Water-cooled plate heat exchanger with circular structure

A water-cooled plate and heat exchanger technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc. Control and other issues to prevent the temperature of the heat source from being too low, reduce the flow dead zone, and facilitate heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present disclosure will be further described below in conjunction with the accompanying drawings and specific embodiments.

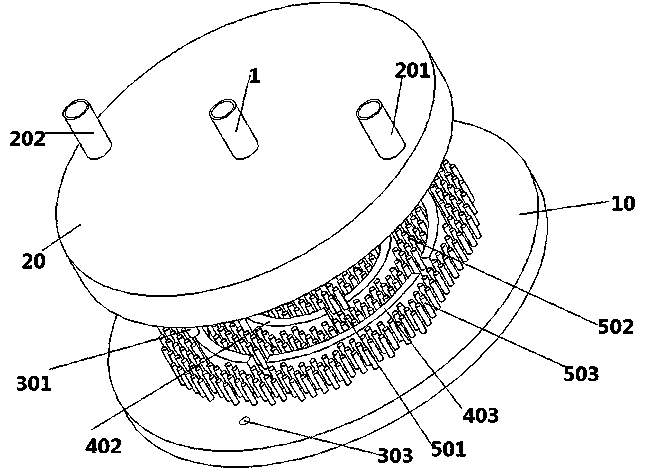

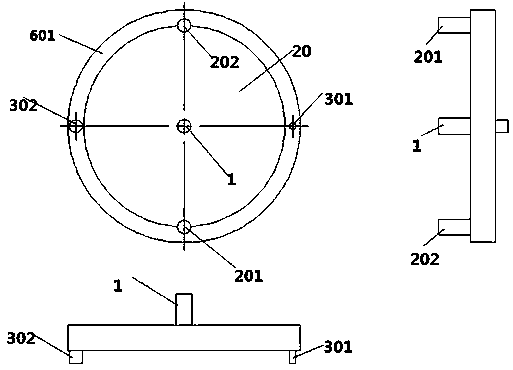

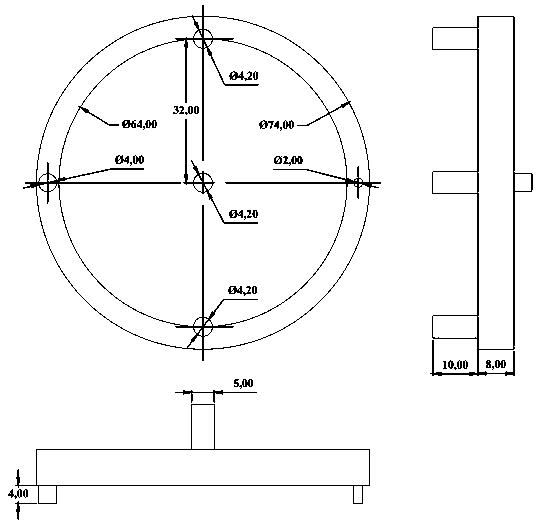

[0045] Such as Figure 1-3 A water-cooled plate heat exchanger with a circular structure is shown, including a base plate 10 and a cover plate 20. The base plate 10 and the cover plate 20 are of circular structure, and the cover plate 20 and the base plate 10 are assembled together to form a circular cavity. Cooling fluid (preferably water) flows in the cavity, and baffles 401-403 and cylindrical fins 501-503 are arranged on the substrate 10, the baffles include the first baffle 401 located in the center of the substrate, surrounded by the first The second baffle plate 402 outside the baffle plate 401 and the third baffle plate 403 surrounding the outside of the second baffle plate 402; the first baffle plate, the second baffle plate, and the third baffle plate are circular arcs with the center point of the substrate as the center structure; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com