Nondestructive testing method for sealing degree of cigarette small box package without system errors

A technology for eliminating system and non-destructive testing, which is applied in fluid tightness testing, measuring devices, testing of machine/structural components, etc. It can solve problems such as large system errors, small differences, and no system error elimination proposed to achieve accuracy Detect and evaluate and eliminate the effects of systematic errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

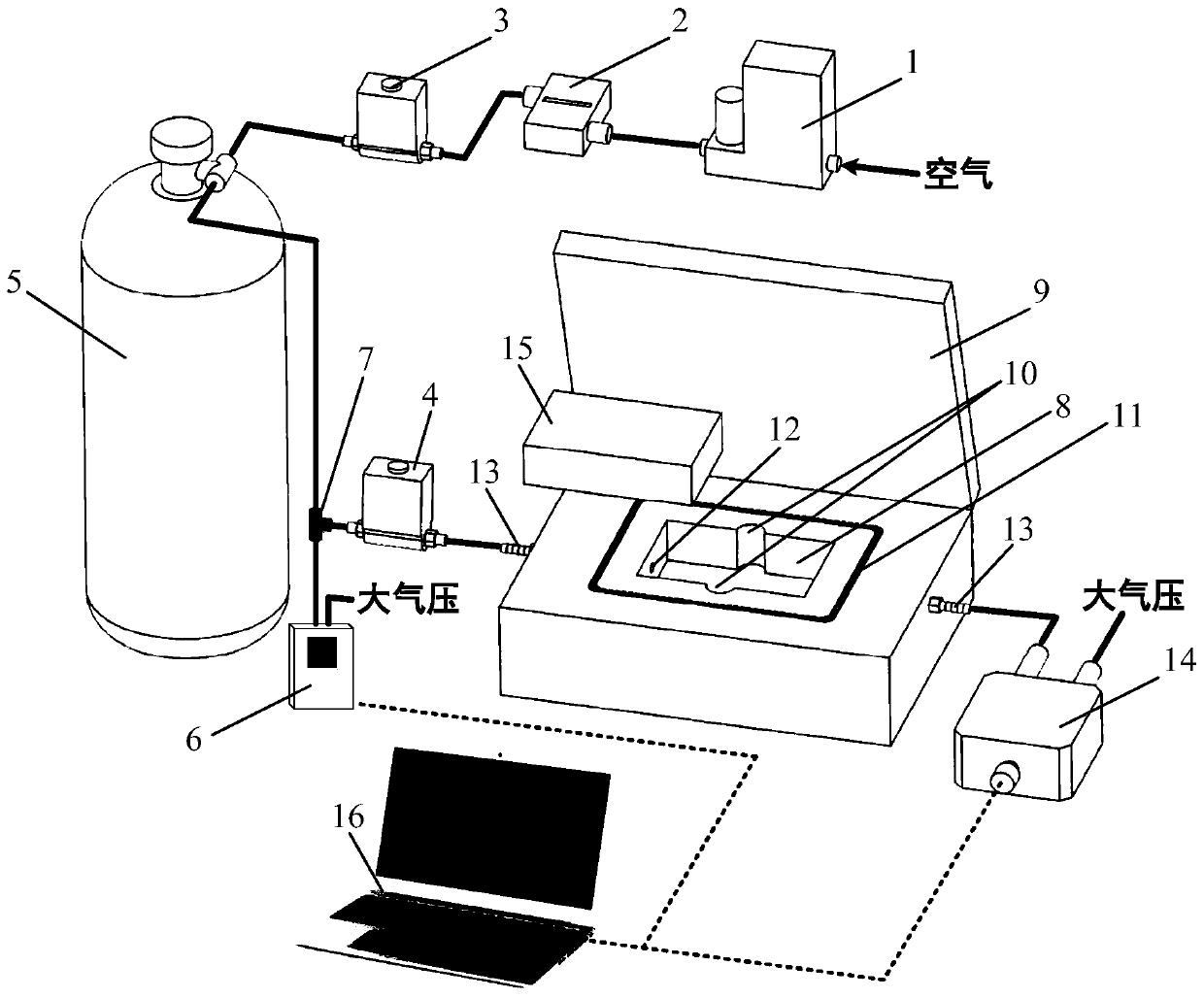

[0036] The illustrative and non-limiting embodiments of the present invention will be described in detail below with reference to the accompanying drawings, and the method for non-destructive testing of the sealing degree of small cigarette packs according to the present invention will be further described.

[0037] According to the method for non-destructively testing the airtightness of small cigarette packs of the present invention, a tightness detection device is used to detect samples of small cigarette packs. The sealing degree detection device comprises a negative pressure generator, a detection box and a computer which are connected in sequence. The detection box includes a box body and a cover plate that is connected to the box body and can be opened and closed relative to the box body. The box body is provided with a storage cavity and two opposite side walls of the storage cavity. through holes to allow air to enter and exit the storage cavity.

[0038] Specificall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap