Power transformation equipment typical visual defect detection system and method based on edge cloud cooperation

A technology for power transformation equipment and visual defects, which is applied in closed-circuit television systems, televisions, transmission systems, etc., and can solve problems such as low detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

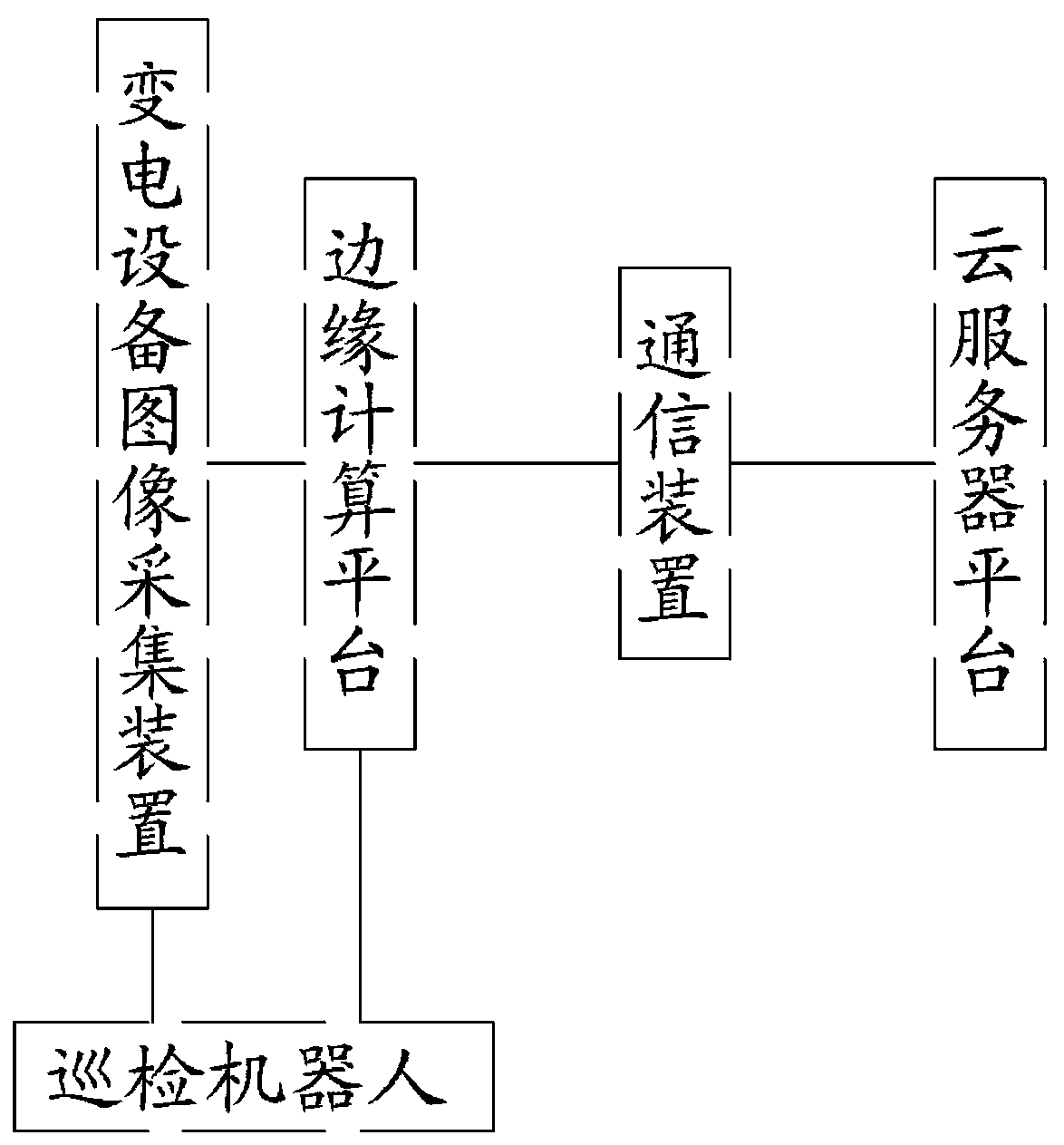

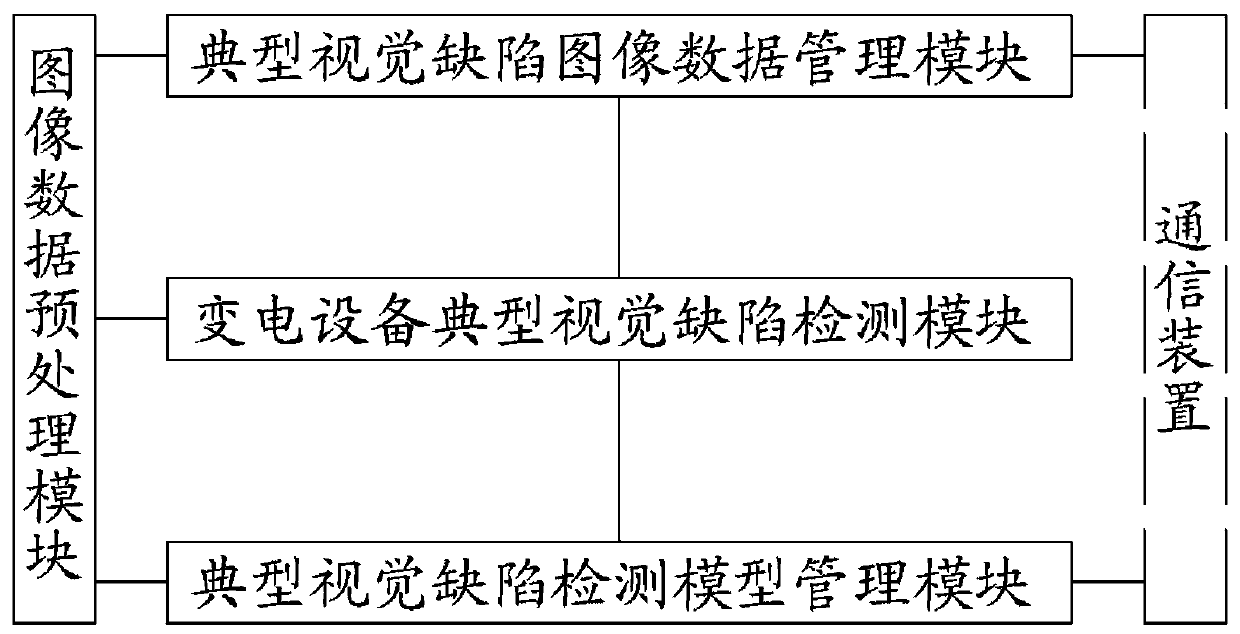

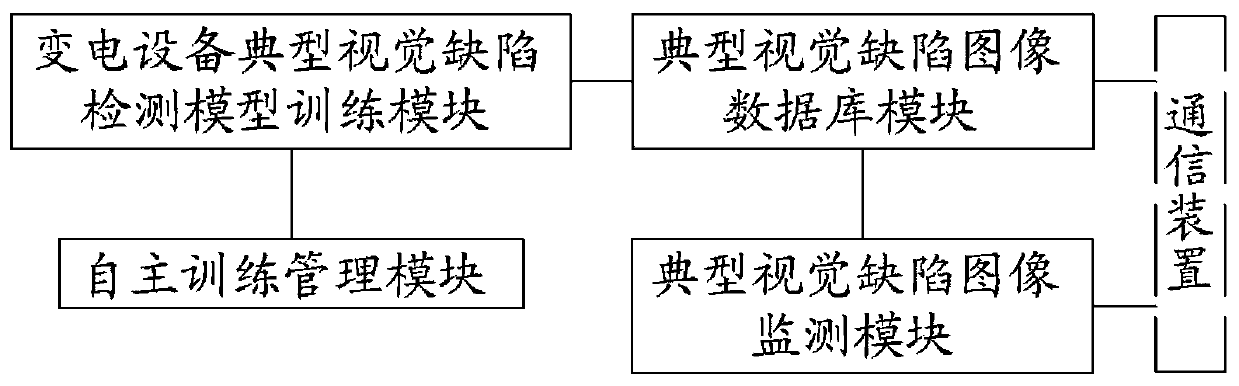

[0033] Such as Figure 1 ~ Figure 3 As shown, the present invention discloses a typical visual defect detection system for substation equipment based on edge-cloud collaboration, including inspection robots, image acquisition devices for substation equipment, edge computing platforms, cloud server platforms, and communication devices. The image data preprocessing module on the computing platform, the typical visual defect detection module of power substation equipment, the typical visual defect image data management module and the typical visual defect detection model management module, and the typical visual defect detection model of power substation equipment running on the cloud server platform Training module, typical visual defect image database module, typical visual defect image detection module and autonomous training management module.

[0034] The image acquisition device of the substation equipment includes a first image acquisition device and a second image acquisi...

Embodiment 2

[0049] Such as Figure 4 As shown, the present invention discloses a typical visual defect detection method for substation equipment based on edge-cloud collaboration, including steps S1 to S5, specifically as follows:

[0050] S1, the image acquisition device of the substation equipment collects the image data of the substation equipment and sends it to the edge computing platform.

[0051] S2. The edge computing platform preprocesses the image data uploaded by the image acquisition device of the substation equipment and sends it to the typical visual defect detection model of the substation equipment. The typical visual defect detection model of the substation equipment detects defects in the image. one step, otherwise go to step S1.

[0052] S3, the edge computing platform marks the defect position and defect type on the image data of the defective electrical substation equipment, and saves the defect image and defect mark data to the storage device of the edge computing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com