Ultrasonic flaw detection system for nuclear-grade stainless steel outer sleeve and flaw detection method thereof

A stainless steel and ultrasonic technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, and measuring devices to achieve the effects of ensuring water coupling stability, small process changes, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

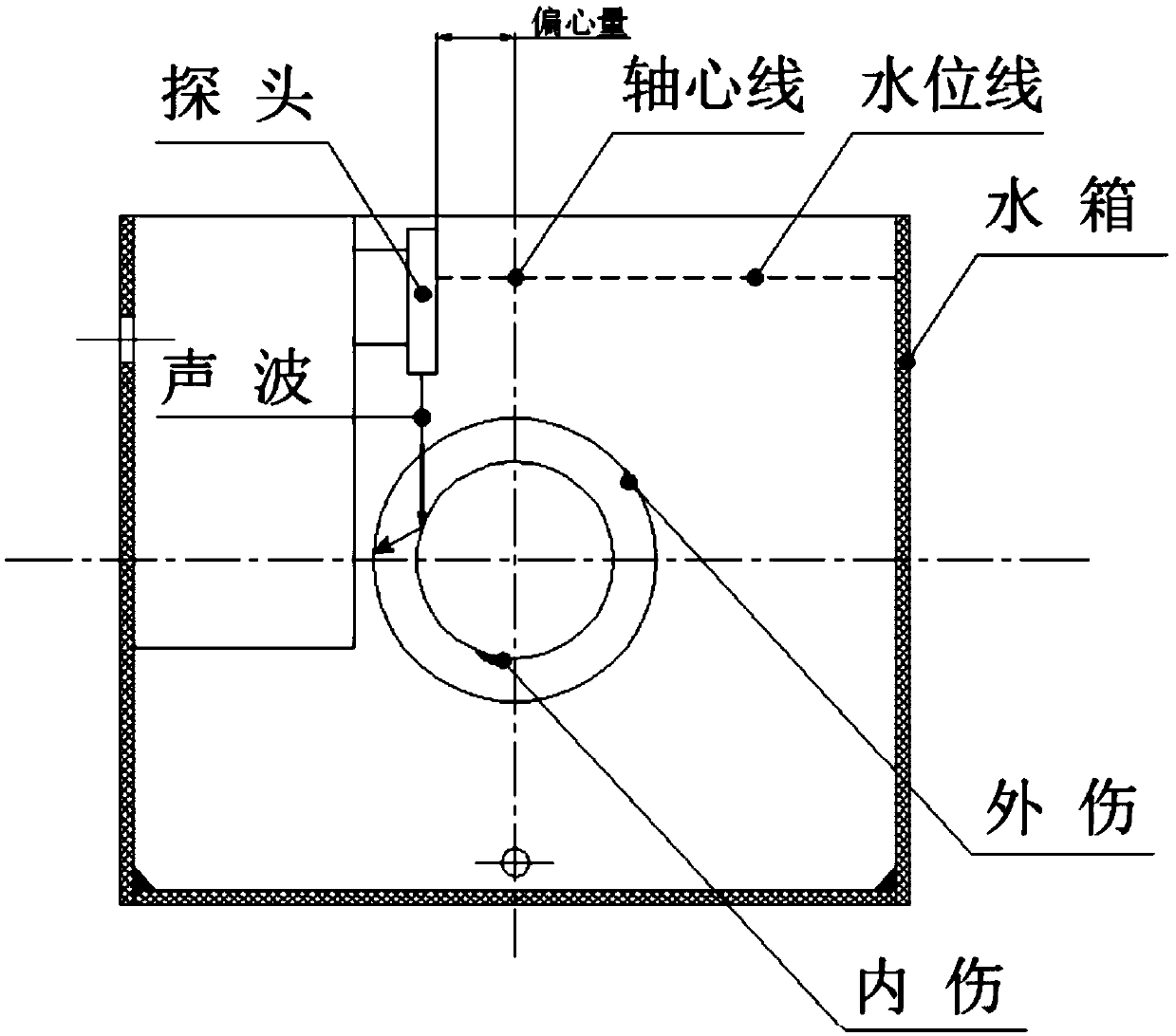

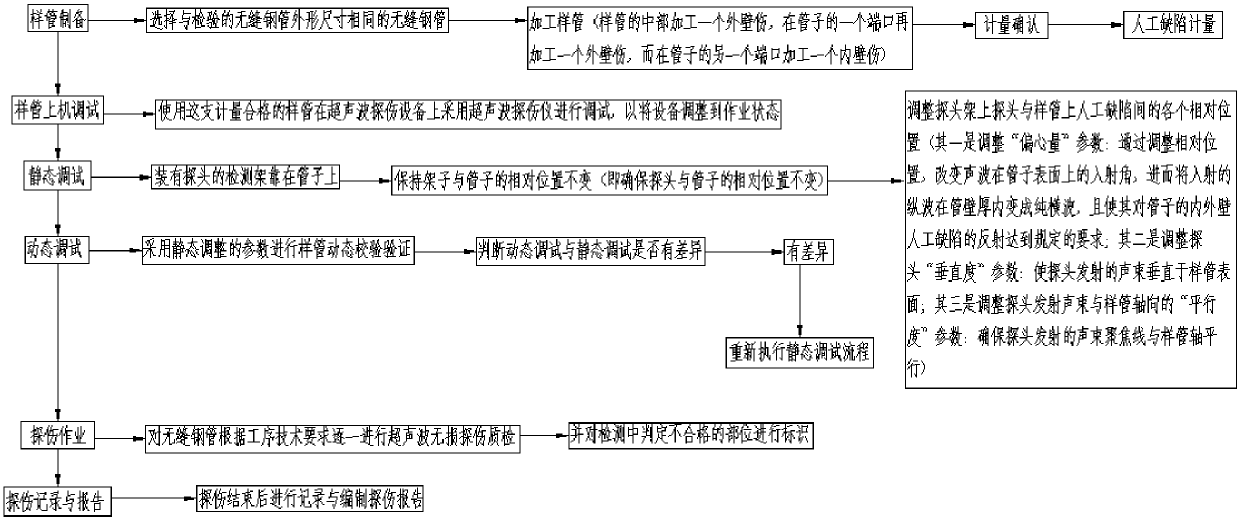

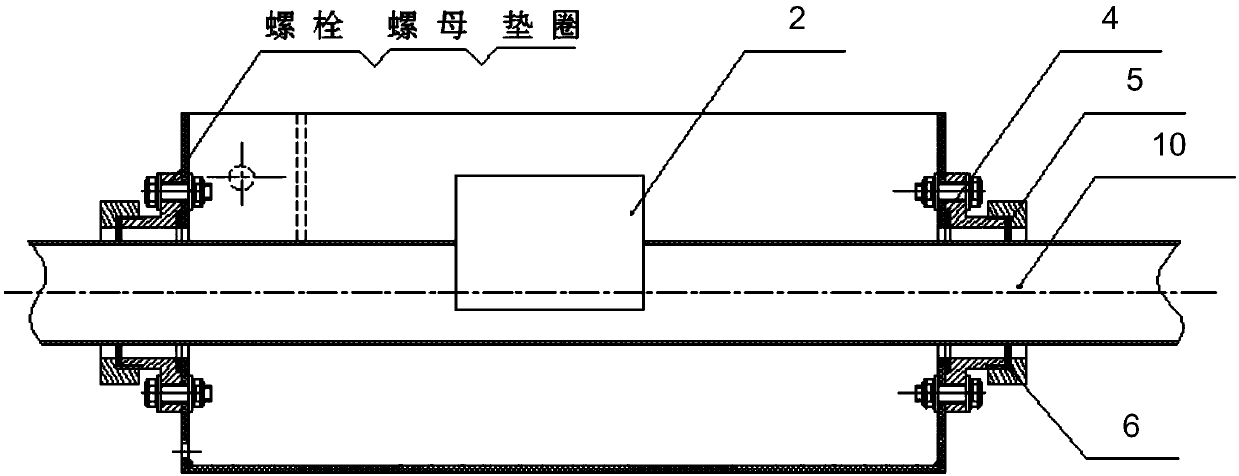

[0071] Taking the steel grade of 0Cr17Ni12Mo2Ti (316Ti) and φ68.3*1.3mm seamless steel pipe as an example, the process method (process flow) of single-channel ultrasonic flaw detection is as follows:

[0072] 1) Preparation of the sample tube. The seamless steel tube with the same external dimensions as the nuclear-grade stainless steel seamless steel tube is processed into a sample tube for ultrasonic flaw detection. An outer wall flaw is processed in the middle of the sample tube, and an outer wall is processed at one port of the sample tube. For flaws, an inner wall flaw is processed on the other port of the sample tube. The dimensions (depth, width, and length) of these three artificial defects are processed according to the product requirements. After the sample tube is processed, it needs to be measured to determine whether it meets the standard requirements;

[0073] 2) The sample tube is debugged on the machine, and the sample tube obtained in step 1) is debugged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com