Rotary go-no-go gauge that completes ball-end hanging ring detection at one time

A ball head hanging ring, rotating technology, applied in the direction of measuring gauges, plug gauges, etc., can solve the problems of high labor intensity, slow inspection speed, low operation efficiency of inspectors, and improve the comfort of use, inspection speed, inspection speed, etc. Efficiency improvement, easy to use and quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

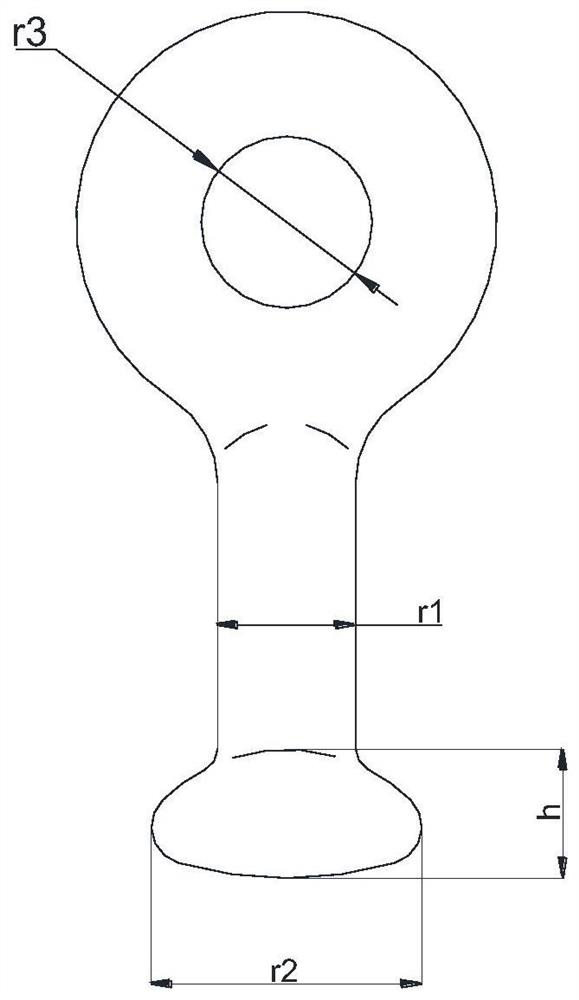

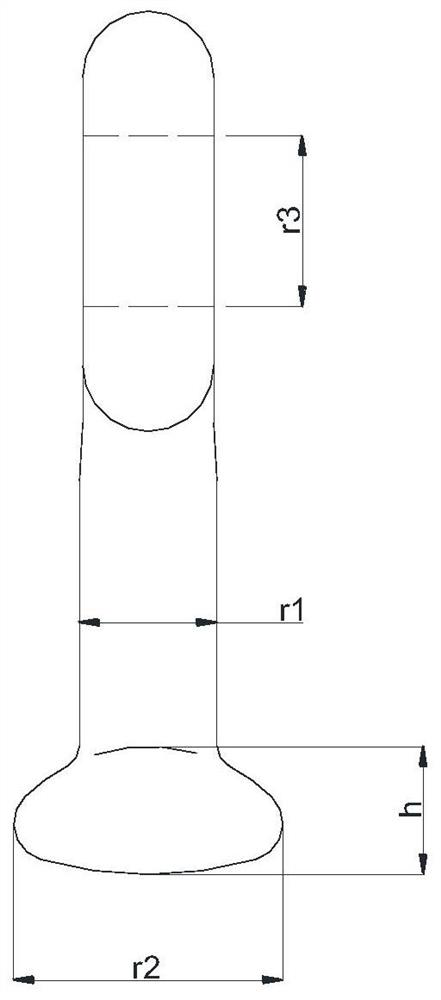

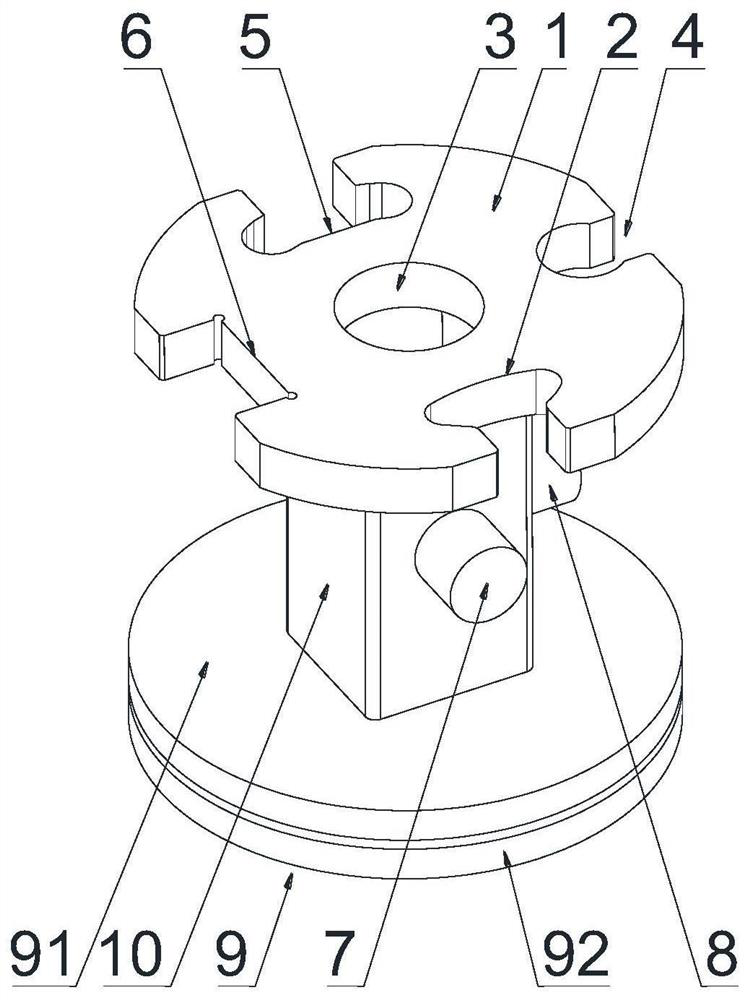

[0062] Such as the drawings of the book Figure 3 - Figure 8 As shown, the present embodiment includes a mounting hole diameter regulatory regulatory or means of indirectly coupled to the regulatory plate 1;

[0063] The ball high-rod radius detection groove 2, the ball head spherical scrip 4, the ball speed detecting groove 5, and the ball head spherical detection groove 5 and the ball head spherical detection groove 5 Signaling slot 6; wherein the ball head sprulte detecting hole 3 is located at the center position of the plate 1, the ball high rod passage 4, the rod stop detection slot 4, the ball head ball high and temporary detection slot 5 And the ball spherical stop detection groove 6 is distributed in the direction of 1 circumferential direction;

[0064] The mounting pore diameter gauge includes mounting aperture 7 and a mounting hole stop 8.

[0065] Such as the drawings of the book Figure 11 As shown, the ball high-rod passage detection slot, the balloon high and constan...

Embodiment 2

