Test equipment of truck or automobile clutch bearings

A test equipment and clutch technology, applied in the direction of mechanical bearing testing, etc., to achieve the effect of simple structure, reliable test and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

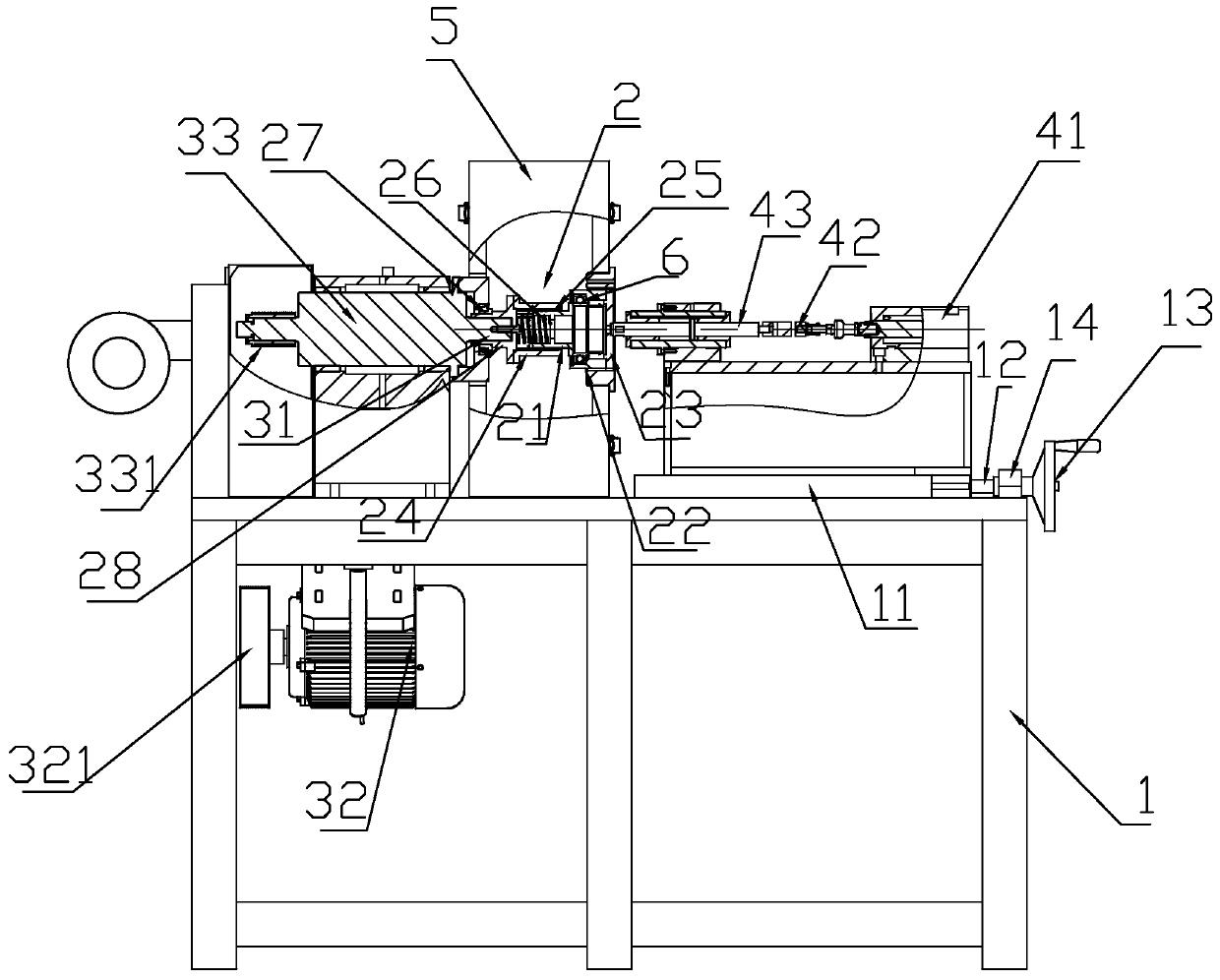

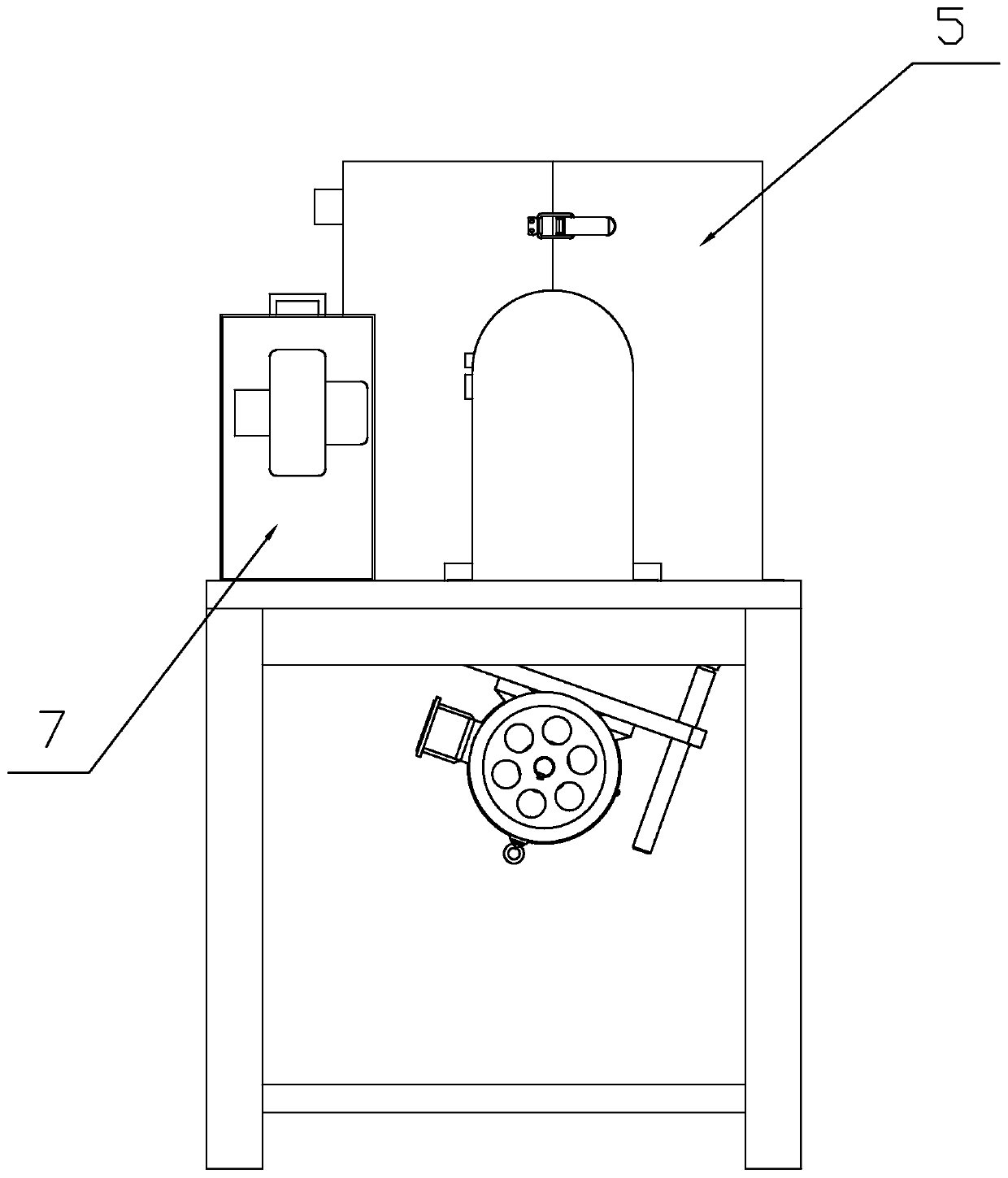

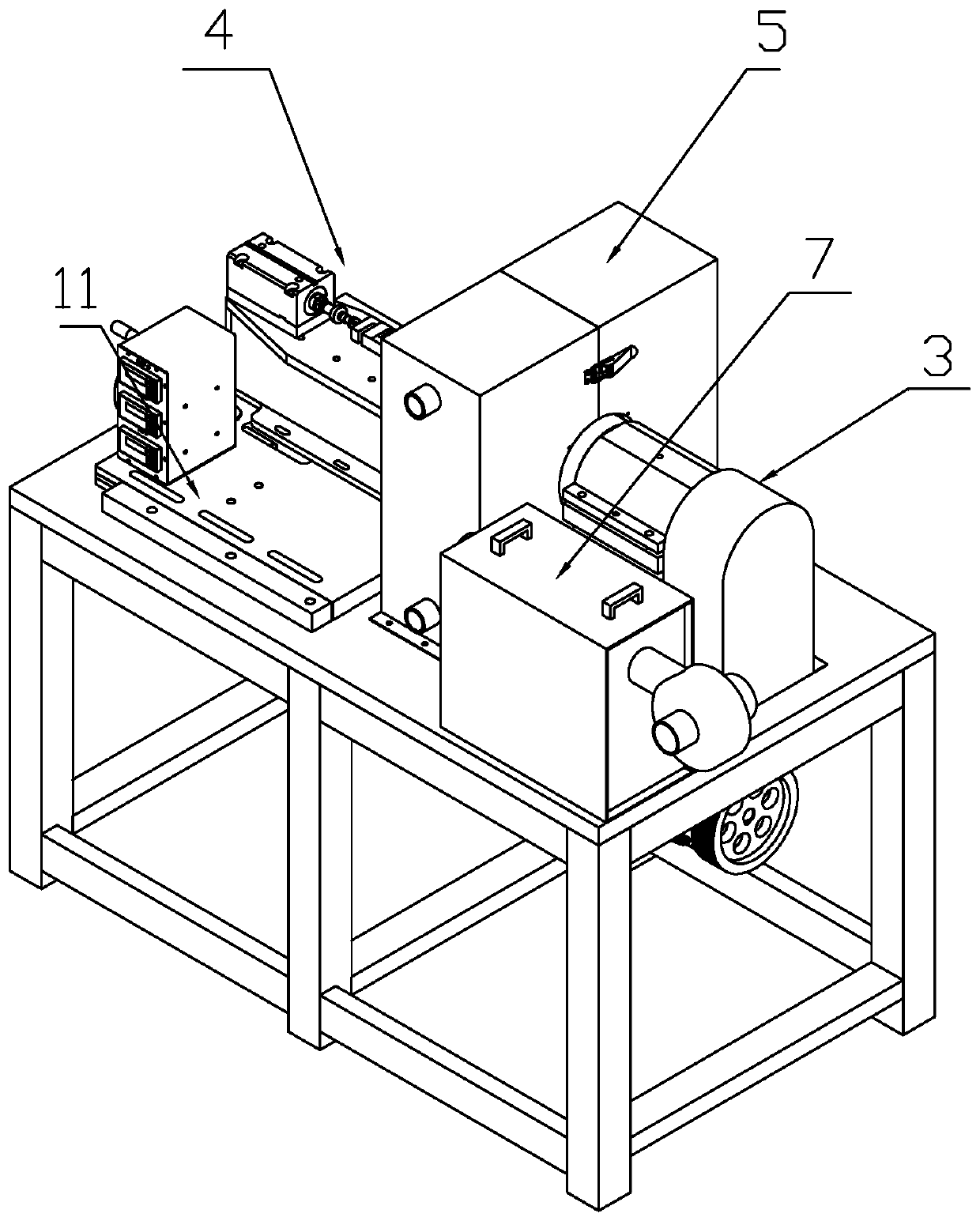

[0023] Specific examples of the present invention Figure 1-3 As shown, a truck or automobile clutch bearing test equipment includes a frame 1. The frame 1 is equipped with an imitation clutch 2, a driving mechanism 3, a release bearing action operating mechanism 4, and a temperature control box 5. The imitation clutch 2 is placed in a temperature control box 5. The imitation clutch 2 includes a rotating loading tool and a pre-tightening force mechanism. The pre-tightening force mechanism is located between the rotating loading tool and the drive mechanism 3. The drive mechanism 3 The output end 31 is connected to the rotary loading tooling through a pretensioning mechanism, the rotary loading tooling includes a simulated flywheel 21 connected with the pretensioning mechanism, a clutch disc 22 for mounting the bearing 6 to be tested, and a release bearing action operating mechanism 4 The connecting transition disc 23, the bearing 6 to be tested is mounted on the clutch disc 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com