Static-pressure rotation table constant linear speed running oil film lubricating performance detection method

A technology of constant linear velocity and static pressure turntable, which can be applied to lubricating parts, engine lubrication, flow characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

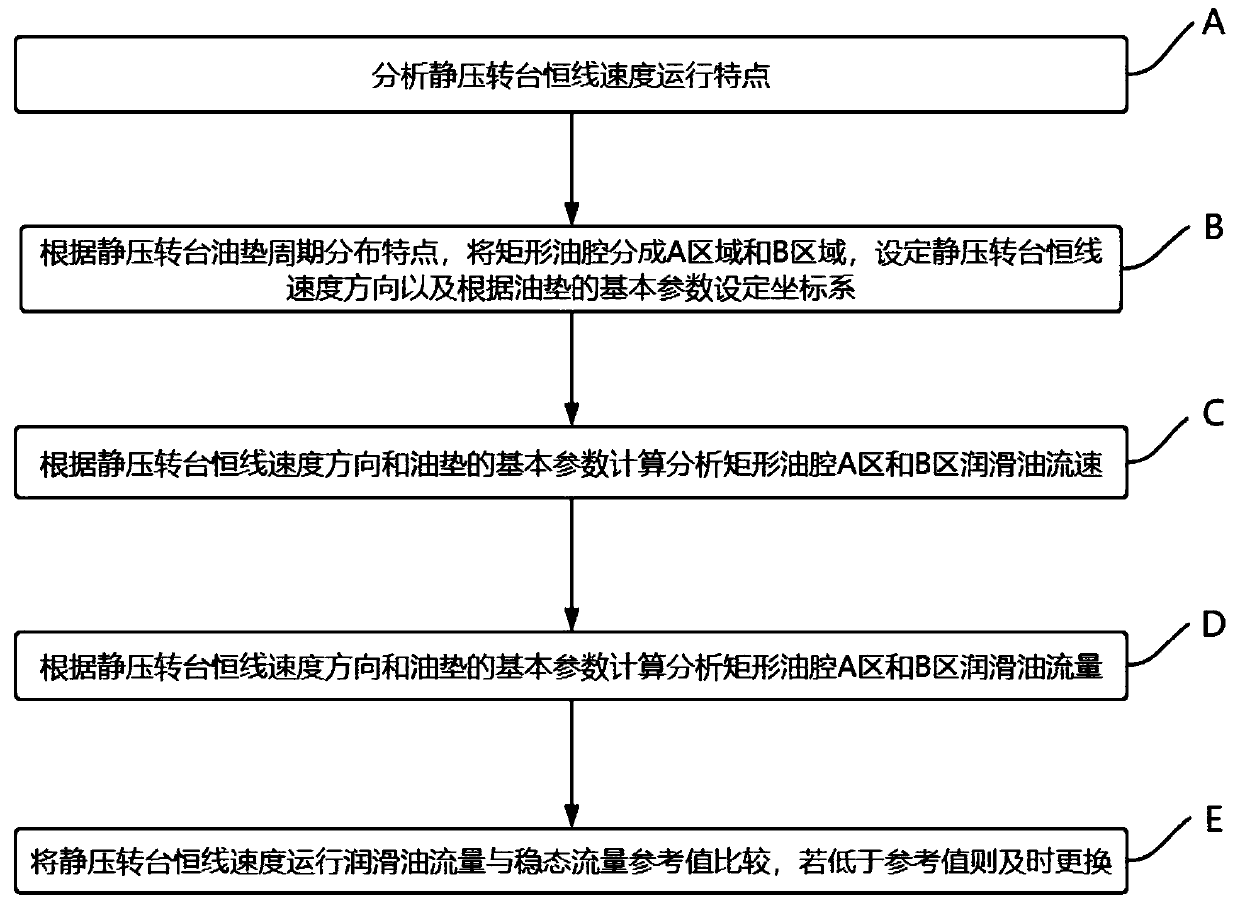

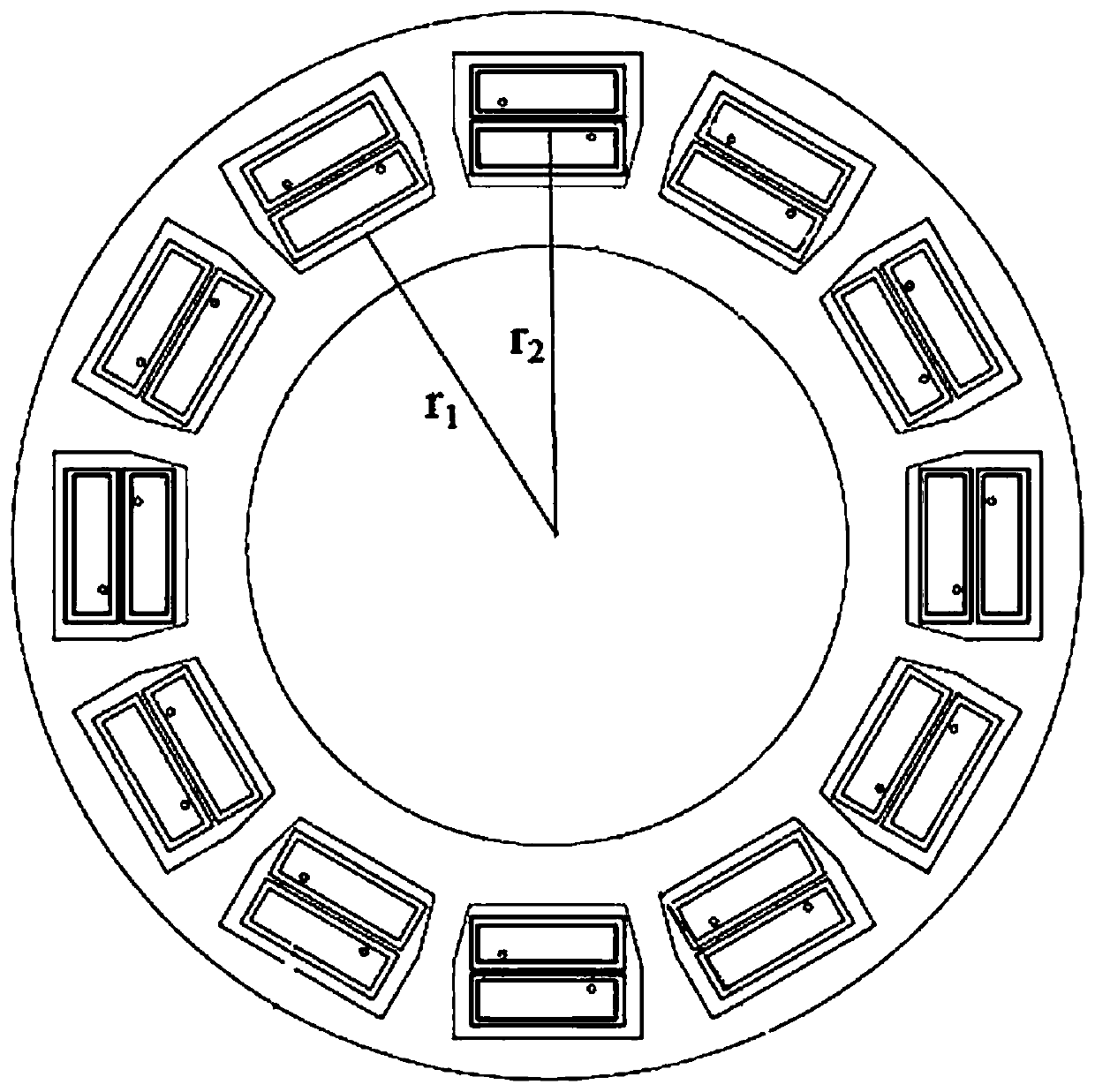

[0043] Such as figure 1 As shown, the present invention is a method for detecting the oil film lubrication performance of a static pressure turntable operating at a constant linear velocity. By theoretically analyzing the lubrication characteristics of a double rectangular