Radio frequency copper detector and automatic correction system and detection method and automatic correction method

A radio frequency and automatic technology, applied in the field of etching process and etching process system, can solve the problems of inaccurate detection results, inaccurate results, waste of resources and costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical means adopted by the present invention to achieve the intended creation purpose are further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

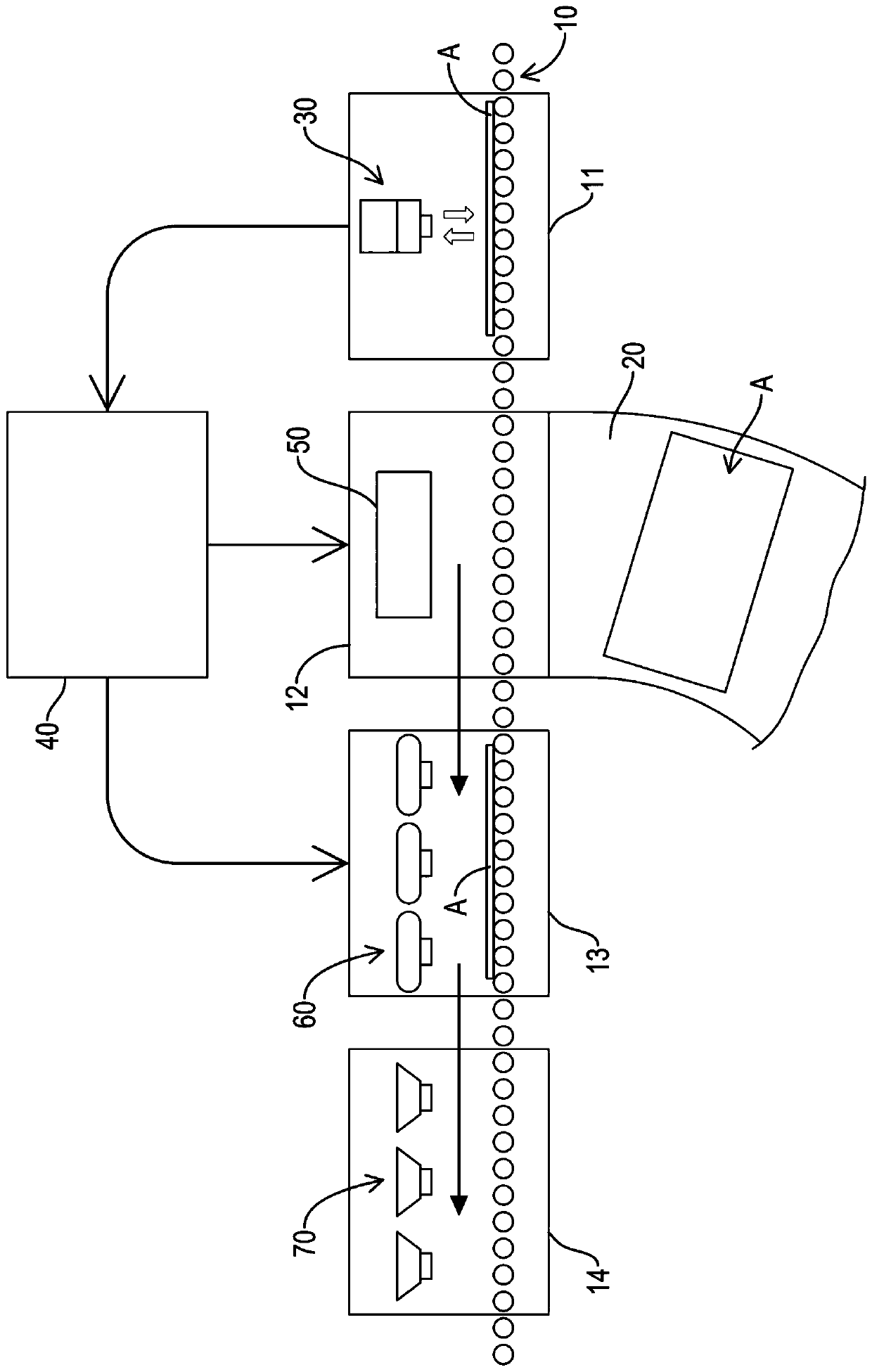

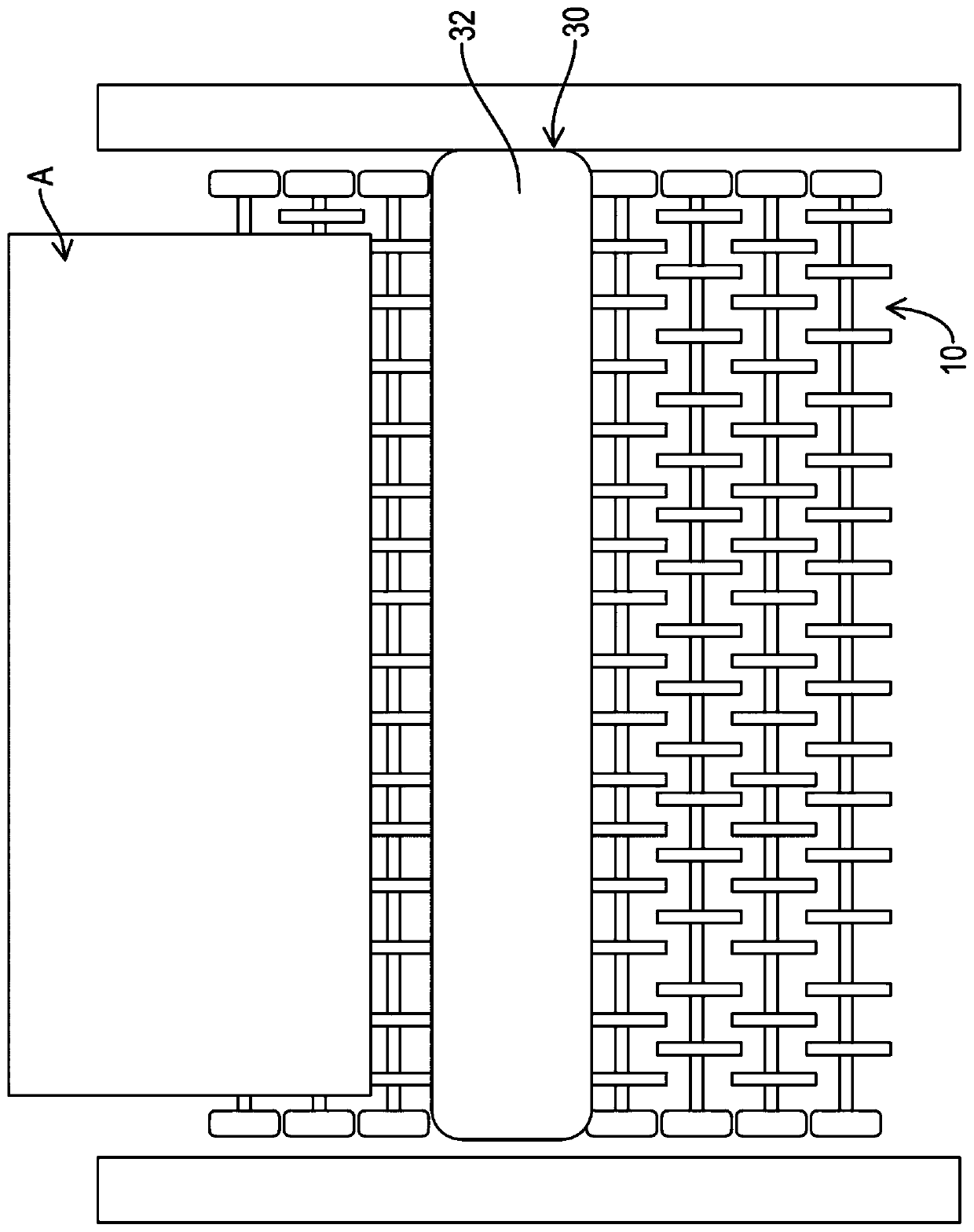

[0047] see figure 1 and figure 2 As shown, the substrate thickness detection and automatic correction system of the present invention is used to detect and correct the thickness of the copper plating on the surface of a substrate A or the uniformity of the copper plating thickness on the surface. The substrate thickness detection and automatic correction system includes a transport track 10 , a removal track 20 , a radio frequency copper measuring instrument 30 , a computing unit 40 , a removal device 50 , a pre-etching device 60 and a main etching device 70 .

[0048] The conveying track 10 includes a detection area 11 , a discrimination area 12 , a correction area 13 and an etching area 14 which are sequentially connected. The transport track 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com