Ethylene-vinyl acetate copolymer anti-counterfeiting film and preparation method thereof

A technology of vinyl acetate copolymerization and vinyl acetate, applied in the field of ethylene-vinyl acetate copolymer anti-counterfeiting film and its preparation, can solve the problems of not having anti-counterfeiting function, increasing processing procedures, affecting product appearance, etc., to achieve authenticity identification and traceability , good binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1~A40

[0044] Embodiments A1~A40 and comparative examples B1~B4: preparation of anti-counterfeiting masterbatch

[0045] Weigh the carrier resin, fluorescent powder, coding substances and additives according to the proportions shown in Table 1~5, pour them into a high mixer and mix evenly, melt them in a twin-screw extruder at 200~300°C, extrude and granulate , to prepare anti-counterfeiting masterbatch.

[0046]

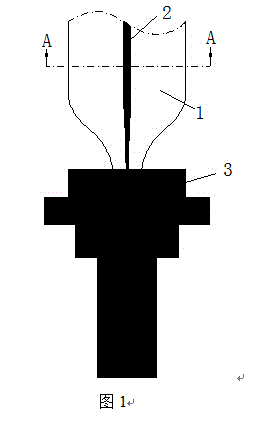

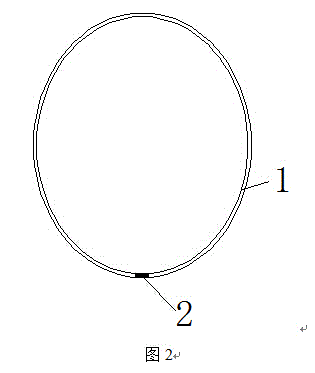

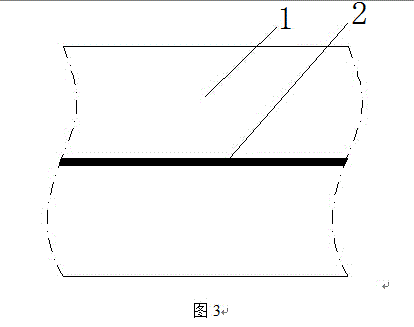

[0047] Examples 1-40 and Comparative Examples 1-6: Preparation of ethylene-vinyl acetate copolymer anti-counterfeiting film

[0048] A kind of preparation method of ethylene-vinyl acetate copolymer anti-counterfeiting film, its raw material formula is as shown in table 6~10, and its preparation method comprises the following steps:

[0049]Weigh each component by weight, and use two large and small extruders to extrude ethylene-vinyl acetate copolymer, processing aids and the anti-counterfeiting masterbatch prepared in Tables 1 to 5 to the co-extrusion head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com