A metal reactor internals suitable for spherical fuel and high temperature coolant

A technology for high-temperature cooling and spherical fuel, which is applied in the field of metal stack internals suitable for spherical fuel and high-temperature coolant, can solve the problems of displacement of graphite components and metal components, large differences in expansion coefficients, etc., to prevent displacement problems, Ease of manufacture and installation, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

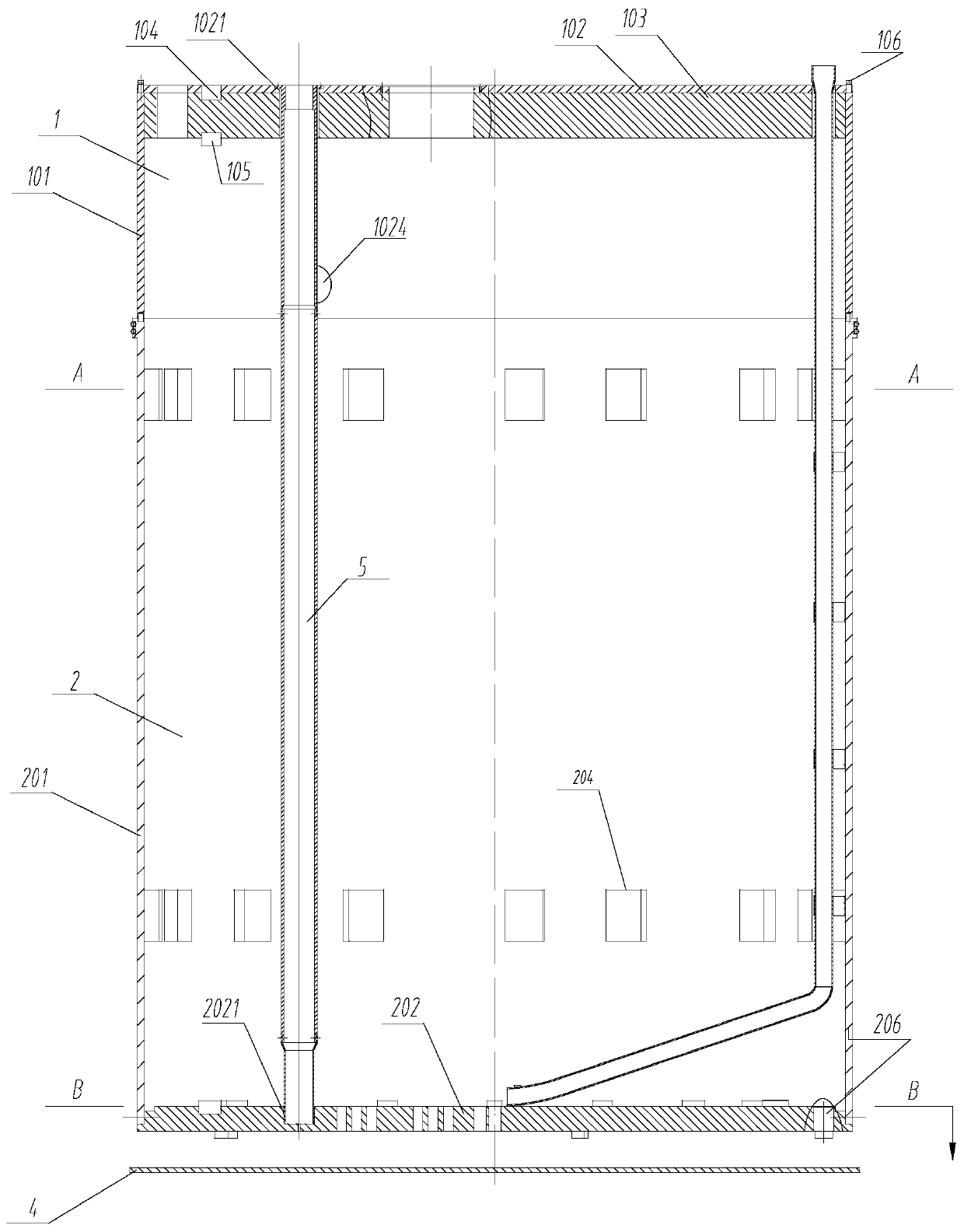

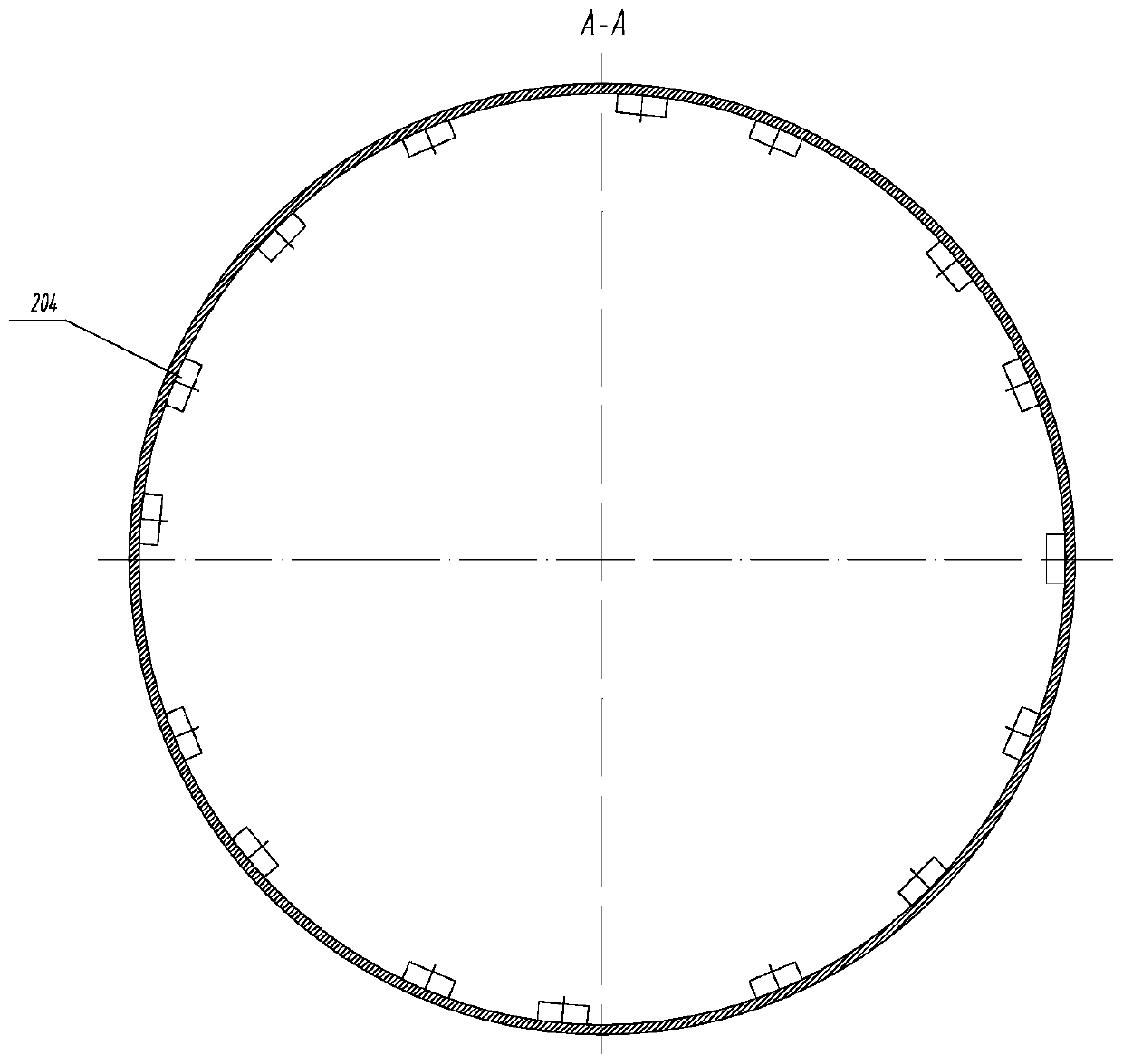

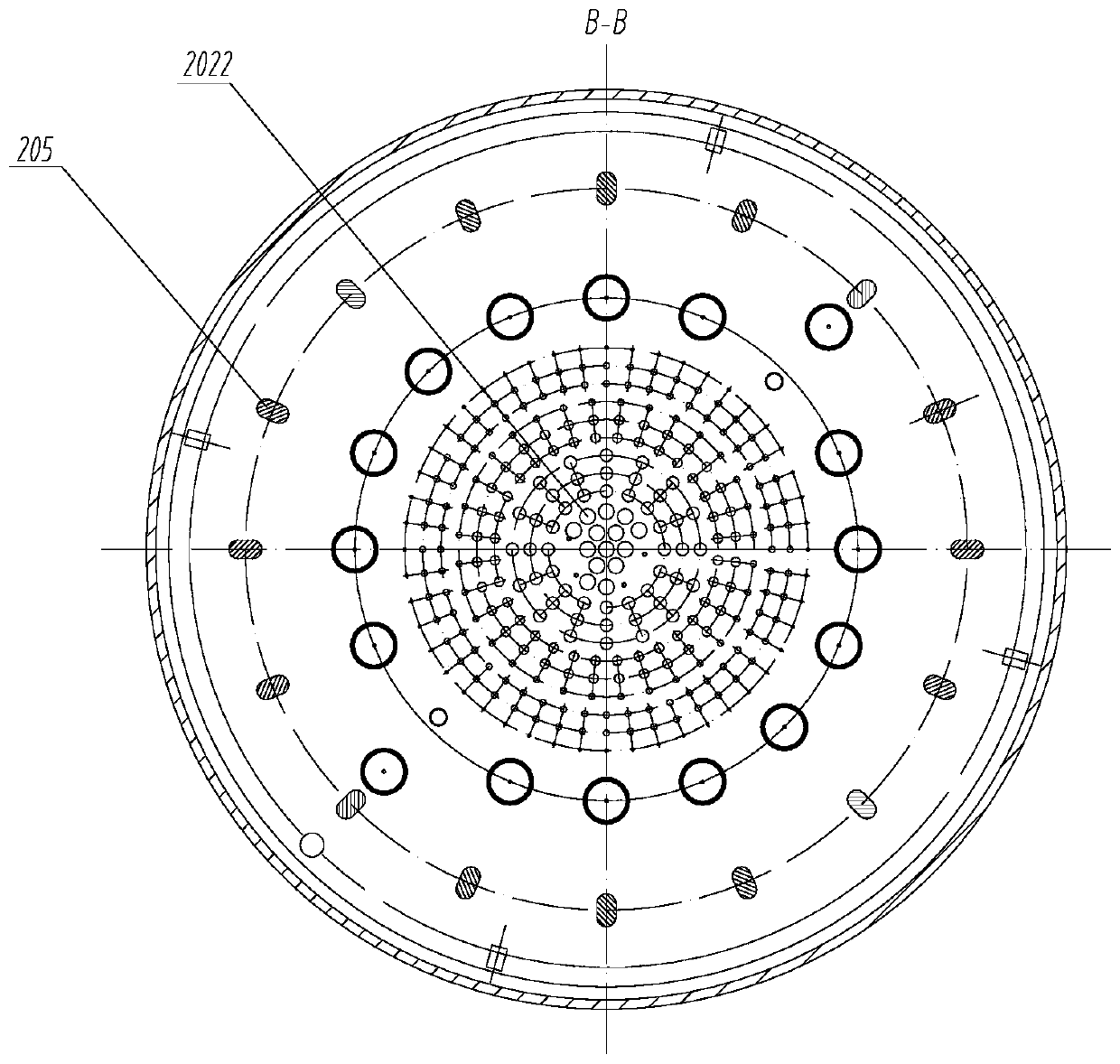

[0035] Such as figure 1 , 2 , 3, and 4, a metal internals suitable for spherical fuel and high-temperature coolant, including an upper shroud assembly 1 arranged on the upper part, and a core shroud assembly 2 arranged below the upper shroud 101 parts, The upper shroud assembly 1 and the core shroud assembly 2 are positioned and connected through a plurality of positioning pins 3 arranged along the circumferential direction, and the upper shroud assembly 1 is provided with an axially limiting upper layer under the compression plate 102 . An axial positioning device for graphite, the core shroud assembly 2 includes a core shroud 201, the inner wall of the core shroud 201 is provided with more than two circumferential limiting layers arranged in parallel up and down along the axial direction, and the circumferential limiting layers The layer is composed of a plurality of circumferential limiting members arranged along the inner wall of the core shroud 201 , and more than two ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com