Cement silo clearing device and silo clearing method

A cement and warehouse cleaning technology, applied in the field of machinery, can solve the problems of low efficiency, high physical harm to workers, high risk to life, etc., to achieve high work efficiency, avoid the danger of suspended work, and take up less space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

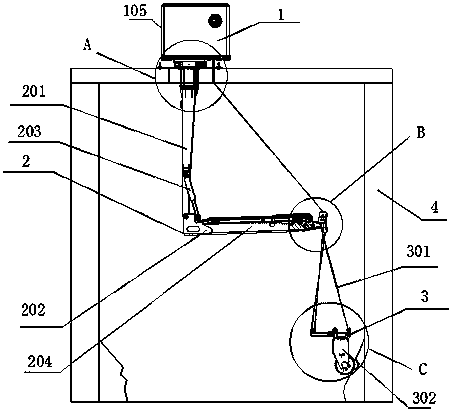

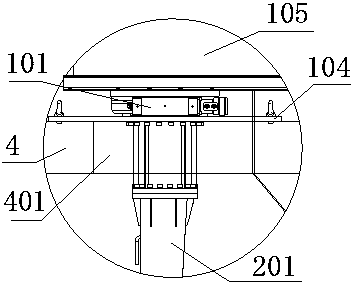

[0037] Such as Figure 1-5 As shown, the cement warehouse cleaning device includes a top fixing mechanism 1, a mechanical arm 2 connected to the lower end of the top fixing mechanism 1, and a power mechanism 3 installed on the mechanical arm 2;

[0038] Described mechanical arm 2 comprises mechanical revolving arm 201 and mechanical telescoping arm 202, is rotatably connected between one end of mechanical revolving arm 202 and top fixing mechanism 1, and mechanical revolving arm 202 is driven by the rotating motor that is installed on the top fixing mechanism 1 101 drives the rotation, the other end of the mechanical revolving arm 201 is hinged with the mechanical telescopic arm 202, and the rotation between the mechanical telescopic arm 202 and the mechanical revolving arm 201 is controlled by the folding device 203 installed on the mechanical revolving arm 201;

[0039] The power mechanism 3 includes a lifting mechanism 301 and a power head 302. The lifting mechanism 301 is ...

Embodiment 2

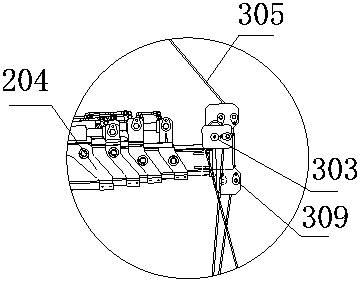

[0055] Such as Figure 6 , Figure 7 As shown, in this embodiment, on the basis of Embodiment 1, the rope 305 extends to the winch 102 through the hollow channel 205 of the mechanical slewing arm 201. If it enters the installation box 105 directly from the opening on the top of the cement silo, The rope 305 will be in contact with the wall at the hole, and the requirements for the hole are very high. It needs to be polished to avoid serious wear of the rope 305. Now it directly enters the hollow to 205, and then there will be friction between the rope and the mechanical rotating arm 201. The embodiment is that an inlet is set on the side wall of the mechanical swing arm 201, and an outlet is set at the upper end of the mechanical swing arm 201, so we process it into a smooth edge at the entrance, so that the wear of the rope 305 is very little.

Embodiment 3

[0057] Such as Figure 8 , Figure 9 As shown, in this embodiment, on the basis of Embodiment 2, two pulleys clamp the rope 305 at the entrance of the lower end of the hollow passage 205 to facilitate the movement of the rope 305. In this embodiment, two pulleys clamp the rope 305 directly. 305, when the rope 305 is in motion, it will not rub against the edge of the entrance, which protects the rope 305.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com