Lithium-ion secondary battery, separator and preparation method thereof

A technology of secondary batteries and separators, applied in secondary batteries, battery pack components, circuits, etc., to avoid combustion and explosion, reduce deformation problems, and avoid short circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

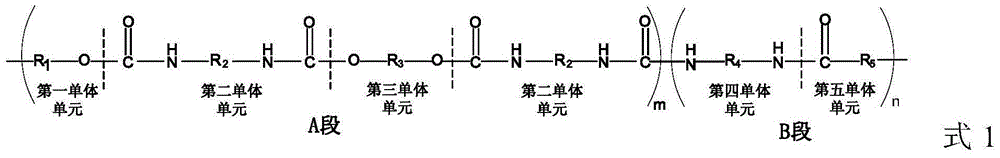

Method used

Image

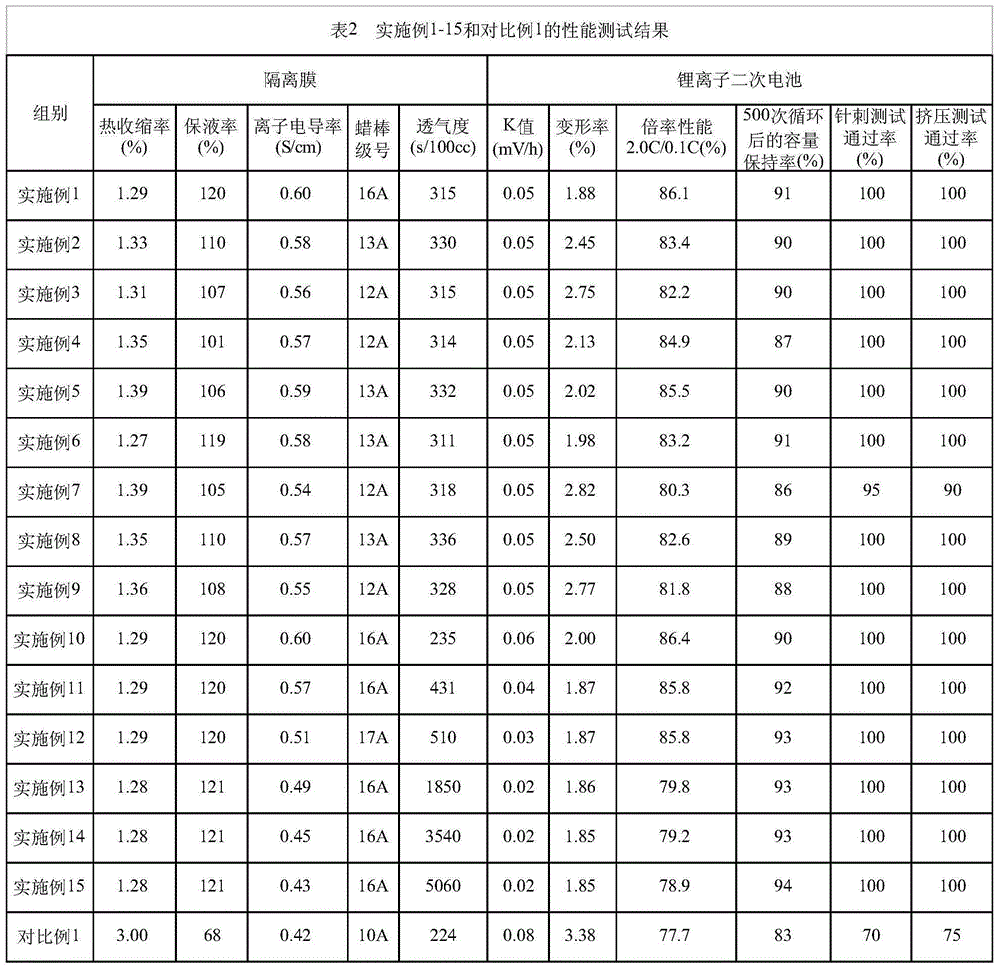

Examples

preparation example Construction

[0029] The preparation method of the separator of the lithium ion secondary battery according to the second aspect of the present invention is used to prepare the separator of the lithium ion secondary battery according to the first aspect of the present invention, comprising the steps of: (1) mixing an organic solvent, The catalyst is added to a three-port reaction kettle with a temperature sensor, a condensing reflux pipe, and a stirring paddle, and then the first monomer, the second monomer, and the third monomer are added to the three-port reaction kettle while stirring, and the reaction is stirred at room temperature. Then heat up and continue to stir the reaction to obtain the A section with isocyanate groups at the end; (2) add the aprotic polar solvent to another three-port reaction kettle with a temperature sensor, a condensing reflux pipe, and a stirring paddle and heat up, and then to the In another three-port reactor, add the fourth monomer and the fifth monomer whi...

