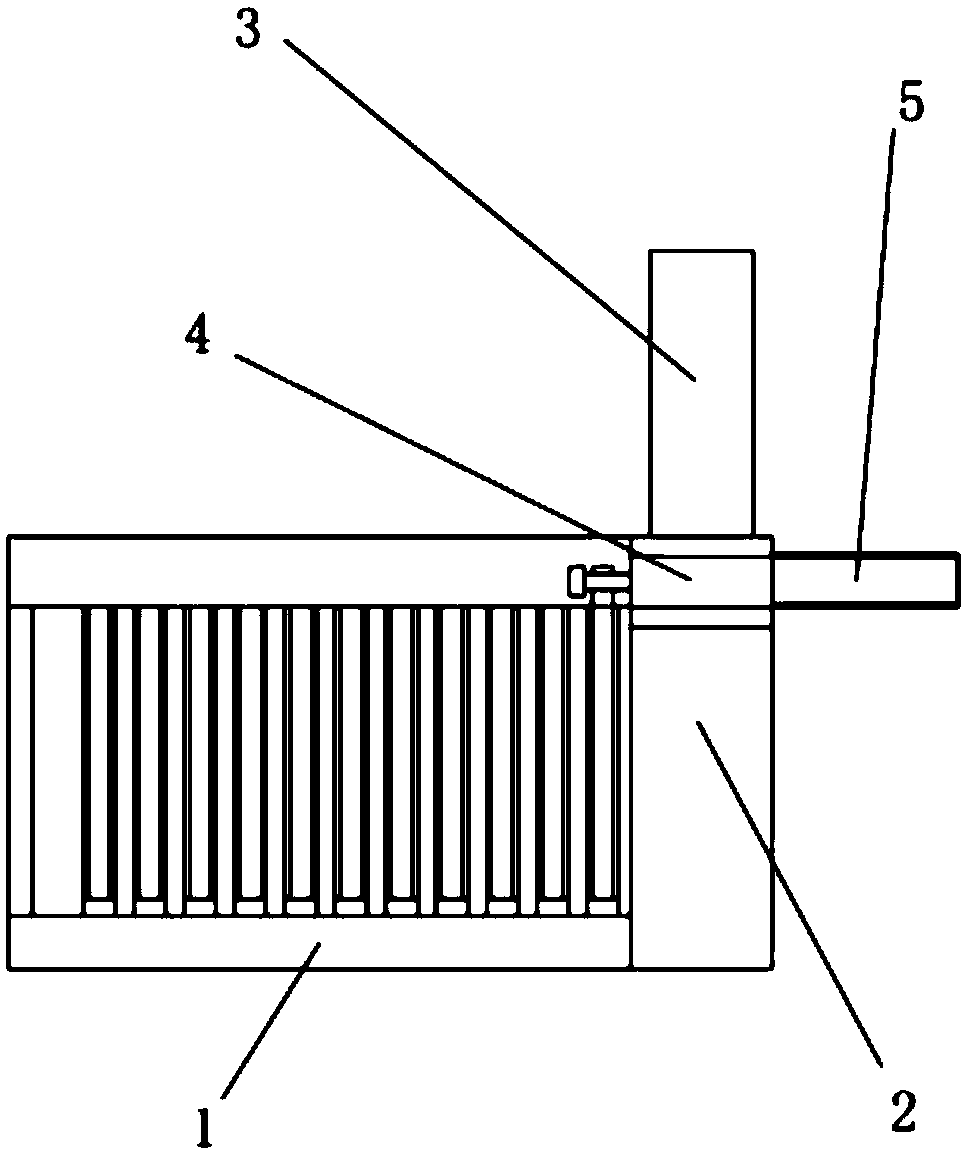

Automatic loading device for water pump rotor

A technology of automatic feeding and water pump rotor, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of large volume of water pump rotor and unfavorable feeding, etc., and achieve the control of blanking efficiency, fast discharge speed and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

