Movable powder metallurgy forming equipment

A technology for powder metallurgy and molding equipment, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., and can solve the problems of inconvenient movement of molding equipment and difficulty in taking out finished products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

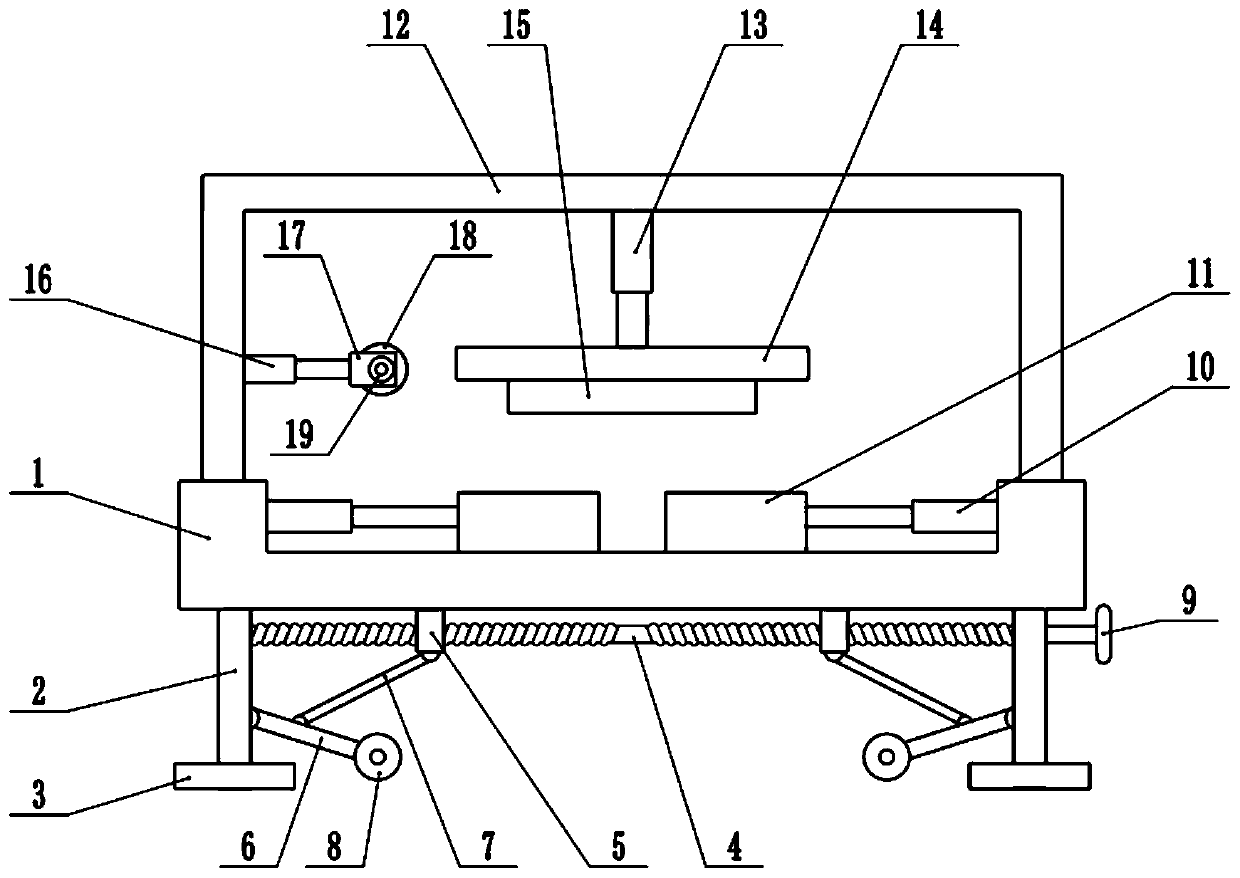

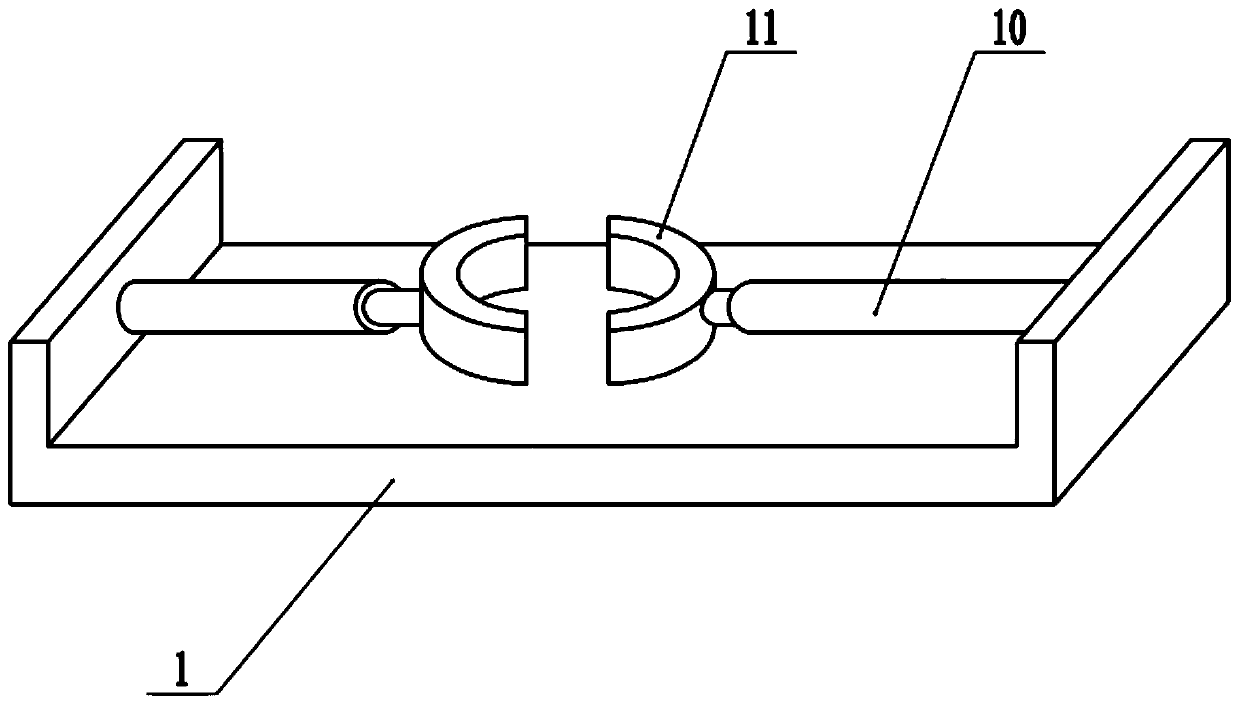

[0022] see Figure 1-3 , in an embodiment of the present invention, a mobile powder metallurgy molding equipment, including a workbench 1, a support plate 2, a fixed frame 12, a lifting plate 14 and an upper mold 15, the bottom of the workbench 1 is fixedly connected with a support plate 2, supporting There are two boards 2, which are symmetrically arranged left and right. The bottom of the support plate 2 is fixedly connected with a base plate 3 to keep the device stable. The bottom of the workbench 1 is provided with a two-way screw rod 4, and the two ends of the two-way screw rod 4 are connected to the support plate respectively. 2 rotating connection, the right end of the two-way screw rod 4 is equipped with a turntable 9, the two-way screw rod 4 is covered with a slider 5, there are two sliders 5, left and right symmetrically arranged, the lower surface of the slider 5 is hinged with a connecting rod 7, The side wall of the support plate 2 is hinged with a movable rod 6, ...

