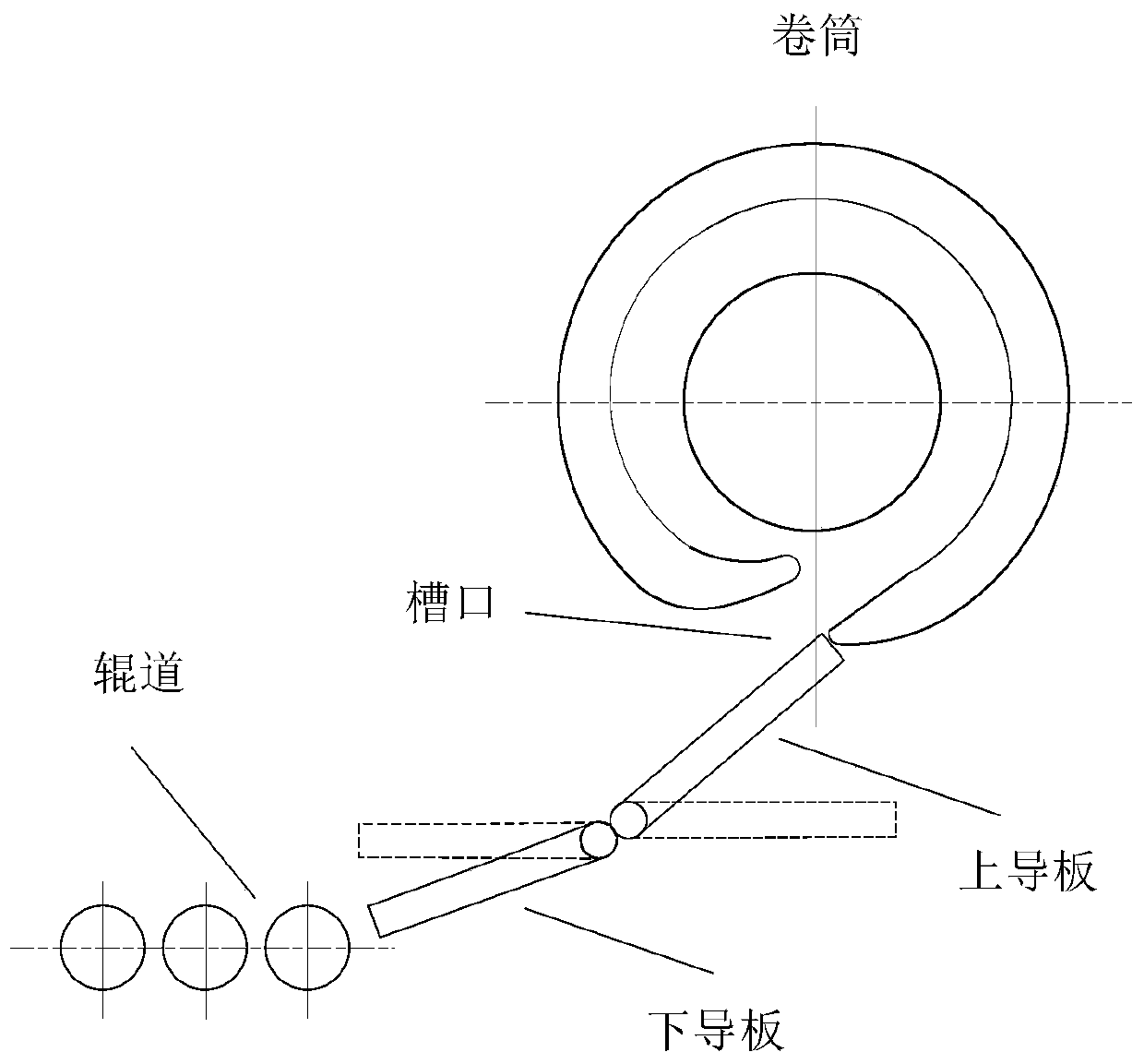

Control method for precise positioning of drum notch of steekle mill

A technology for precise positioning and steckel rolling mills, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of increasing the difficulty of precise positioning control of notches, achieves improved positioning control accuracy, simple and high-efficiency implementation Effect of precision positioning control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The program is implemented on a 1780mm coil rolling line in a factory, and the specific implementation steps are as follows:

