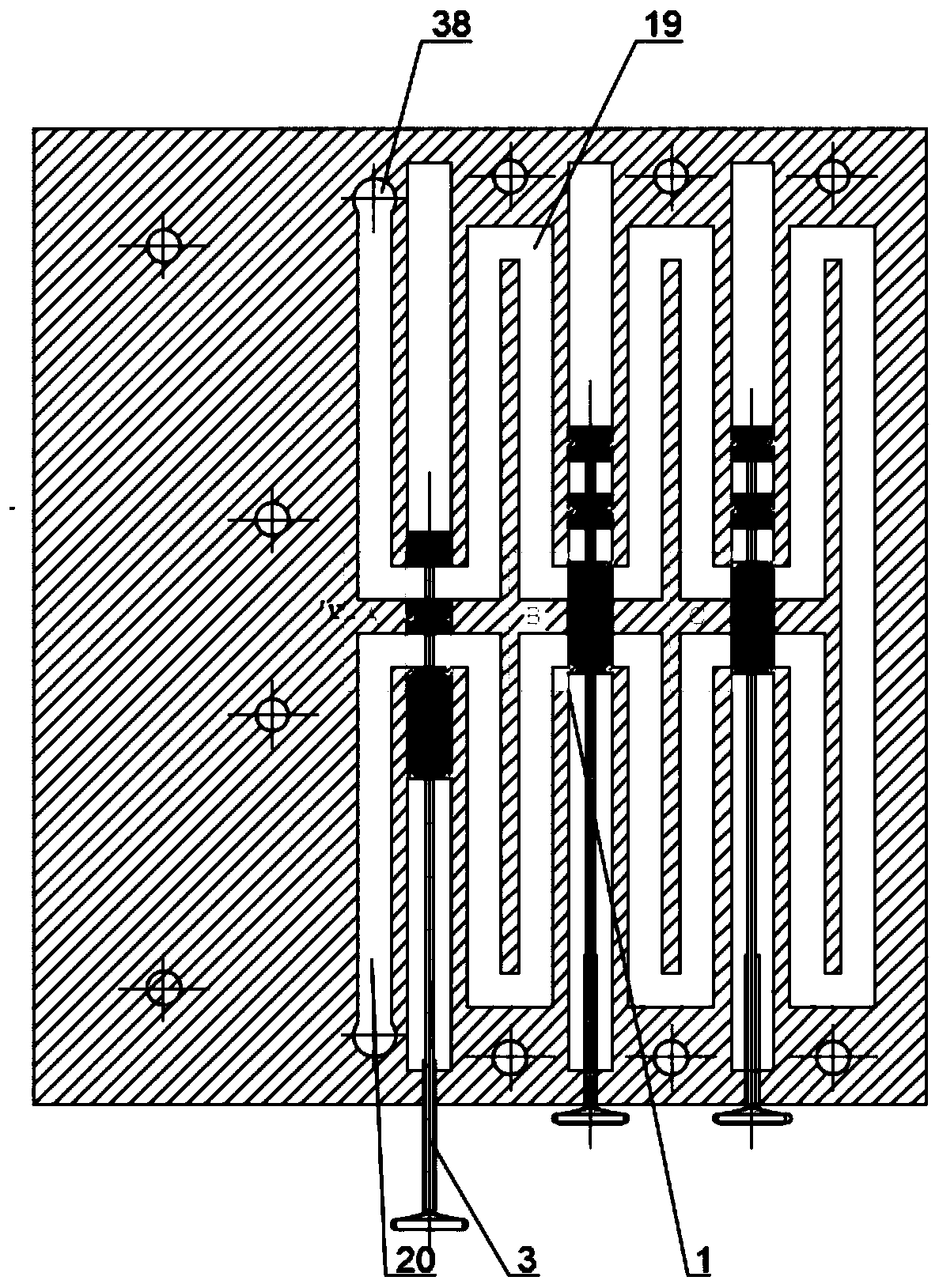

[0034] Such as figure 1 , figure 2 and image 3 As shown, a frequency-adjustable sonic jet oscillator of the present invention is mainly composed of a gas capacity adjustment mechanism 1, a flow channel extender 2, a flow channel adjustment mechanism 3, a flow channel growth adjustment channel 4, an oscillating body 5, and an upper cover 9 And accept pipe 18 to constitute. The whole machine is completely static, and adopts the structure of the combination of the sonic oscillating jet generator, the flow channel growth adjustment mechanism 3 and the receiving tube 18. The wall switching frequency is greatly changed, and then the gas capacity adjustment mechanism 1 and the flow channel adjustment mechanism 3 are combined to fine-tune the Coanda switching frequency, thereby changing the Coanda switching frequency of the jet in a large range. Each growth channel 19 needs a flow channel adjustment mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com