A multi-stage extended trolley

An expandable, trolley technology, applied in the field of trolleys, can solve the problems that the loading area of the cargo platform cannot be well utilized, the carrying and use of the trolley is affected, and the trolley occupies a large space, etc. , the effect of reducing the space occupied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

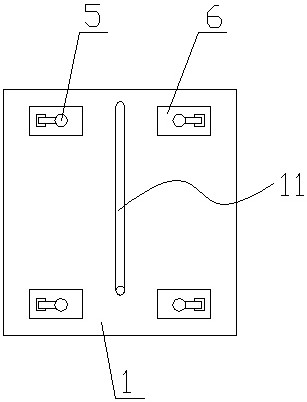

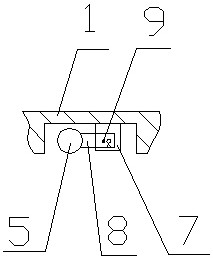

[0049] like Figure 1 to Figure 10 As shown, a kind of multi-stage extended trolley of the present embodiment includes a loading platform, a handrail bar 4 installed on the loading platform for pushing and pulling, and a walking wheel 5 installed on the lower side of the loading platform. The loading platform can be Realize folding expansion, pulling expansion and flipping expansion.

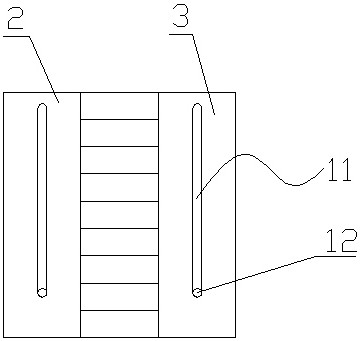

[0050] The folding expansion of the loading platform is realized by the following structure: the loading platform is a folding structure composed of a load-bearing plate 1 and expansion plates arranged on the left and right sides of the load-bearing plate 1, and the expansion plate on the left side of the load-bearing plate is called The left expansion board 2, the left expansion board 2 is hinged on the left edge of the load-bearing board 1, the expansion board located on the right side of the load-bearing board 1 is called the right expansion board 3, the right expansion board 3 is hinged on t...

Embodiment 2

[0067] like Figure 11 As shown, the difference between this embodiment and the first embodiment is that the hinge point between the armrest bar 4 and the load-bearing plate 1 is not only located on the front side of the load-bearing plate, but also the hinge points between the armrest bar 4 and the load-bearing plate 1 are close to the left and right sides respectively. expansion board settings. This design increases the width of the handrail bar, which is convenient for controlling the walking of the push-pull trolley and improves the working stability.

Embodiment 3

[0069] like Figure 12 and 13 As shown, the difference between this embodiment and the first embodiment is that the handlebar 4 is a U-shaped structure assembled and assembled by a pull rod 41, an extension rod 42 and a handle rod 43, and the pull rod 41 is provided with two and They are hingedly connected with the bearing plate 1 respectively, and at least two extension rods 42 and pull rods 41 are correspondingly provided with at least two, and the extension rods 42 are detachably connected to the extension line of the tail of the pull rods 41; Both ends of the handle bar 43 are detachably connected to the corresponding pull bar 41 or extension bar 42 respectively.

[0070] In this embodiment, the extension rod 42 is inserted into the tail of the corresponding pull rod 41, and is fixed by a hoop or a fastening bolt that penetrates horizontally; the two ends of the handle bar 43 are inserted into the corresponding pull rod 41 or extended The rod 42 is fixed by a hoop or a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com