Elastic deployable helical antenna mechanism

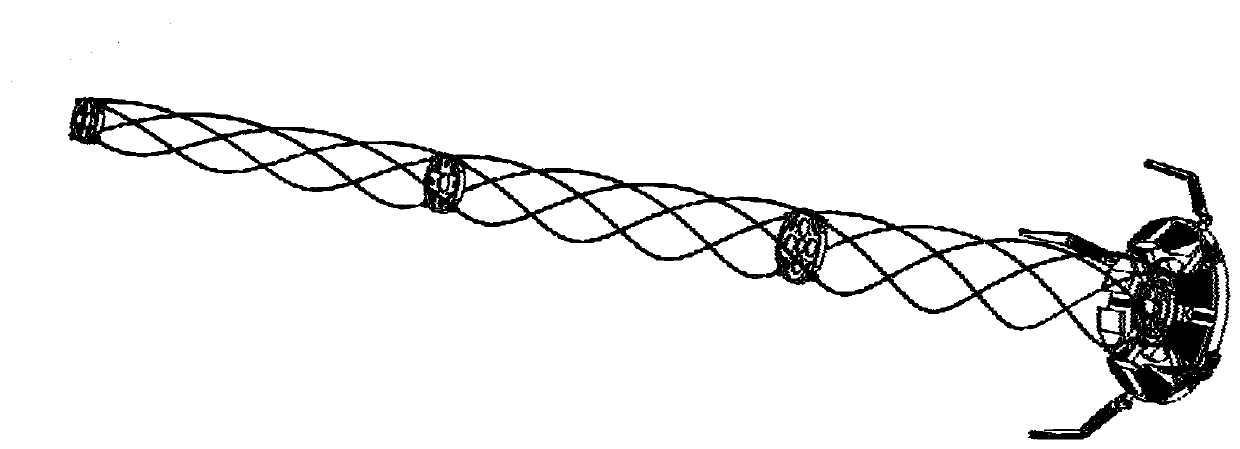

A helical antenna and elastic technology, which is applied in the field of elastic expandable helical antenna mechanisms, can solve the problems of large volume of low-frequency antennas, and achieve the effects of large expansion ratio, small size and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

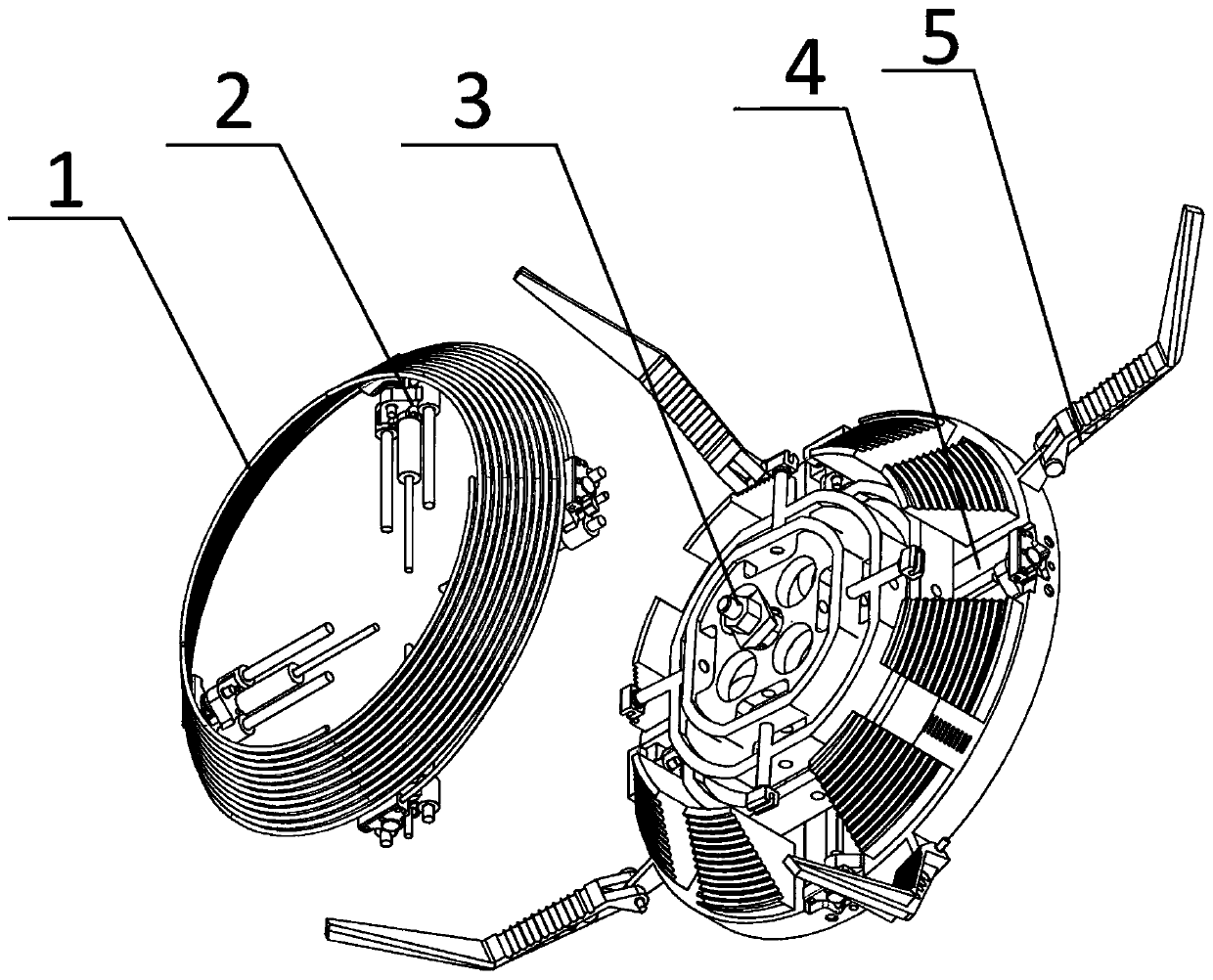

[0029] Specific implementation mode one: refer to figure 1 Describe this embodiment in detail. An elastically expandable helical antenna mechanism described in this embodiment includes: an antenna body 1 and a support base 4;

