Flexible straight-down backlight device and display equipment

A backlight device, direct type technology, applied in nonlinear optics, optics, instruments, etc., can solve the problems of difficult implementation of flexible Mini-LED backlight technology, low light output efficiency, loss of return light efficiency, etc., to improve light output uniformity. and light energy utilization efficiency, overcome the uneven brightness and darkness, and expand the effect of diffusion angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

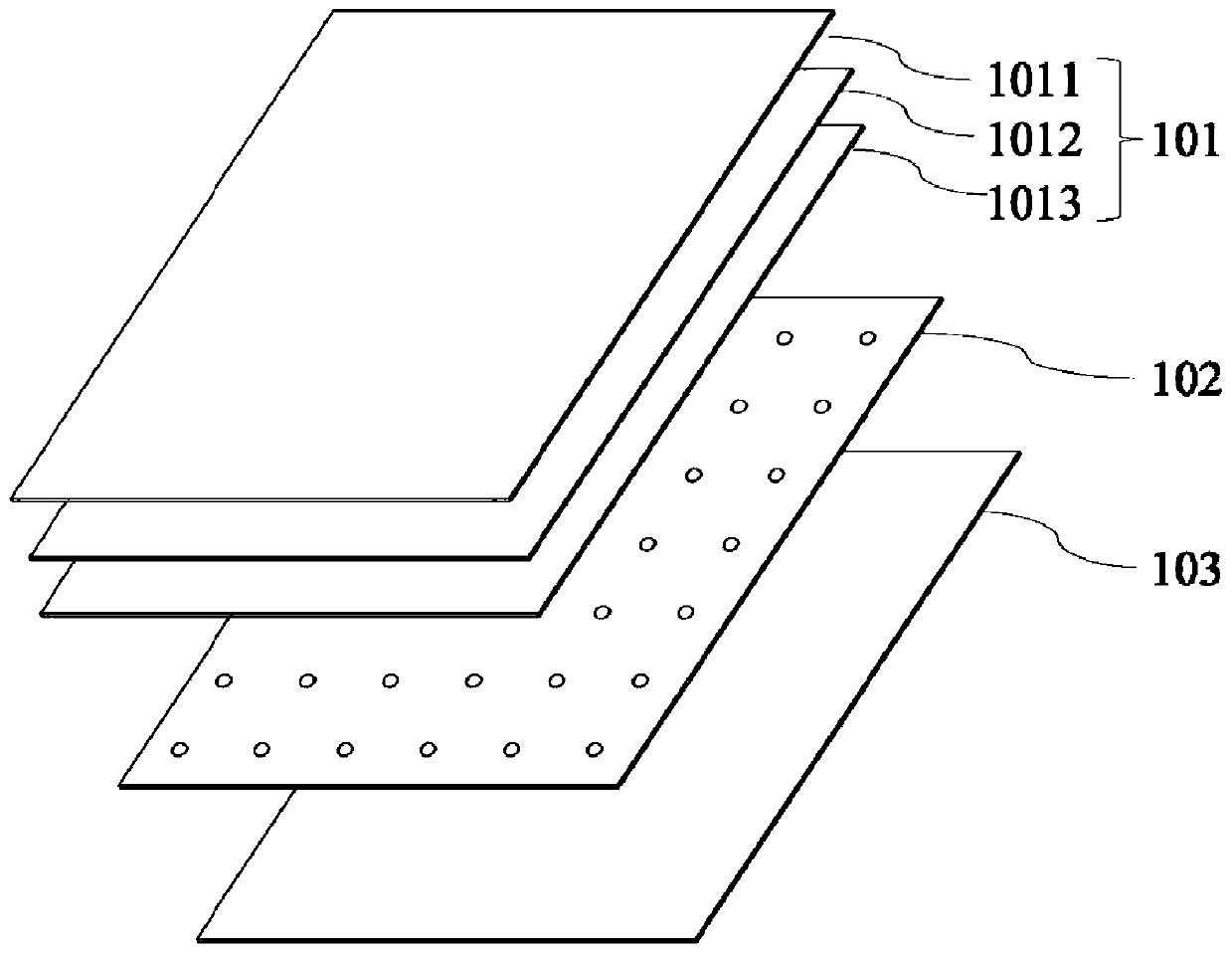

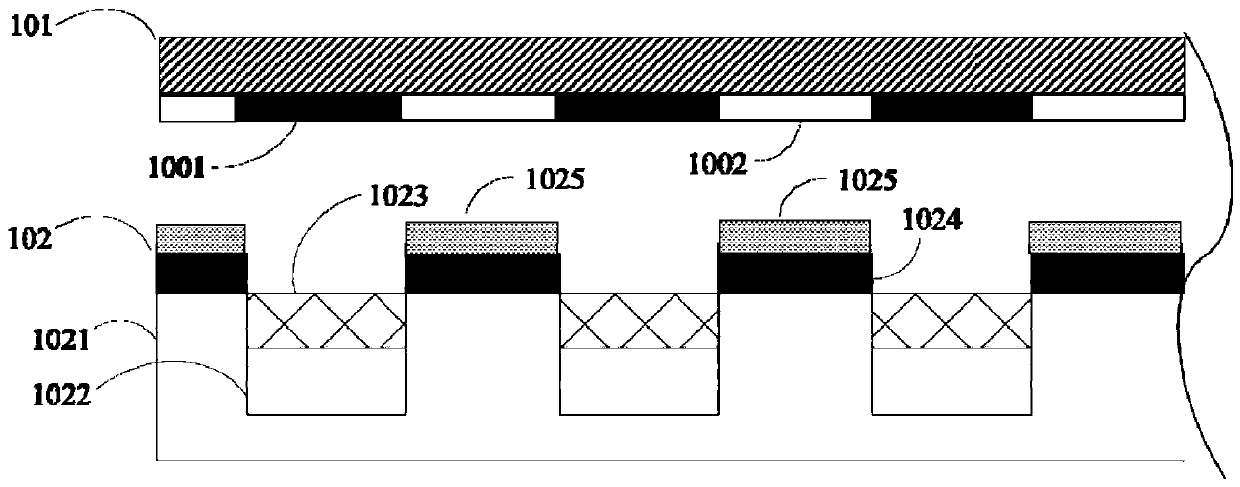

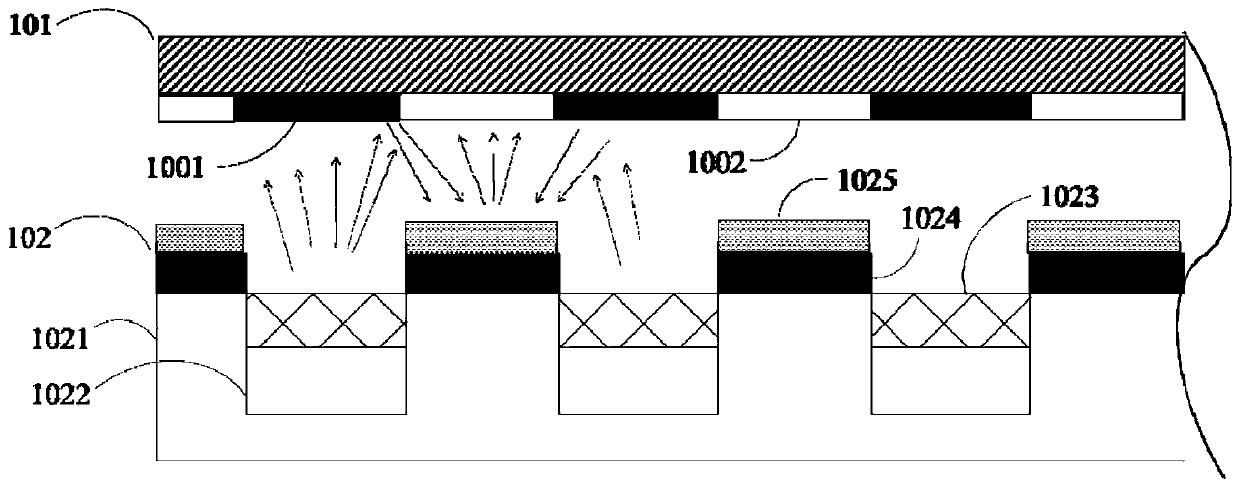

[0031] First, through Figure 1-3, the flexible direct-lit backlight device according to Embodiment 1 of the present invention will be described. One technical solution adopted by the present invention is to provide a flexible direct-lit backlight device, which includes an optical film set 101 , a mini-LED lamp board 102 and an FPC drive board 103 arranged from top to bottom. The FPC driving board 103 is electrically connected to the mini-LED lamp board 102 . The mini-LED light board 102 includes a flexible polyimide film 1021 , a mini-LED chip 1022 and a fluorescent layer 1023 encapsulating the mini-LED chip 1022 . Such as figure 2 As shown, the lower surface of the optical film group 101 is provided with a first reflective structure 1001 , and the first reflective structure 1001 corresponds to the mini-LED chip 1022 . The mini-LED lamp panel 102 also includes a second reflective structure 1024, and the second reflective structure 1024 is arranged alternately with the fir...

Embodiment 2

[0042] Please refer to Figure 4 , is a partial cross-sectional view of the mini-LED lamp panel of the flexible direct-lit backlight device according to Embodiment 2 of the present invention. Only the differences between Embodiment 2 and Embodiment 1 will be described below, and the similarities will not be repeated here.

[0043] The second reflective structure 1024 is disposed on the side between the mini-LED chip 1022 and the fluorescent layer 1023 . The fluorescent layer 1023 replaces the function of the protective protrusions to increase the optical path of the reflected light, and the fluorescent layer 1023 is filled with diffusion particles.

Embodiment 3

[0045] Please refer to Figure 5 , is a partial cross-sectional view of the mini-LED lamp panel of the flexible direct-lit backlight device according to Embodiment 3 of the present invention. In the following, only the differences between Embodiment 3 and Embodiment 1 will be described, and the similarities will not be repeated here.

[0046] The second reflective structure 1024 is disposed on the lower side of the mini-LED chip 1022 . Likewise, this setting increases the distance between the first reflective structure 1001 and the second reflective structure 1024, further increases the optical distance and efficiency of light mixing, and improves the uniformity of light output. The fluorescent layer 1023 replaces the function of the protective protrusions to increase the optical path of the reflected light, and the fluorescent layer 1023 is filled with diffusion particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com