Workpiece anti-counterfeiting method based on part surface image matching

A surface image and component technology, applied in the field of workpiece anti-counterfeiting based on component surface image matching, can solve problems such as difficult detection of bearings, bearing damage, and difficult detection of bearings, and achieve reduced anti-counterfeiting costs, high anti-counterfeiting security, and improved robustness. sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

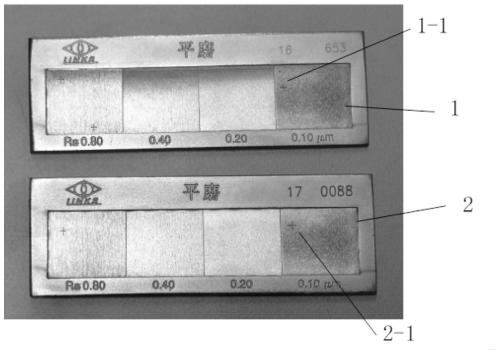

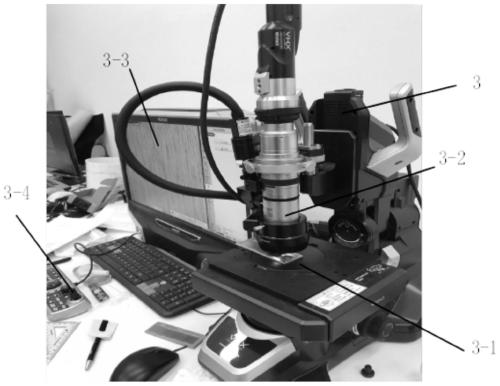

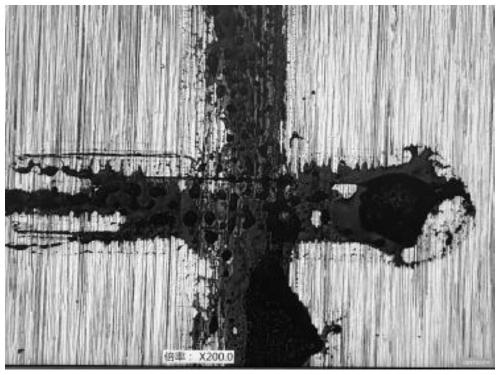

[0093] In this example, in figure 1 Part 1 and Part 2 are used as sample 1 and sample 2. Sample 1 and sample 2 are areas with a roughness of 0.1 μm in the common surface roughness comparison sample. Under naked eye observation, the surfaces with uniform roughness are very similar . figure 2 Among them, 3 is the image acquisition hardware - the digital microscope of Keyence VHX 5000 on sale, which can realize automatic focusing and automatic image stitching. The resolution of the collected single image is 1200pixels×1600pixels, and the maximum resolution after splicing can reach 20000pixels×20000pixels.

[0094] Concrete anti-counterfeit identification method of the present invention is realized by the following steps:

[0095] Step 1. Sample pretreatment:

[0096] exist figure 1 Randomly select a small area on the parts 1 and 2 in the box, and mark the 1-1 area and 2-1 area with the word '+', as the anti-counterfeiting detection area mark.

[0097] Step 2. Image acquisit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com