[0030] The support seat 4 includes a cylindrical shaft 4-1 and a fixed sleeve 4-2, the support seat 4 is processed with a groove 4-4, the cylindrical shaft 4-1 is arranged at the center of the support seat 4, and the cylindrical The axis of the shaft 4-1 is perpendicular to the support seat 4, the fixed sleeve 4-2 is set on the outside of the cylindrical shaft 4-1, the support seat 4 is provided with four grooves 4-4, and the support seat 4 A plurality of pressing devices 5 are arranged in the circumferential direction, and the support base 4 is also provided with four moving devices 2 in the circumferential direction, and the moving devices 2 are arranged in the groove 4-4, and the cylindrical shaft 4-1 is close to the support Seat 4 is processed with...

specific Embodiment approach 2

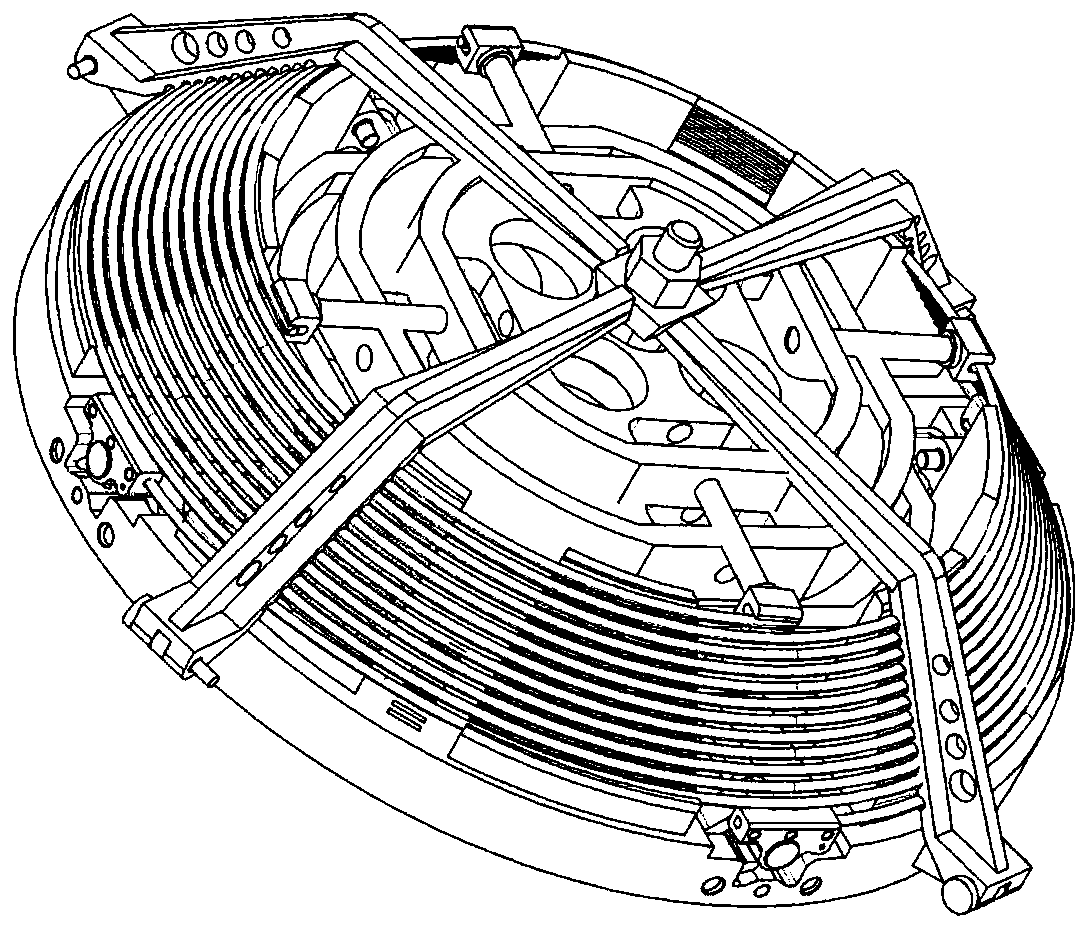

[0038] Specific embodiment 2: This embodiment is a further description of specific embodiment 1. The difference between this embodiment and specific embodiment 1 is that there are multiple auxiliary support plates 6, and the fixing clip 7 on one of the auxiliary support plates 6 It is fixedly connected with one end of the helical antenna; the other auxiliary support plates 6 are arranged between the auxiliary support plate 6 and the support seat 4, and the fixing clips 7 on the other auxiliary support plates 6 hold the helical antenna.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment is a further description of Embodiment 1. The difference between this embodiment and Embodiment 1 is that the compression support 5-1 and the compression arm 5-2 are provided with antennas to fix groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com