Furniture plate production method

A production method and technology for furniture boards, which are applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers, can solve the problems of affecting the sanding effect of the board and the poor positioning effect of the board, and achieve reliable positioning and stability. High, high surface flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for producing a furniture board, comprising the steps of:

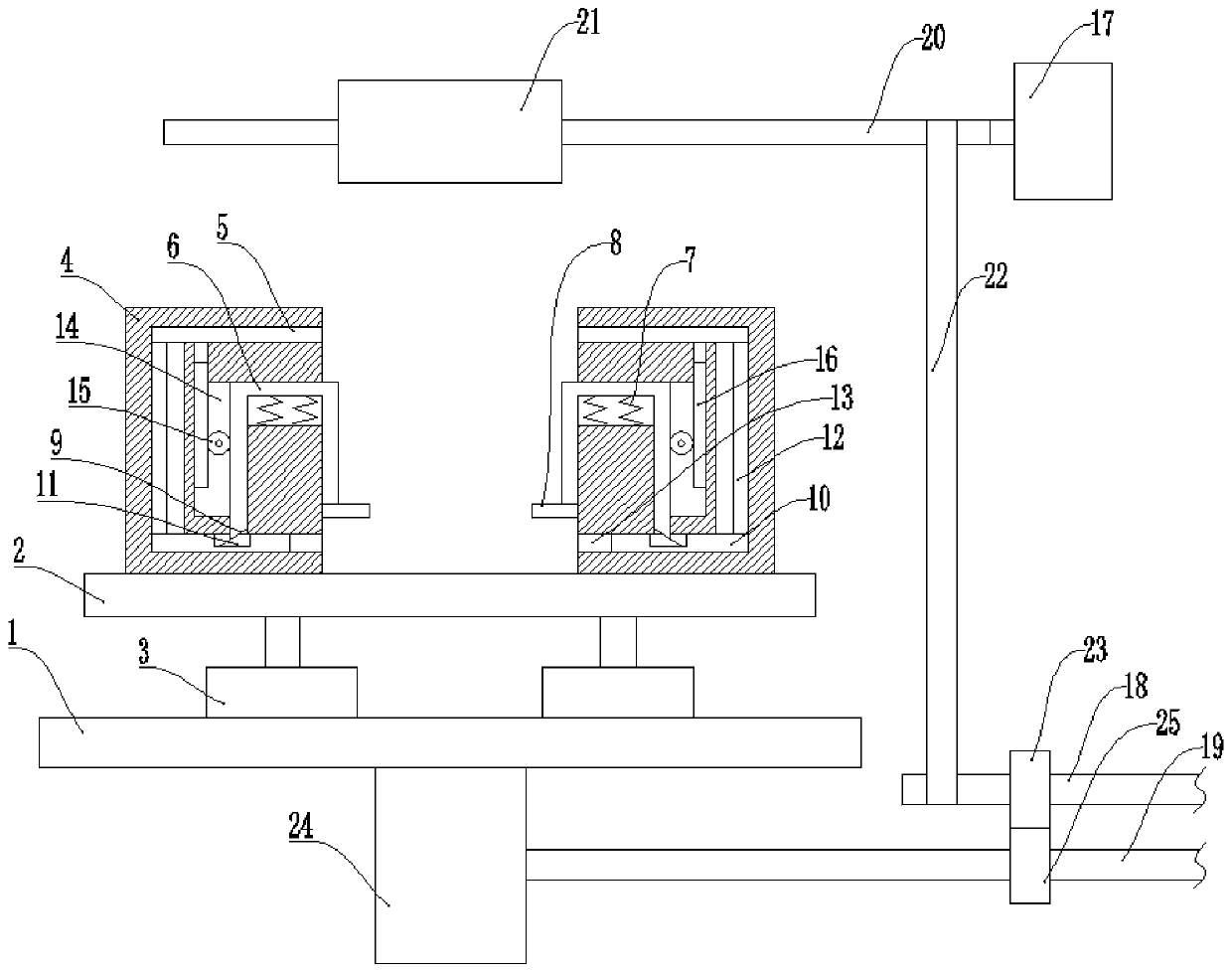

[0036] Step 1, preparation; prepare a number of flat plates, each group of 13 plates, each group of 13 plates is numbered in the order of 1 to 13; prepare sanding equipment, sanding equipment includes machine base, movable table 1 and lifting Platform 2, the movable platform 1 is provided with a driving mechanism for driving the vertical movement of the lifting platform 2; the lifting platform 2 is provided with a clamping mechanism for plate positioning; the machine base is provided with a sanding mechanism for sanding the surface of the plate, And the sanding mechanism is located above the clamping mechanism;

[0037] Step 2, one-time slab forming; 13 plates in a single group are all glued, and then 9 of the plates are selected for cold pressing. The cold pressing time is 52 minutes and the pressure is 11mpa to obtain a primary plate core; for the primary plate core Repair the defects on the board, ...

