Heat exchanger for motor vehicle and corresponding production method

A technology for heat exchangers and motor vehicles, used in heat exchanger fixing, heat exchange equipment, vehicle components, etc., can solve problems such as unreliable welding, cannot be on the bottom side, and no reliable welding, and achieve increased manufacturing tolerances, Improve quality and improve the effect of micro teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

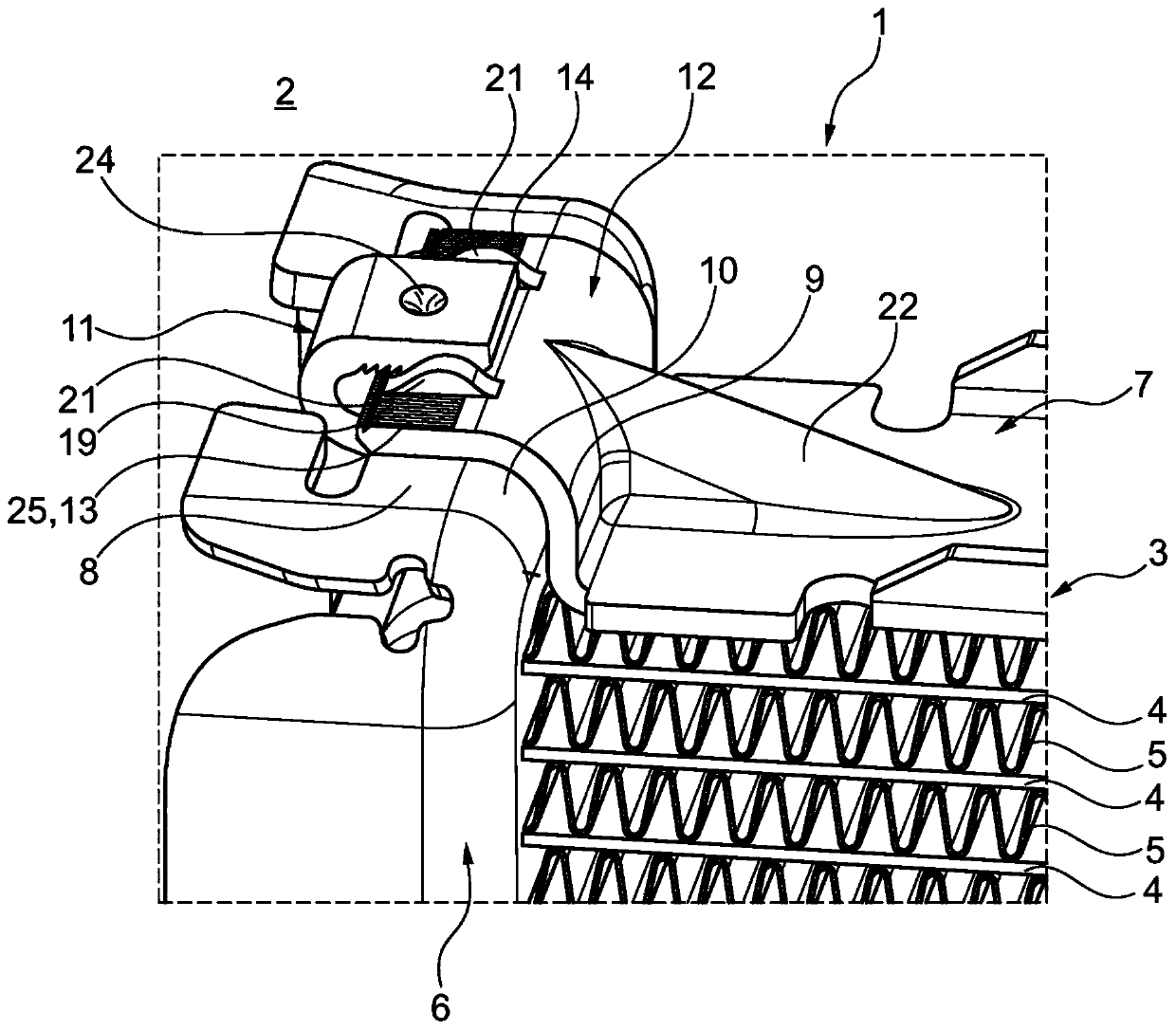

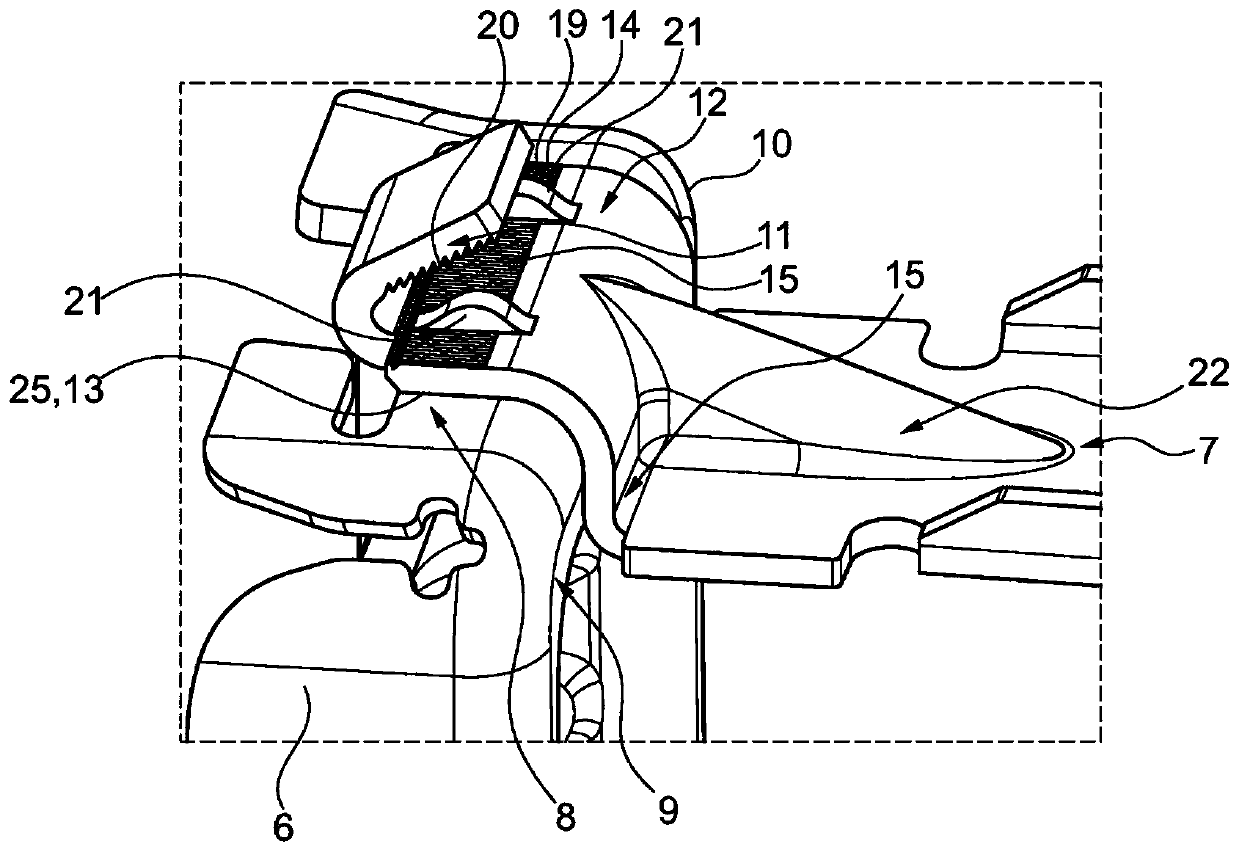