[0081] The present embodiment is substantially consistent with the first embodiment, and the different point is to secure the mounting hole pass 7, and the mounting hole stopper 8 is fixed to the upper rotating disk 91 fixed to the hollow column 10. The mounting hole stopper 7 is attached to the upper rotating disk 91, and the detection of a single-end hanging ring can also be achieved. The mounting hole pillar 7, the mounting hole stopper 8 is more implementation, for example, for example, in the mounting hole stopper, the mounting hole pillar is disposed on the top surface, and the screw and the upper rotating plate 91 are fixed, etc. .

Embodiment 3

[0083] Such as the drawings of the book Figure 9- Figure 10 As shown, the present embodiment includes a mounting hole diameter regulatory regulatory or means of indirectly coupled to the regulatory plate 1;

[0084] The ball high-rod radius detection groove 2, the ball head spherical scrip 4, the ball speed detecting groove 5, and the ball head spherical detection groove 5 and the ball head spherical detection groove 5 Signaling slot 6; wherein the ball head sprulte detecting hole 3 is located at the center position of the plate 1, the ball high rod passage 4, the rod stop detection slot 4, the ball head ball high and temporary detection slot 5 And the ball spherical stop detection groove 6 is distributed in the direction of 1 circumferential direction;

[0085] The mounting pore diameter gauge includes mounting aperture 7 and a mounting hole stop 8.

[0086] Such as the drawings of the book Figure 11 As shown, the ball high-rod passage detection slot, the balloon high and constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com