Plasma body electrolytic deposition method of aluminium alloy cglinder body inner wall ceramic coating and its device

A technology of plasma electrolysis and ceramic coating, applied in the direction of anodic oxidation, phosphating, etc., can solve the problems of increasing the weight of the aluminum alloy cylinder body and complex process, and achieve the effect of solving the problem of wear resistance, simple process and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

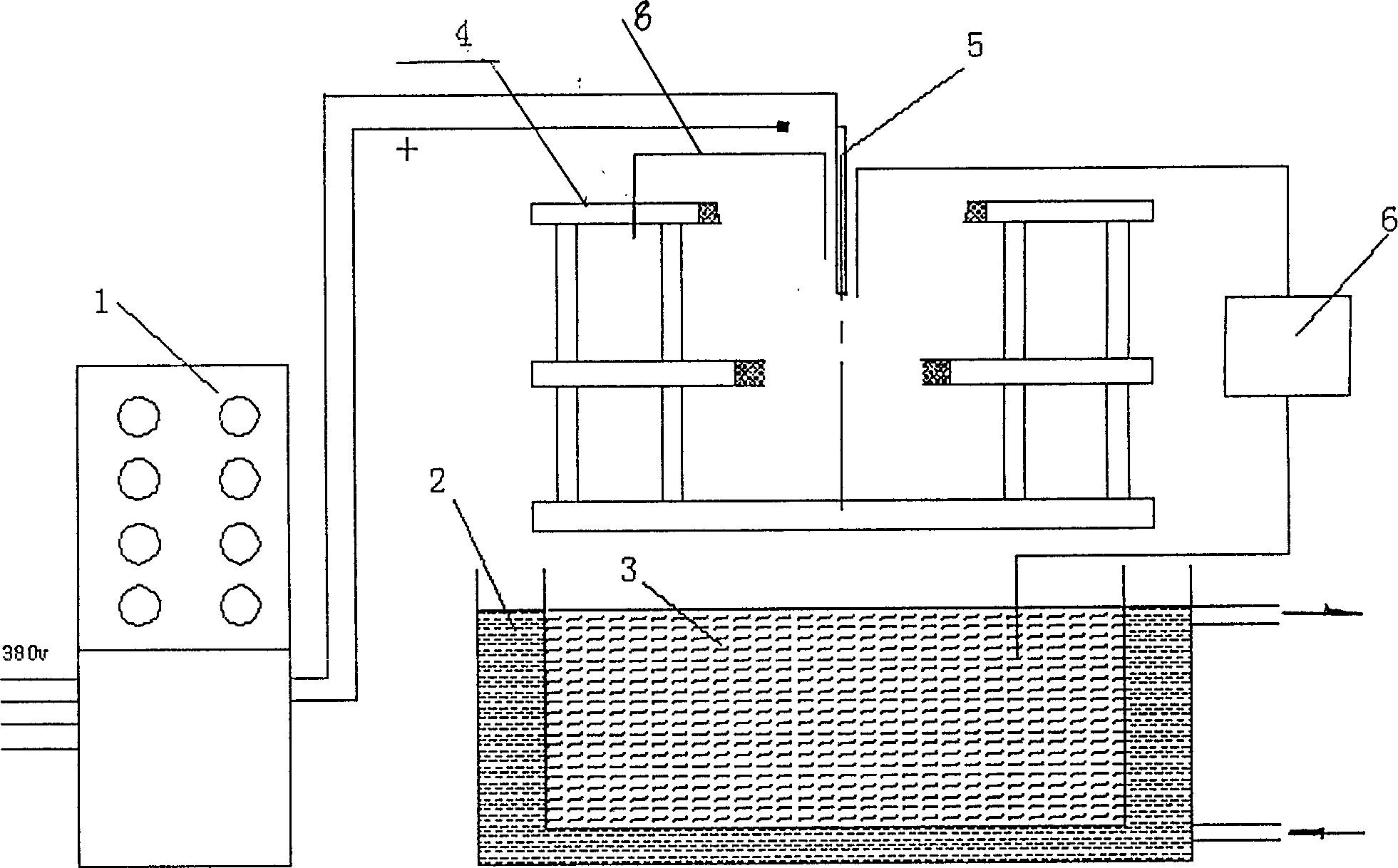

[0029] Embodiment 1, prepare ceramic coating in engine aluminum alloy cylinder body with device and method of the present invention, its steps are as follows:

[0030] 1) Clean and degrease the aluminum alloy cylinder body;

[0031] 2) Pump the electrolyte in the electrolyte storage tank in the cooling pool into the aluminum alloy cylinder, the electrolyte is a sodium phosphate solution, and the concentration of the sodium phosphate solution is 10% by weight; A stainless steel rod in the alloy cylinder is used as the cathode, and the aluminum alloy cylinder is used as the anode, and the asymmetric AC power connected to it is connected.

[0032] The forward current density 10A / dm of the asymmetrical AC power that the present embodiment passes through 2 , negative current density 2.5A / dm 2 .

Embodiment 2

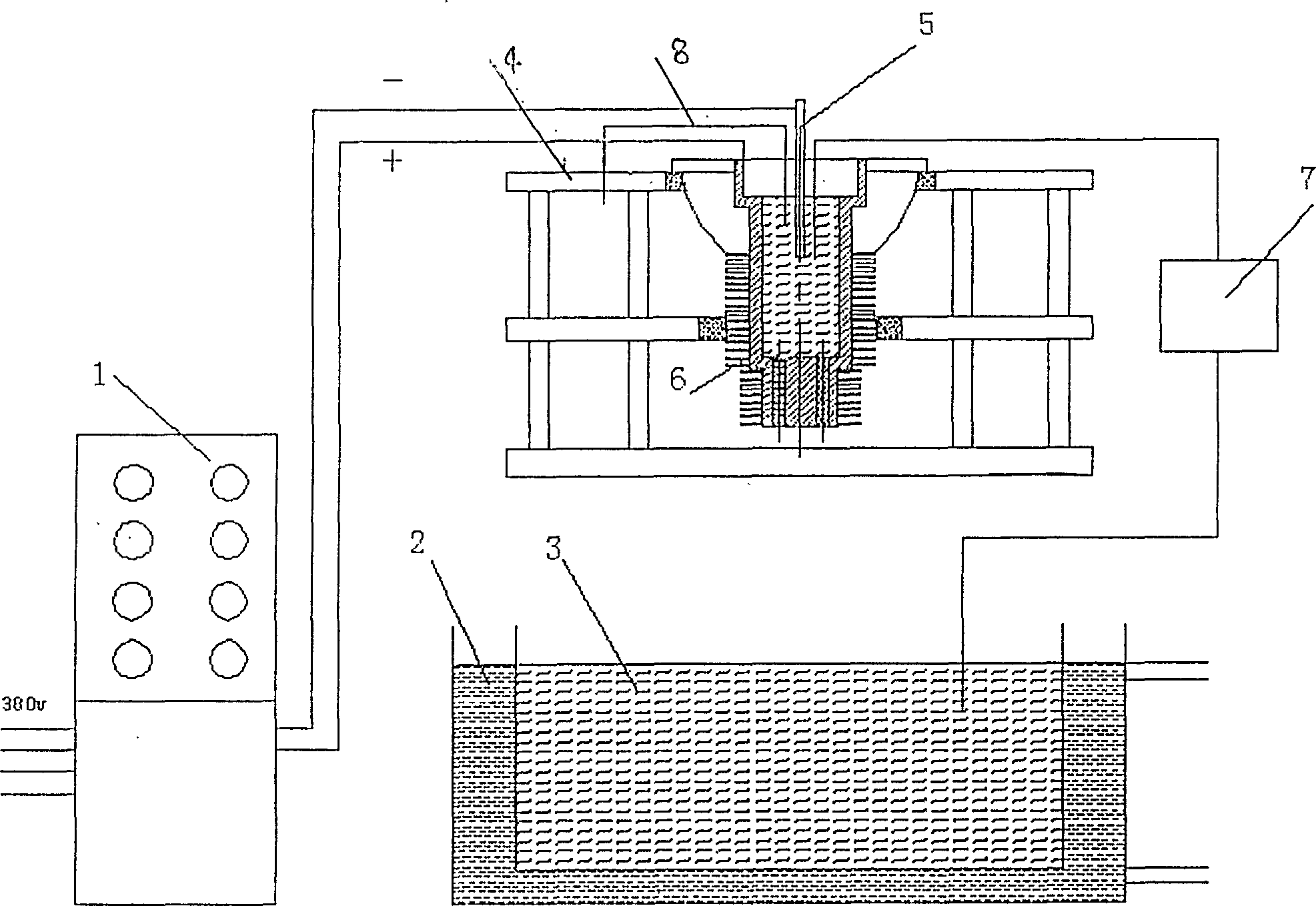

[0033] Embodiment 2, prepare ceramic coating in engine aluminum alloy cylinder body with device and method of the present invention, its steps are as follows:

[0034] 1) Clean and degrease the aluminum alloy cylinder body;

[0035] 2) Pump the electrolyte in the electrolyte storage pool placed in the cooling pool into the aluminum alloy cylinder, the electrolyte is a mixed solution of sodium phosphate solution and sodium borate solution, and its concentration is 10%. The ratio of sodium phosphate content to sodium borate content in the liquid is 98:2; a stainless steel metal rod placed in the aluminum alloy cylinder is used as the cathode, and the aluminum alloy cylinder is used as the anode, and the asymmetric AC connected to it is connected. Power supply, plasma electrolysis for 60 minutes; a layer of 15μm ceramic coating is prepared in the aluminum alloy cylinder.