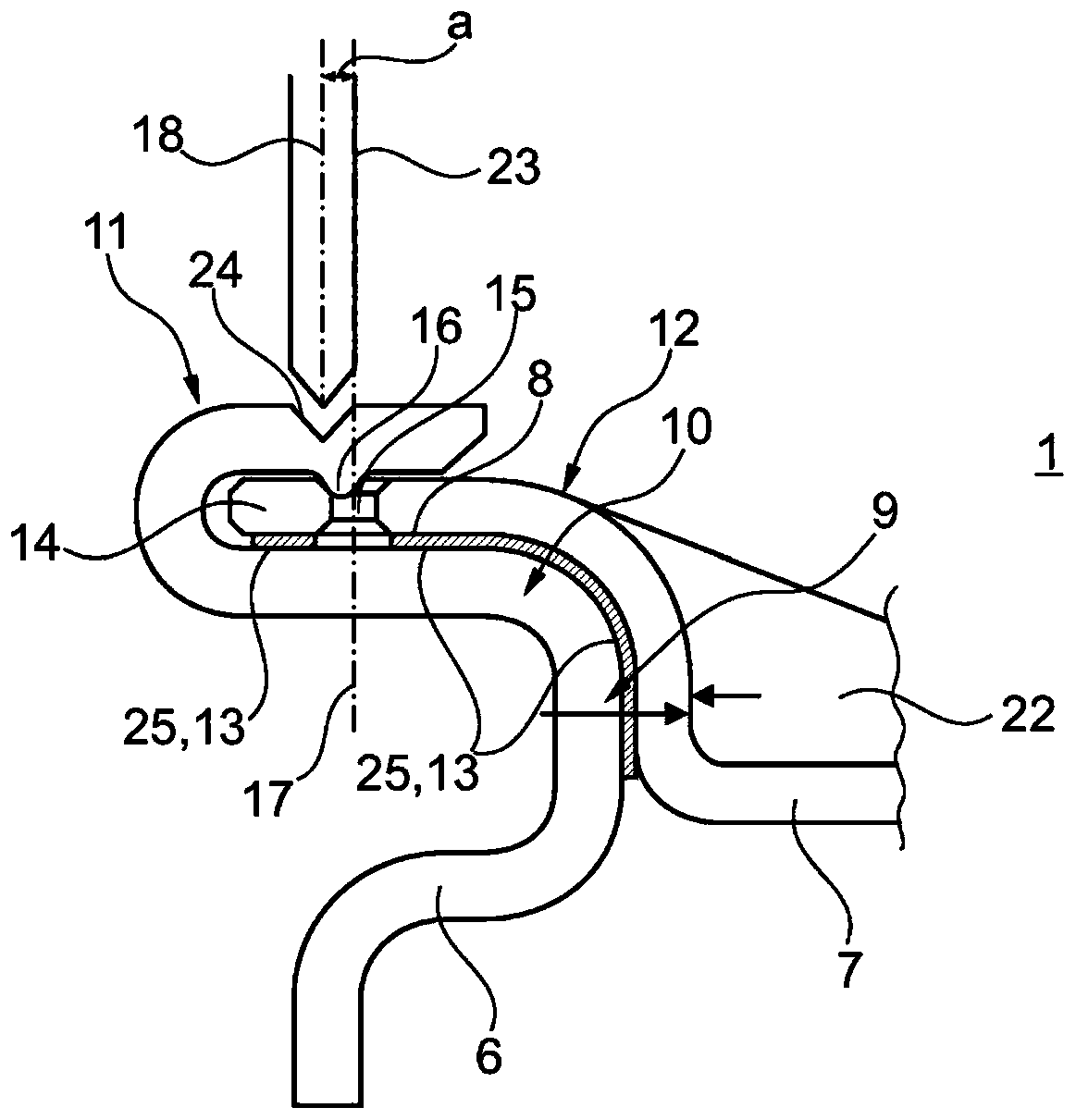

[0019] according to figure 1 , the heat exchanger 1 according to the invention for a motor vehicle 2 has a heat exchanger block 3 with a plurality of parallel flat tubes 4 through which a fluid can flow and a heat exchanger structure arranged therebetween 5, such as corrugated fins. The flat tubes 4 are here tightly accommodated at the longitudinal end sides in the respective associated tube bottom 6 , in particular in passages not shown in the insertion tube bottom 6 , and are tightly welded therein. The heat exchanger block 3 is closed on both sides by a side 7 (see also figure 2 and image 3 ), wherein the respective side portion 7 is mechanically and materially connected to the tube bottom 6 via a welded connection. According to the invention, the tube bottom 6 now has a front side 8 and a bottom side 9 which meet one another via a rounded corner region 10 . The tube bottom 6 has a deformable hook 11 on its front side 8 . The side part 7 has a web 12 on its longitudi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com