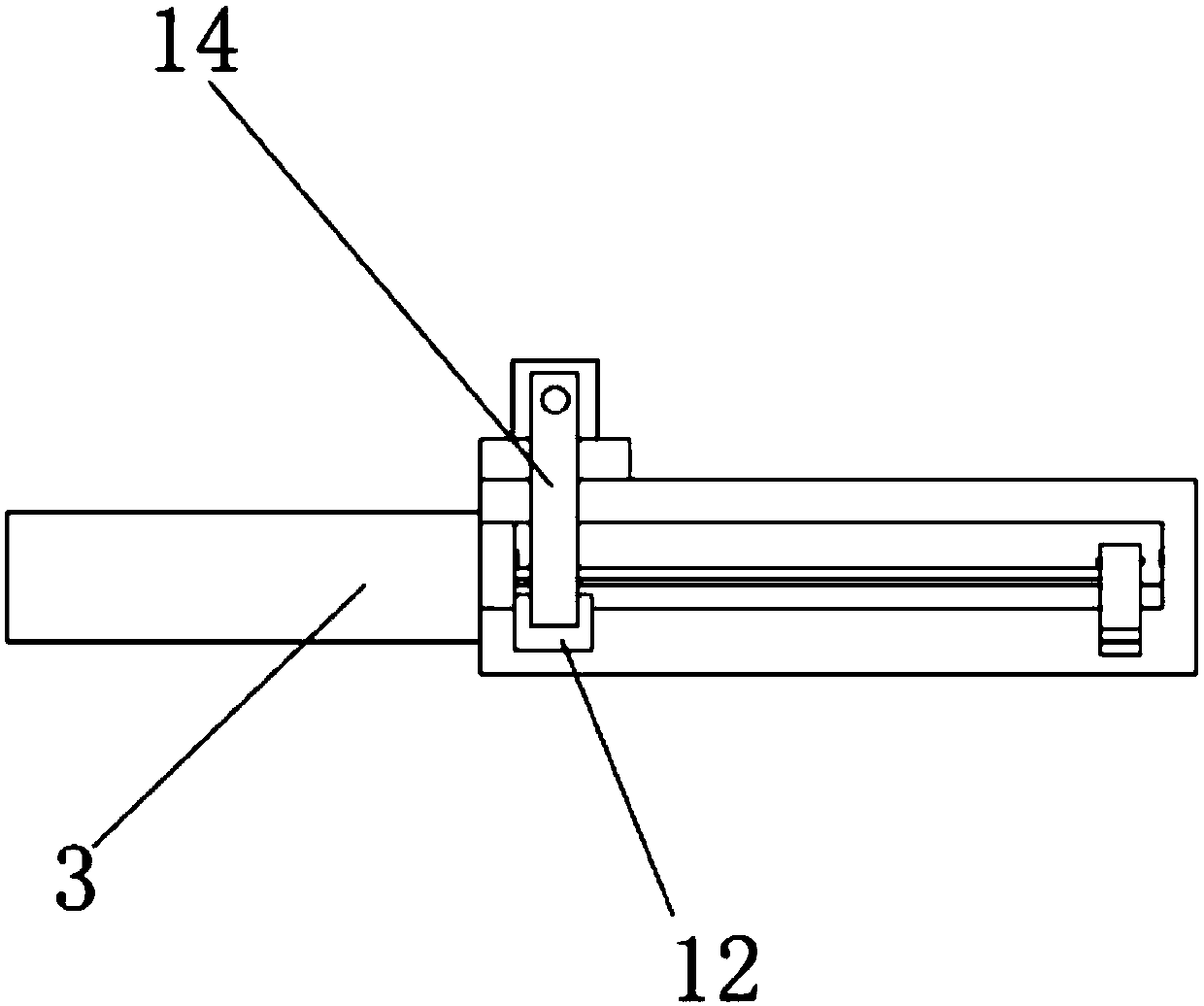

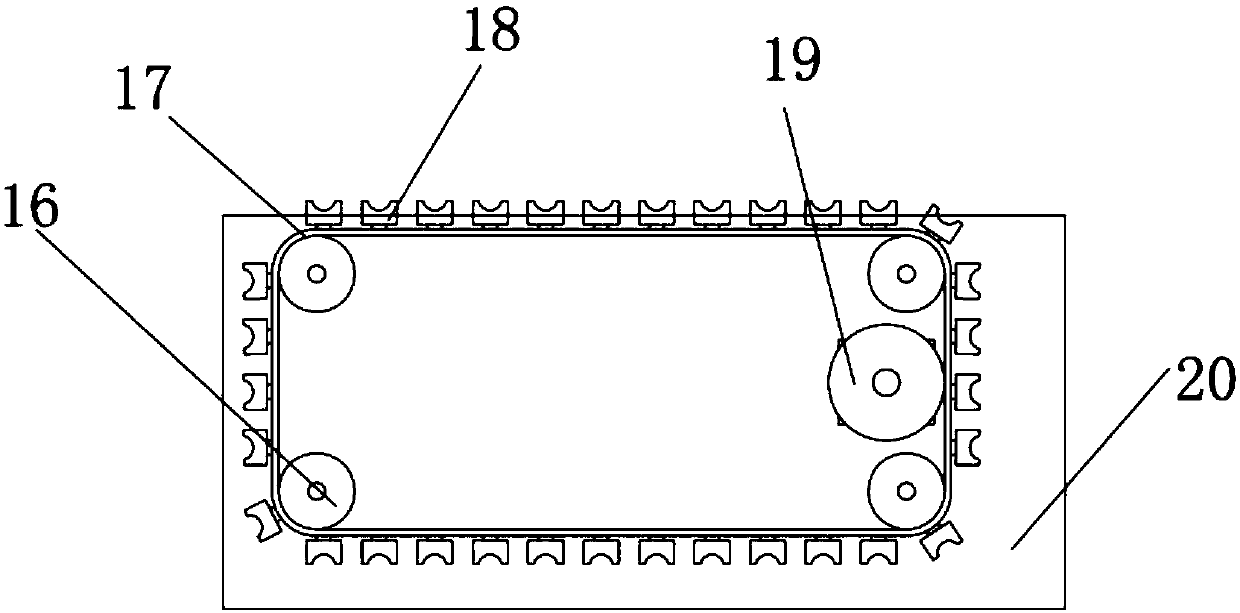

Embodiment

[0029] When loading materials, the worker first puts the rotors one by one into the arrangement arc groove 23 of the arrangement fixture 18. When carrying out material loading, the loading rack 2 first senses that the arrangement fixture 18 brings the rotors into the unloading position , then stop the servo motor 22, start the toggle cylinder 3, the toggle block 10 is driven by the toggle cylinder 3 to move backward, the toggle block 10 toggles a row of rotors to move backward, and the last rotor enters the rotor positioning groove 6 and then dials The moving cylinder 3 stops, the unloading cylinder 4 starts, and the ejector rod of the unloading cylinder 4 shrinks, so that the unloading block 14 moves the rotor into the discharge port 12, and enters the discharge chute 5 through the discharge port 12 , after completion, the unloading cylinder 4 resets, then starts the toggle cylinder 3, repeats the above-mentioned actions, until after a row of rotors are all transported, the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com