Defect detection method based on point cloud information

A defect detection and point cloud information technology, applied in image data processing, instruments, calculations, etc., can solve problems affecting product quality, low detection efficiency, long detection time, etc., to shorten detection time, improve accuracy, prevent The effect of false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] Stamping parts manufacturing is an important part of modern industrial production. Because of its outstanding advantages such as low cost, high efficiency, and good interchangeability, it is widely used in mass production industries such as automobile manufacturing, electrical appliances, and instruments. Improved production quality and production efficiency.

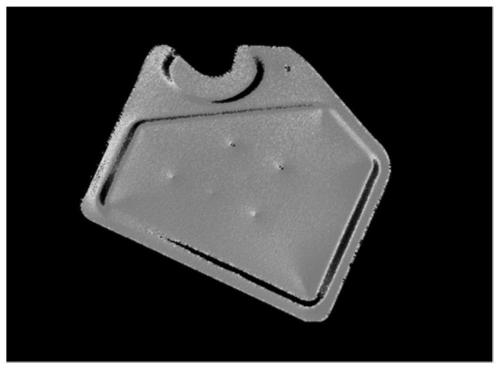

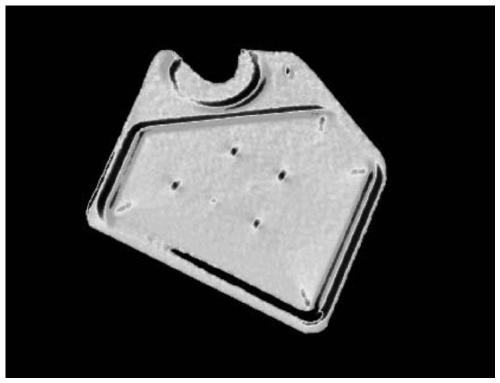

[0035] During the manufacturing and handling process of stamping parts, collisions will occur, resulting in defects such as bulges and pits; this embodiment specifically explains the surface inspection process of stamping parts containing such defects:

[0036] A defect detection method based on point cloud information, comprising the following steps:

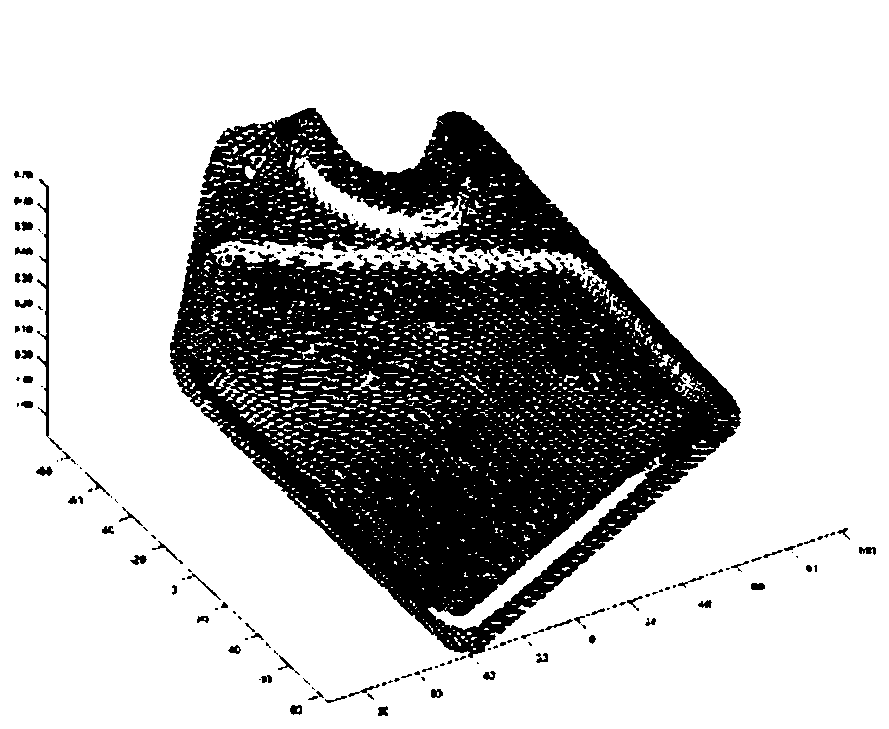

[0037] 1) Perform data processing on the point cloud data on the surface of the stamping part to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com