Embodiment 2

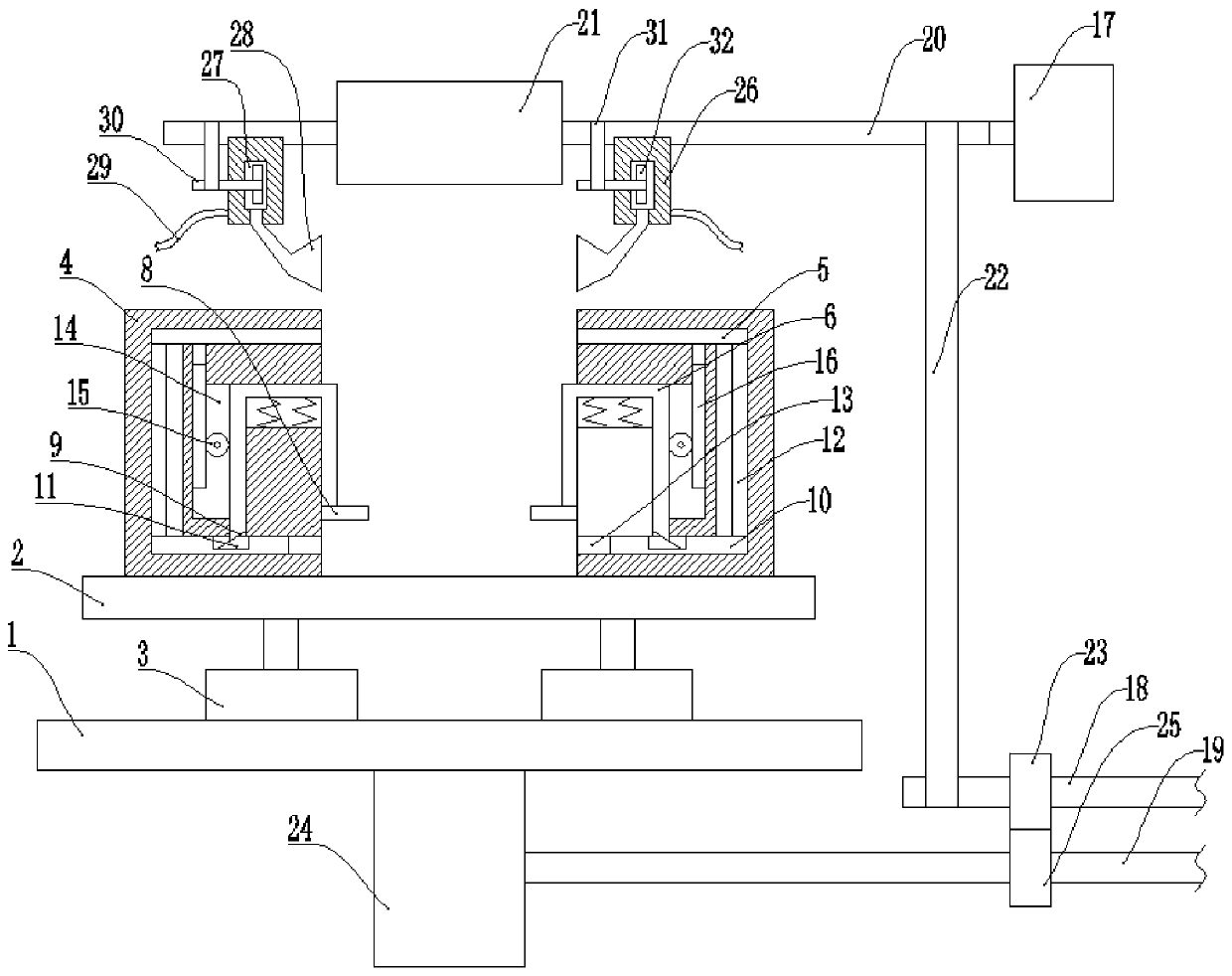

[0051] Basic as attached figure 2 As shown: the structure and implementation of Embodiment 2 are basically the same as Embodiment 1, the difference is that: both sides of the sanding roller 21 on the machine base are fixedly connected with fixed platforms 26, and the fixed platforms 26 are located on the rotating shaft 20 Below; the top of the fixed table 26 has a top groove against the rotating shaft 20 .

[0052] A negative pressure chamber 27 is opened in the fixed table 26, and the negative pressure chamber 27 is communicated with a negative pressure pipe 28 facing the direction of the gap between the two vertical blocks 4, and the fixed table 26 is connected with a recovery pipe 29 communicated with the negative pressure chamber 27; The side wall of the fixed table 26 is rotatably connected with a linkage shaft 30 extending into the negative pressure chamber 27, and the linkage shaft 30 and the rotating shaft 20 are sleeved with a second belt 31; the linkage shaft 30 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com