Embodiment 2

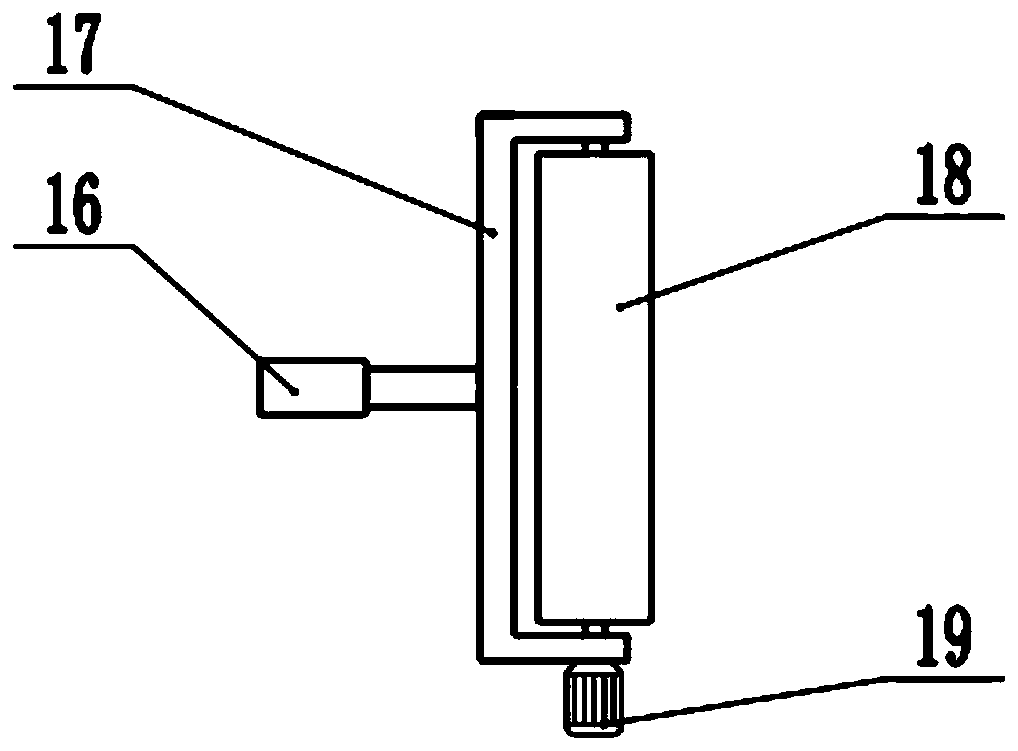

[0024] On the basis of Embodiment 1, a cleaning mechanism is also installed on the side wall of the fixed mount 12, and the cleaning mechanism includes a third telescopic mechanism 16, a mounting frame 17, a cleaning roller 18 and a cleaning motor 19, and the side wall of the fixed mount 12 is fixedly connected with The 3rd expansion mechanism 16, the 3rd expansion mechanism 16 is electro-hydraulic telescopic cylinder, the extension end of the 3rd expansion mechanism 16 is fixedly connected with mounting frame 17, and the interior rotation of mounting frame 17 is connected with cleaning roller 18, and the surface of cleaning roller 18 Bristles are distributed, and the outer side wall of the mounting frame 17 is fixedly connected with a cleaning motor 19. The shaft extension end of the cleaning motor 19 is connected with the end of the cleaning roller 18, and the cleaning motor 19 is started to drive the cleaning roller 18 to rotate. When the lower surface of the mold 15 is clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com