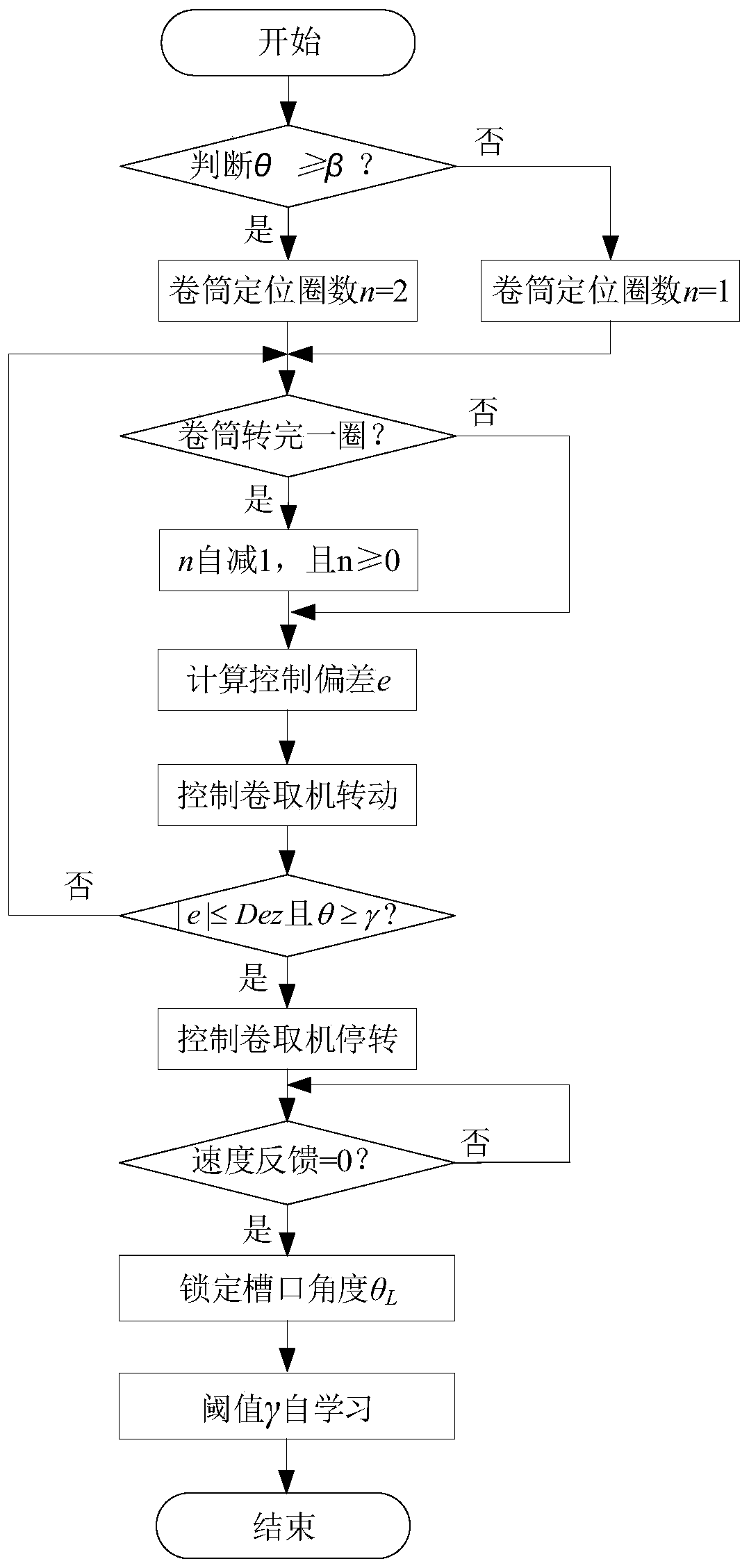

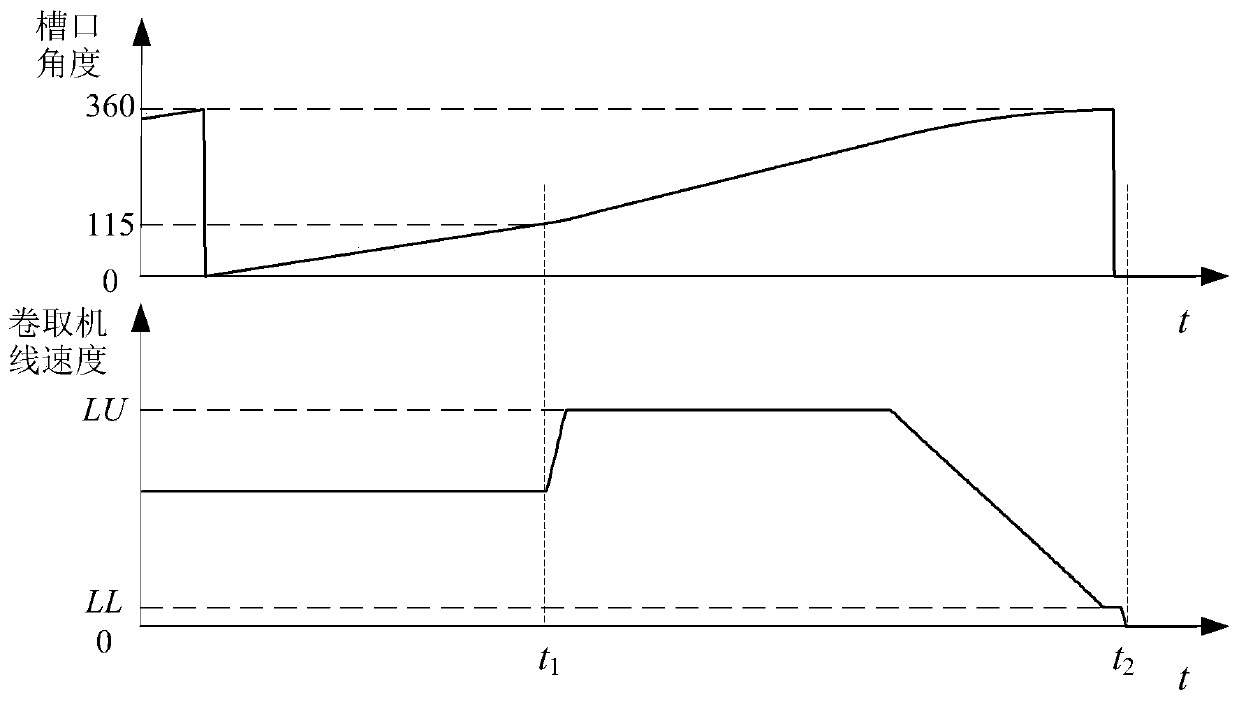

[0052] Step 1: At the moment when the positioning of the reel notch is started, first judge whether the automatic positioning is completed when the reel rotates the first turn or the positioning is completed when the reel turns the second turn according to the value of the angle feedback value θ of the reel notch. The basis for judging the number of turns n required to complete positioning is:

[0053]

[0054] In the formula, β is the threshold for judging the number of positioning circles;

[0055] Among them, the calculation formula of β is: LU=1.0m / s, K=0.1.

[0056] Step 2: Calculate the control deviation e according to the feedback value θ of the notch angle of the reel and the number of turns n required for the notch to complete the positioning. The calculation formula is: e=360n-θ;

[0057] Step 3: Start the positioning control of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com