A special negative pressure vacuum chamber structure for online grinding of cathode rollers

A cathode roller and dust collection chamber technology, applied in grinding machines, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of heavy cathode rollers, low work efficiency, dust and debris falling into the anode tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

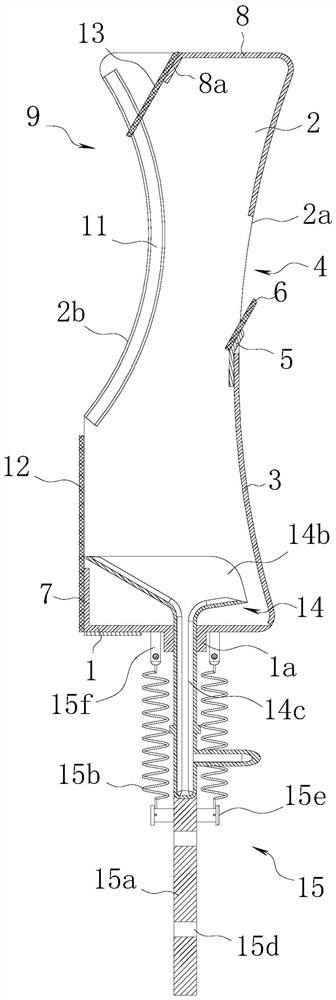

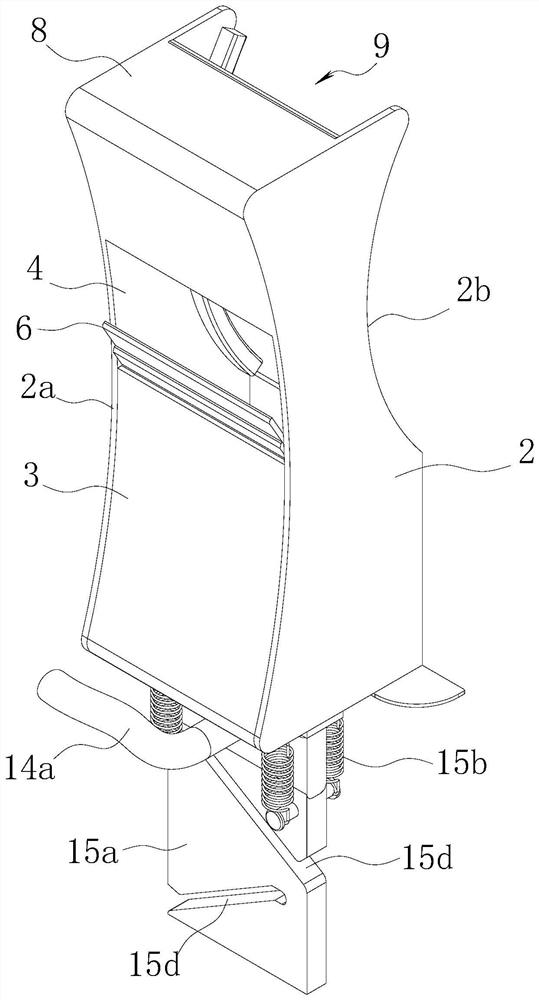

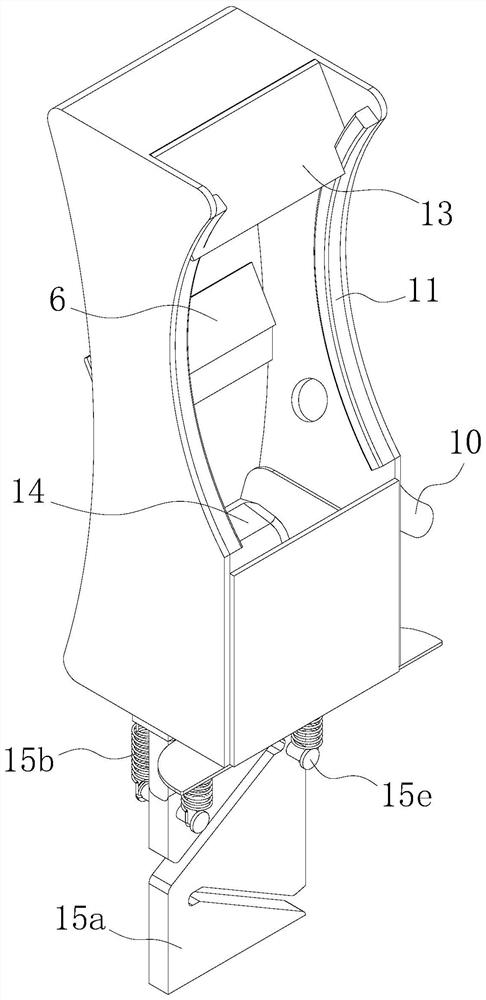

[0023] See Figure 1 to Figure 5 As shown, a negative pressure dust chamber structure dedicated to online grinding of cathode rollers of the present invention includes a bottom plate 1 fixed on a radial sliding seat between a rotating frame 17 and a cathode roller 16. The side plates 2 parallel to each other are arranged vertically, and the two side plates 2 are respectively located on both sides of the rotating frame 17.

[0024] The end surface of the side plate 2 opposite to the cathode roller 16 is a first arc-shaped surface 2a adapted to the cathode roller, and an arc-shaped plate 3 is arranged between the two first arc-shaped surfaces 2a. The radius of the circle where the surface 2a and the arc-shaped plate 3 are located is the same as the radius of the cathode roller; a first relief hole 4 is provided in the middle of the arc-shaped plate 3, and the grinding wheel 18 at the working position extends from the first relief hole and faces The cathode roller 16 is ground.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com