Method for preparing metal matrix composite under different composite pressures in high-throughput manner

A composite material and metal-based technology, which is applied in the field of preparing metal-based composite materials under different composite pressures, can solve problems such as the inability to achieve high-throughput preparation, and achieve the effects of shortening sampling time, saving costs, and halving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

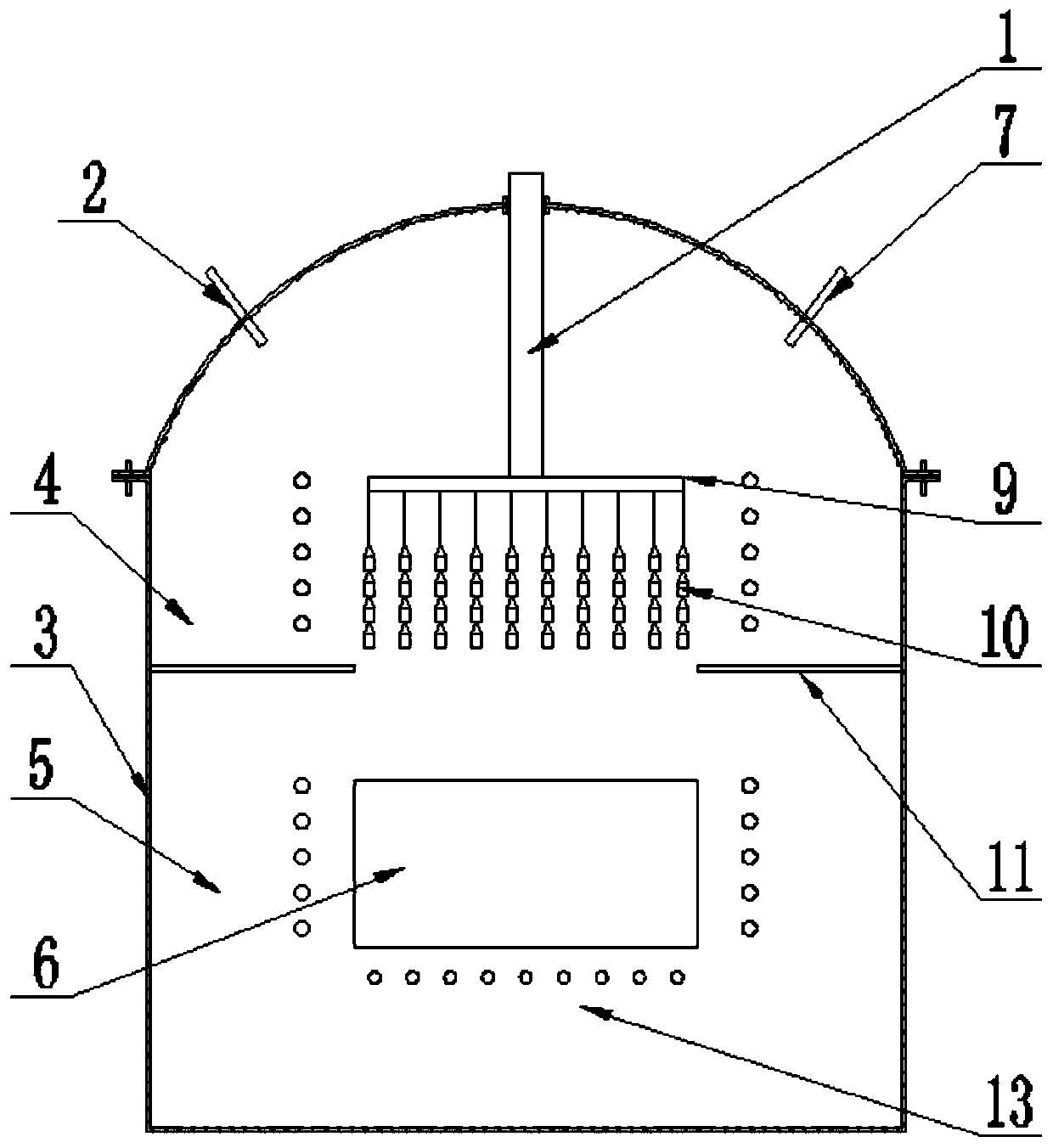

[0023] Specific Embodiment 1: In this embodiment, the method for high-throughput preparation of metal matrix composites under different composite pressures is carried out by using a high-throughput preparation device for metal matrix composites. The specific steps are:

[0024] 1. Preparation:

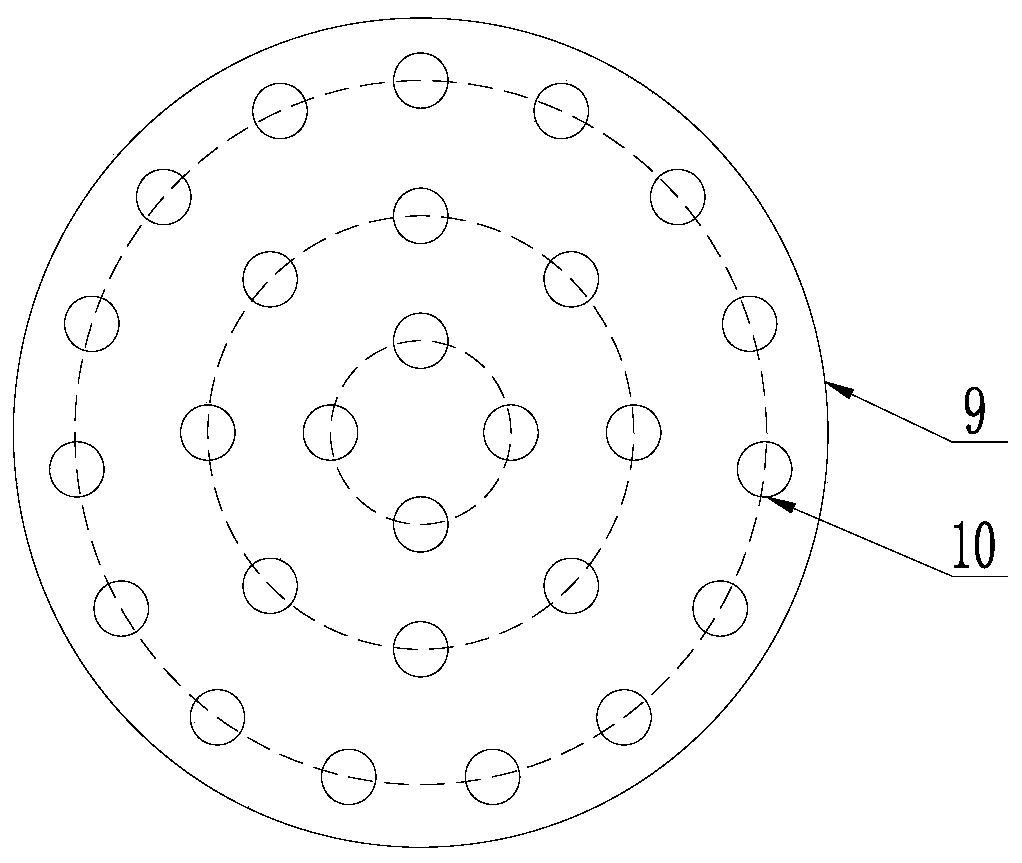

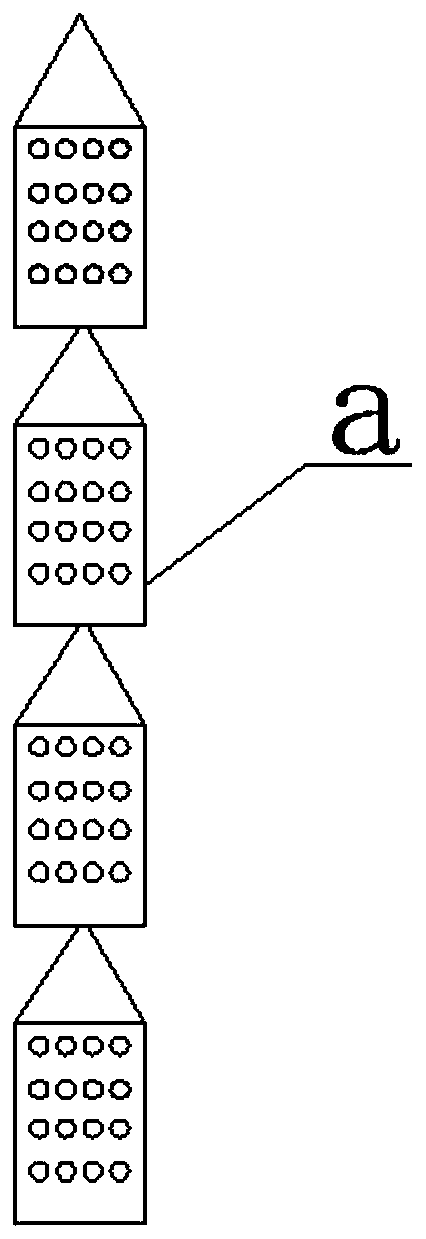

[0025] A plurality of tandem preforms 10 are concentrically hoisted on the lower surface of the preform mounting plate 9, and the crucible 6 is placed in the melting zone 5 between the plurality of tandem preforms 10 and the crucible heating zone 13, in the crucible 6 Filling with matrix metal; filling all molds in each tandem preform 10 with the same composite reinforcement, filling different tandem preforms 10 with different composite reinforcements;

[0026] 2. Prefabricated body adhesive removal

[0027] Close the inflatable tube 7, connect the exhaust tube 2 to a vacuum device to evacuate the furnace body 3, and at the same time use the electric heating element in the preheating ...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 2, the exhaust pipe 2 is connected to a vacuum device to evacuate the furnace body 3 to a vacuum degree of 10-1000 Pa.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment differs from Embodiment 1 in that: the descending rate of the lifting rod 1 in Step 4 is 0.01 mm / s˜2.0 mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com