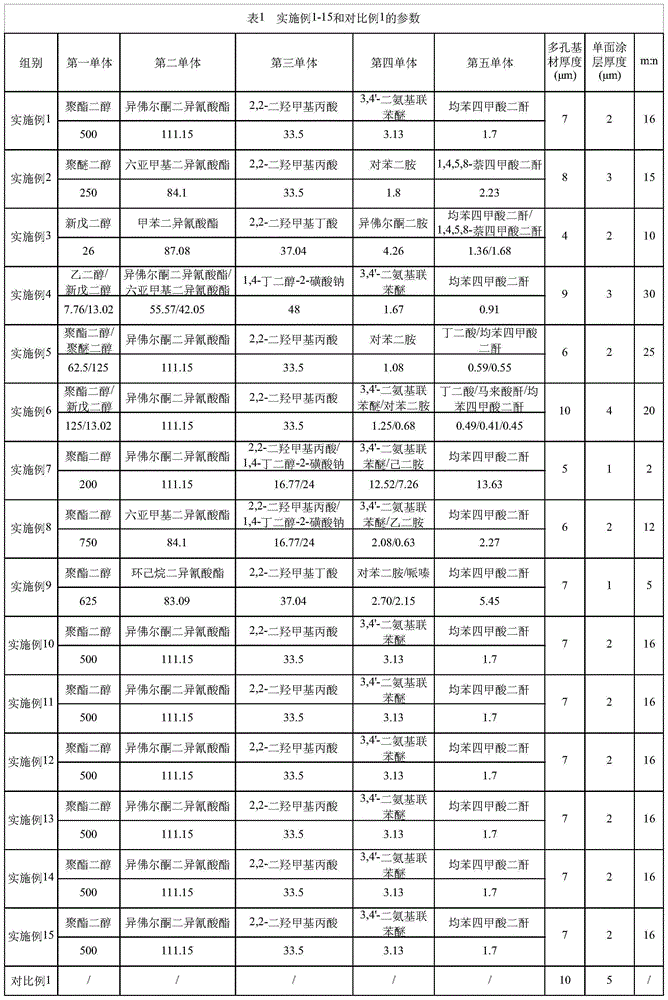

Embodiment 1

[0044] 1. Preparation of separator for lithium-ion secondary batteries

[0045] (1) Add 200 mass parts of rectified organic solvent methyl ethyl ketone and 0.1 mass part of catalyst organotin into a three-port reaction kettle with a temperature sensor, a condensation reflux pipe, and a stirring paddle, and then stir in the three-port reaction kettle Add 500 parts by mass of polyester diol (the first monomer) with a weight average molecular weight of 2000 and 33.50 parts by mass of 2,2-dimethylolpropionic acid (the third monomer), then slowly drop 111.15 parts by mass of iso For pherone diisocyanate (the second monomer), first stir and react at room temperature for 1 h, then stir and react at 80°C for 4 h to obtain segment A with an isocyanate group at the end;

[0046] (2) At the same time, add the aprotic polar solvent N-methylpyrrolidone of 3.2 parts by mass of rectification into another three-port reactor with a temperature sensor, a condensing reflux pipe, and a stirring p...

Embodiment 2

[0059] Lithium-ion secondary batteries were prepared according to the method of Example 1, except that in the step of preparing the separator of lithium-ion secondary batteries (i.e. step 1), the first monomer was 250 parts by mass of polyether disulfide with a weight-average molecular weight of 1000. alcohol, the second monomer is 84.10 parts by mass of hexamethylene diisocyanate, the fourth monomer is 1.80 parts by mass of p-phenylenediamine, and the fifth monomer is 2.23 parts by mass of 1,4,5,8-naphthalene Tetraformic dianhydride; the thickness of the porous substrate is 8 μm, the thickness of the coating on one side is 3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com