[0036] The forward current density 10A / dm of the asymmetrical AC power that the present embodiment passes t...

Embodiment 3

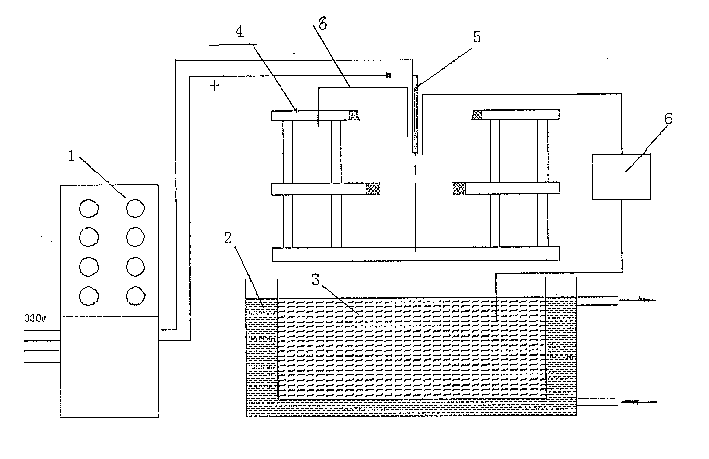

[0037] Embodiment 3, prepare ceramic coating in engine aluminum alloy cylinder body with device and method of the present invention, its steps are as follows:

[0038] 1) Clean and degrease the aluminum alloy cylinder body;

[0039] 2) Pump the electrolyte in the electrolyte storage pool placed in the cooling pool into the aluminum alloy cylinder, the electrolyte is a mixed solution of sodium phosphate solution and sodium borate solution, and its concentration is 10%. The ratio of sodium phosphate content to sodium borate content in the liquid is 95:5; a stainless steel rod placed in the aluminum alloy cylinder is used as the cathode, and the aluminum alloy cylinder is used as the anode, and the asymmetric AC power connected to it is connected. , Plasma electrolysis for 150 minutes; a layer of 50μm ceramic coating is prepared in the aluminum alloy cylinder.

[0040] The forward current density 10A / dm of the asymmetrical AC power that the present embodiment passes through 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com