cavity hydrostatic thrust bearing turntable operating at a constant linear velocity, the mechanism of the oil film flow in the gap is analyzed. Deduce the unsteady gap flow velocity equation and the instantaneous flow equation, including the following steps:

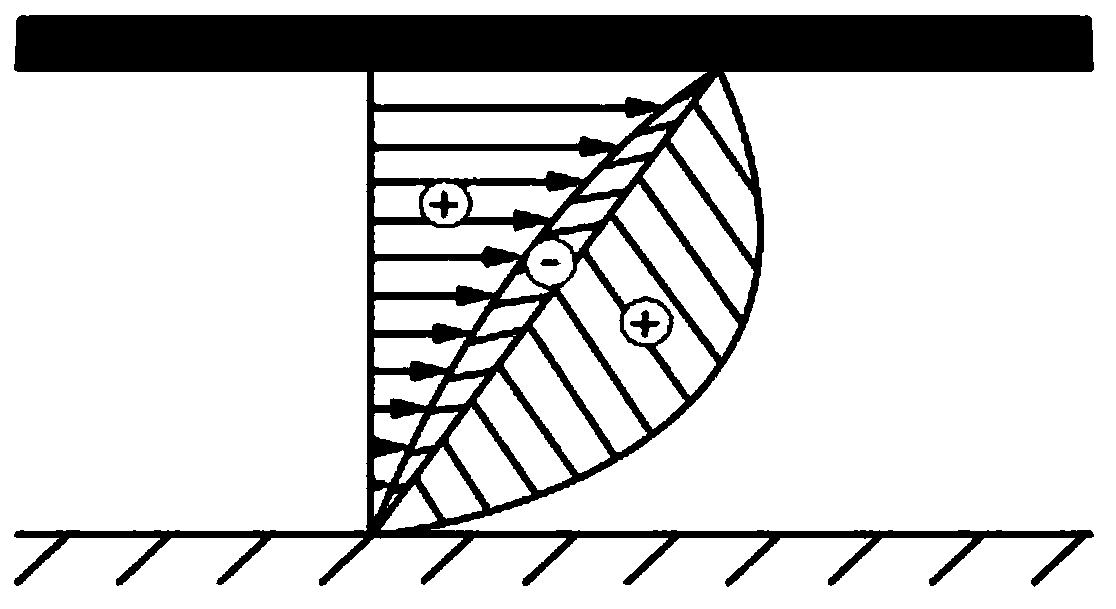

[0044] Step A: Analyze the operating characteristics of the static pressure turntable at constant linear velocity. The velocity field of the gap flow with acceleration boundary is composed of three parts: one is the flow caused by the pressure difference between the inlet and outlet, and the velocity field is distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com